High-pressure hydrothermal solution inhibition method for coal seam

A hydrothermal and high-pressure technology, applied in earthwork drilling, safety devices, mining equipment, etc., can solve the problem that the inhibitory effect of the inhibitor cannot be fully exerted, the chemical reaction is limited, and the active groups on the coal surface cannot be effectively eliminated, etc. problems, to achieve the effects of preventing coal spontaneous combustion disasters, reducing the quantity, wide practicability and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

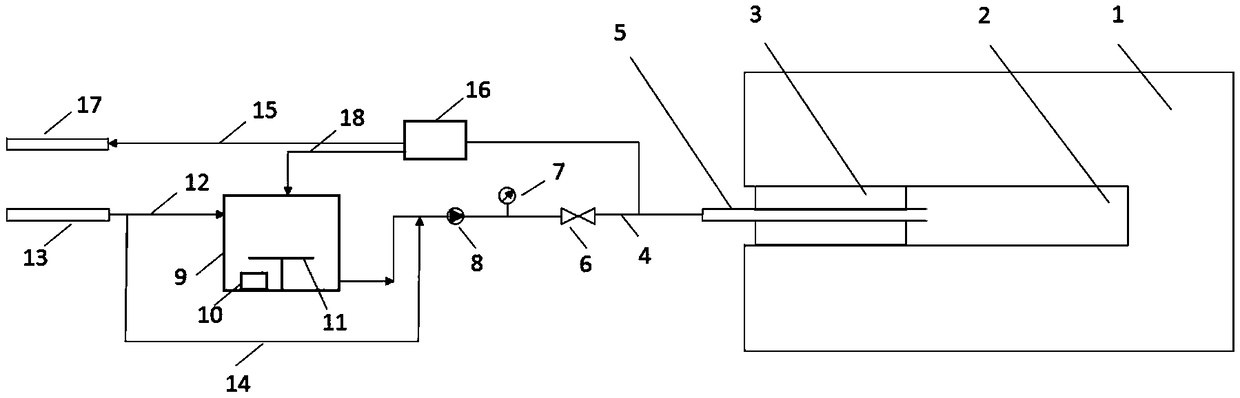

[0032] Coal seam high pressure hydrothermal resistance method, the specific steps are:

[0033] First, construct a layered hole 2 with a diameter of 113mm and a length of 120m in the coal seam, and then seal the layered hole 2 with a hole sealer with a length of 10m and a resistance of 12MPa. Then, the intermediate steel pipe 5, the flow valve 6, the pressure gauge 7, the high pressure pump 8, and the solution tank 9 of the hole sealer 3 are sequentially connected with a rubber hose resistant to 120° C. and 12 MPa, and the first steel pipe 12 is used to connect the underground water supply pipe 13 and the solution tank. 9. The second steel pipe 14 is used to connect the underground water supply pipe 13 and the high-pressure pump 8, the third steel pipe 15 is used to connect the intermediate steel pipe 5 of the hole sealer 3, the pumping pump 16 and the underground drainage pipe 17 in turn, and the fourth steel pipe 18 is used to connect the pumping pipe. Liquid pump 16 and sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com