Method for operating a fuel injector

A technique for jet valves and operating characteristics, applied in the field of operating jet valves, to achieve the effect of short interval time and low precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

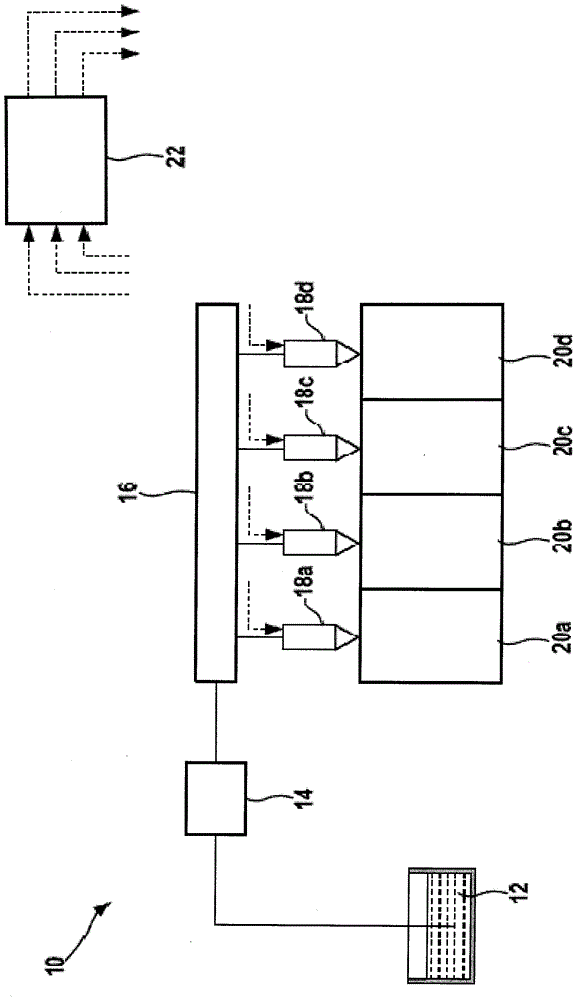

[0023] internal combustion engine in figure 1 The center bears the reference numeral 10 as a whole. It includes a fuel tank 12 from which a delivery system 14 delivers fuel into a common rail 16 . A plurality of electromagnetically actuated injection valves 18a to 18d are connected to this common rail, which inject fuel directly into the combustion chambers 20a to 20d assigned to them. The operation of internal combustion engine 10 is controlled or regulated by a control and regulating device 22 which, in particular, also actuates injection valves 18a to 18d.

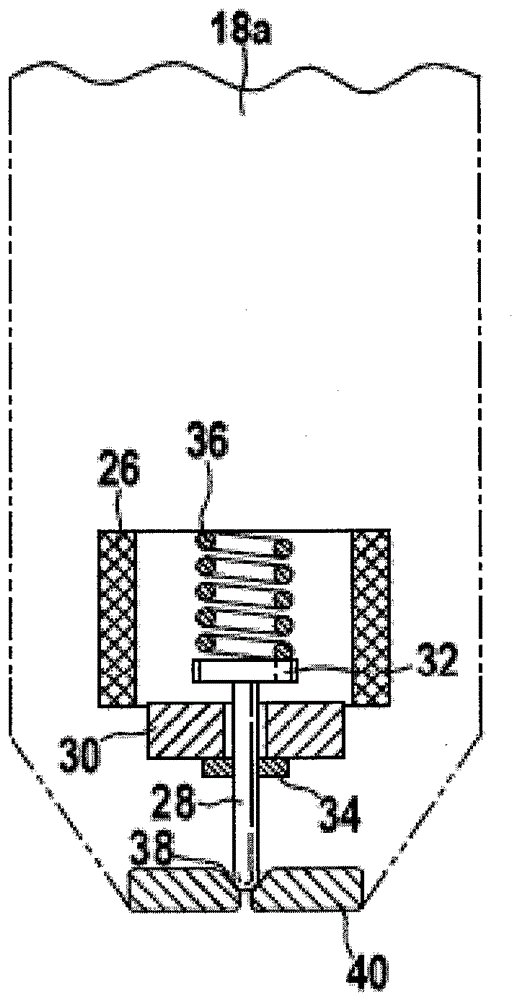

[0024] Figures 2a to 2c schematically illustrate the following figure 1 Injection valve 18a in a total of three different operating states. other in figure 1 The injection valves 18b, 18c, 18d depicted in have a corresponding structure and function.

[0025] Injection valve 18 a has an electromagnetic actuator having a solenoid coil 26 and an armature 30 interacting with solenoid coil 26 . The armature 30 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com