Method for preventing spontaneous combustion of coal seam of stopping line of strip mine

A technology for stopping production lines and open-pit mines, applied in dust prevention, mining equipment, earthwork drilling and mining, etc., can solve the problems of coal spontaneous combustion disasters, large engineering volume, high coverage thickness, etc., and achieve the effect of preventing coal spontaneous combustion disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

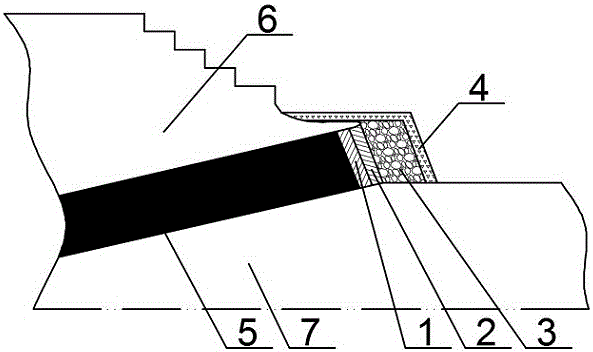

[0023] Below in conjunction with accompanying drawing, take the anti-spontaneous combustion treatment of the outcrop coal seam of Lingquan Open-pit Coal Mine in Zhalainuoer mining area as an example to further illustrate the present invention.

[0024] The Lingquan Open-pit Coal Mine of Zhalai Nuoer Coal Industry Co., Ltd. was closed in early 2015 according to the plan, and then the mining area was reclaimed and ecologically restored, and a geological park was planned to be built.

[0025] The east side of the mine is its coal mining work side. After the pit is closed, this method is adopted to treat the outcropping coal seam of the side stop mining line, which effectively prevents spontaneous combustion of the coal seam at this place.

[0026] Such as figure 1 As shown, the specific implementation steps of the method for preventing the spontaneous combustion of the outcrop coal seam of the stop production line are as follows:

[0027] (1) Level or slope the coal body at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com