A kind of olefin polymer and its preparation method and application

A technology of olefin polymers and polymerization reactions, applied in the field of olefin polymers, can solve problems such as not being able to meet the requirements of impact strength and glossiness at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of olefin polymer provided by the invention comprises the following steps:

[0029] (1) Under an inert gas environment, the monofunctional organolithium initiator and the conjugated diene monomer are carried out in an inert solvent for the first polymerization reaction;

[0030] (2) When the conversion rate of the conjugated diene monomer is more than or equal to 97%, the first polymerization product is subjected to a coupling reaction with a multifunctional coupling agent; the total coupling in the multifunctional coupling agent is The molar ratio of the linking group to the monofunctional organolithium initiator is 0.40-0.55:1;

[0031] (3) In the presence of a terminator, the product obtained in step (2) is subjected to a second polymerization reaction with the monovinylarene monomer, so that the conversion rate of the monovinylarene monomer is ≥ 97%; the termination The molar ratio of the catalyst to the monofunctional organolithium initiator...

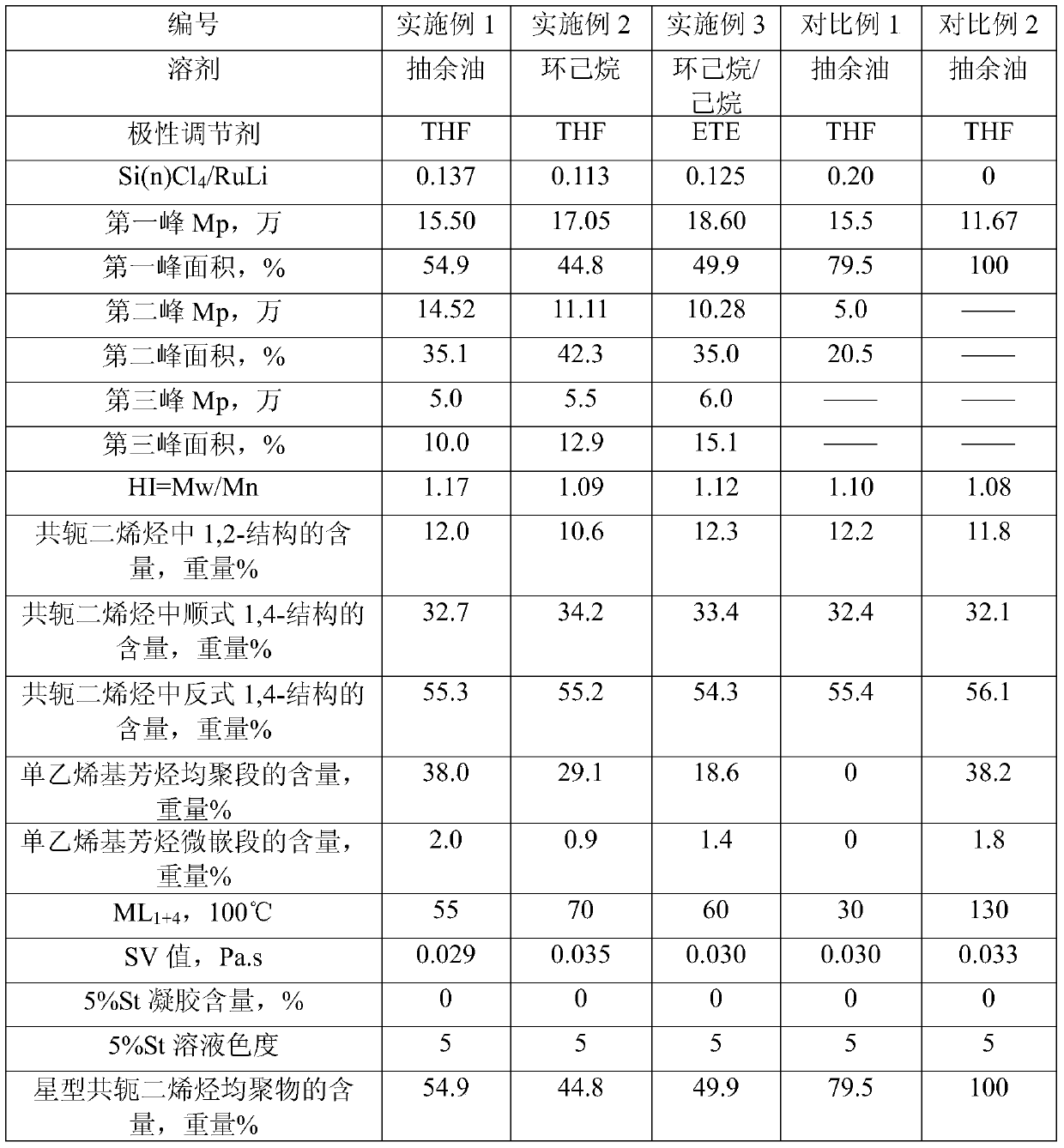

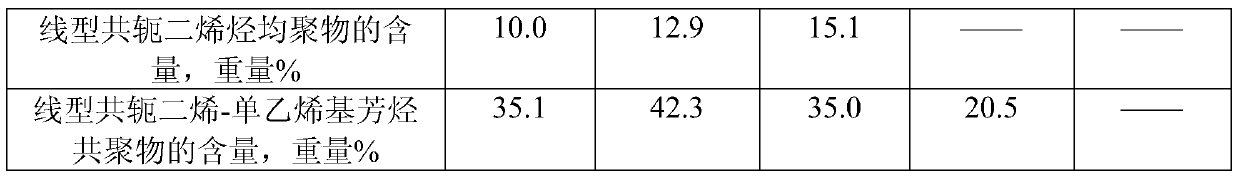

Embodiment 1

[0071] This example is used to illustrate the olefin polymer provided by the present invention and its preparation method.

[0072] The reaction apparatus used in this example includes a polymerization reactor. Under the protective atmosphere of high-purity nitrogen, add 2730g of raffinate oil, 559g of 1,3-butadiene, 0.395g of 1,2-butadiene, and 0.329g of tetrahydrofuran to a 5-liter polymerization kettle in sequence, start stirring, and Add 0.716g of n-butyllithium initiator at low temperature to carry out the first polymerization reaction, the reaction pressure is 0.1-0.3MPa, the reaction material starts to heat up, and reaches the highest reaction temperature of 90°C in 8 minutes of reaction, and the conversion of butadiene monomer is measured Rate reaches 97%; Add silicon tetrachloride (the total coupling group of silicon tetrachloride and the mol ratio of n-butyllithium is 0.55:1) coupling agent 0.261g in polymerization reactor again, and temperature control At 70°C, the...

Embodiment 2

[0074] This example is used to illustrate the olefin polymer provided by the present invention and its preparation method.

[0075] The reaction apparatus used in this example includes a polymerization reactor. Under the protective atmosphere of high-purity nitrogen, add 2,730g of cyclohexane, 444g of 1,3-butadiene, 0.381g of 1,2-butadiene, and 0.317g of tetrahydrofuran to a 5-liter polymerization kettle in sequence, and add them at a temperature of 53°C. 0.517g of n-butyllithium initiator is used for the first polymerization reaction, the reaction pressure is 0.1-0.3MPa, the reaction material starts to heat up, and reaches the highest reaction temperature of 85°C in 10 minutes of reaction, and the conversion rate of butadiene monomer is measured to reach 97%. Add silicon tetrachloride (the total coupling group of silicon tetrachloride and the mol ratio of n-butyllithium is 0.45:1) coupling agent 0.154g in polymerization kettle again, and temperature is controlled at 80 ℃, pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| coupling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com