Split type connecting rod

A split-type, connecting-rod technology, applied in textiles, textiles, papermaking, heddles, etc., can solve problems such as difficulty in widespread use, high production cost, and low production efficiency, achieve good promotion and utilization value, and increase tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

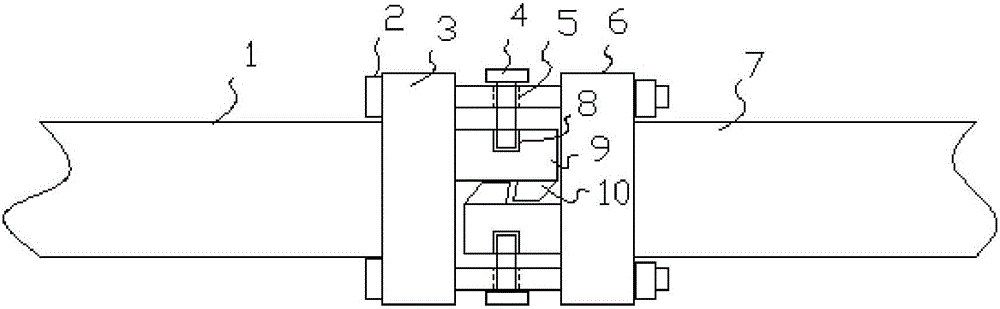

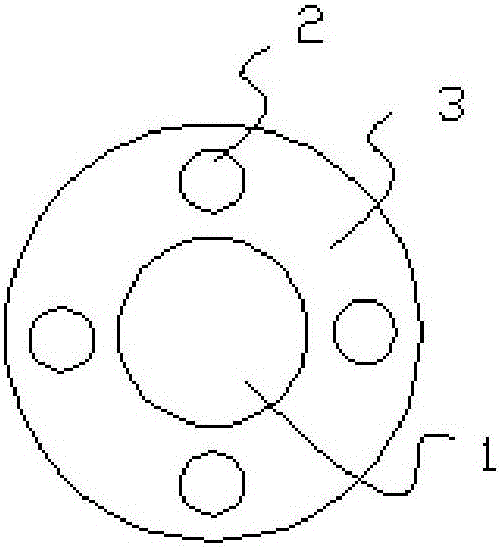

[0017] Such as figure 1 , figure 2 As shown, the structure of the split connecting rod includes a rod body 1 and a rod head 7. The connection surfaces of the rod body 1 and the rod head 7 are respectively provided with a first boss 3 and a second boss 6. The first Both the inner surfaces of the boss 3 and the second boss 6 are provided with connecting blocks 9 transversely, and the said connecting blocks 9 are provided with protrusions 10 hooked to each other. During use, the rod head and the rod body can play the role of initial connection through the mutual cooperation of the boss, the connecting block and the protrusion, and the connection mode of the hook can prevent slipping due to loose bolts in the later stage.

[0018] In the above embodiment, specifically, the first boss 3 and the second boss 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com