Automatic production equipment for rubber products

An automatic production and rubber technology, which is applied in the field of mechanical manufacturing automation, can solve problems such as lack of connection, achieve orderly and smooth connection, improve work efficiency, and save manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment,

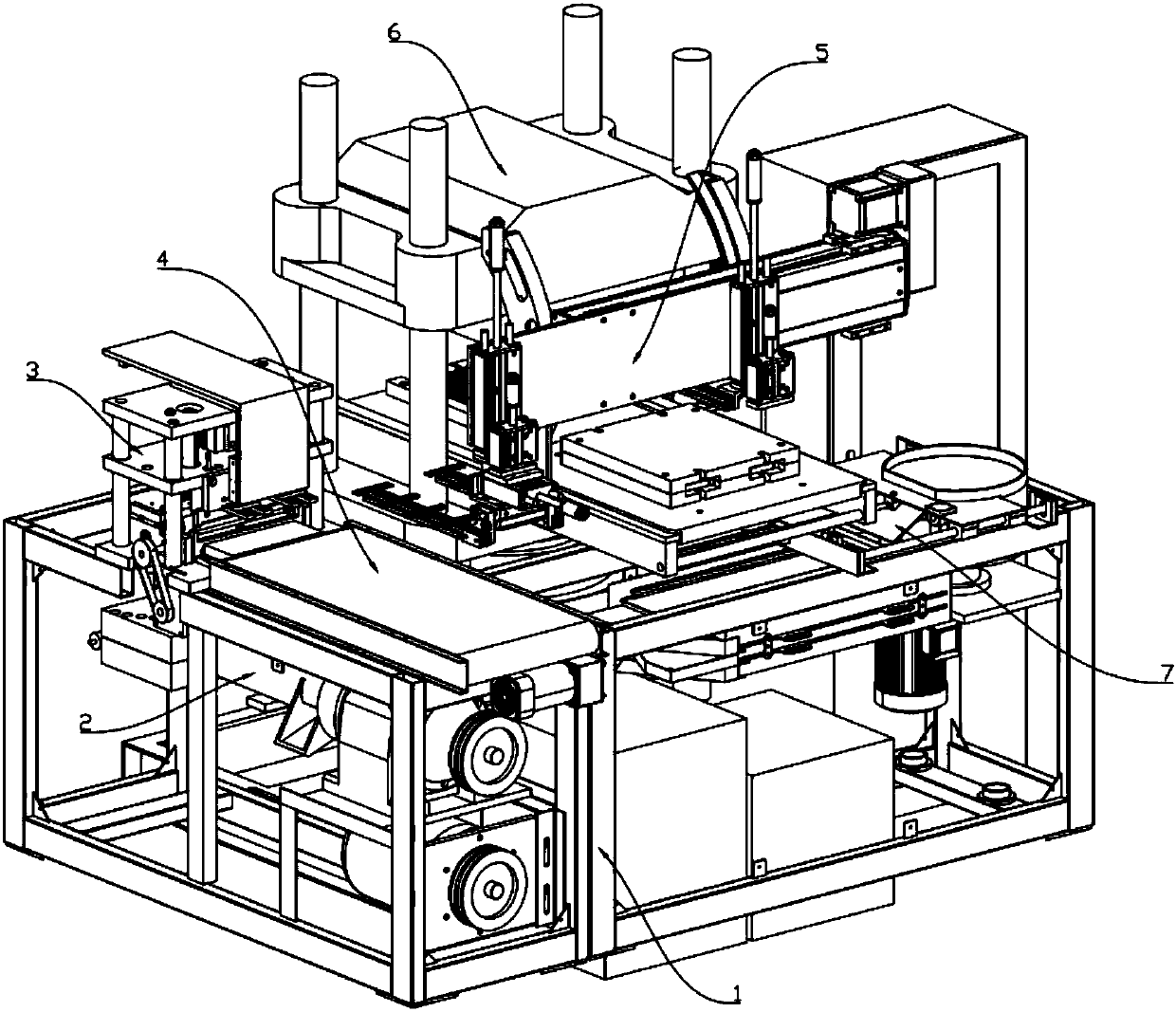

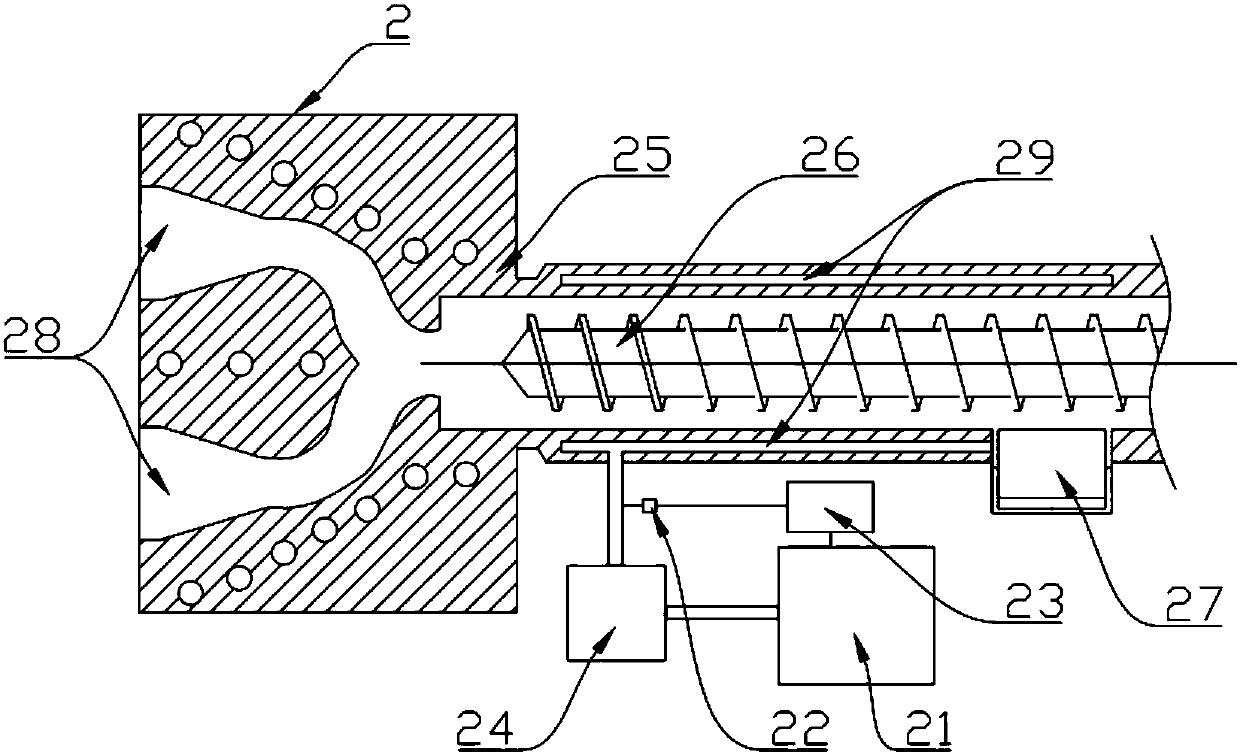

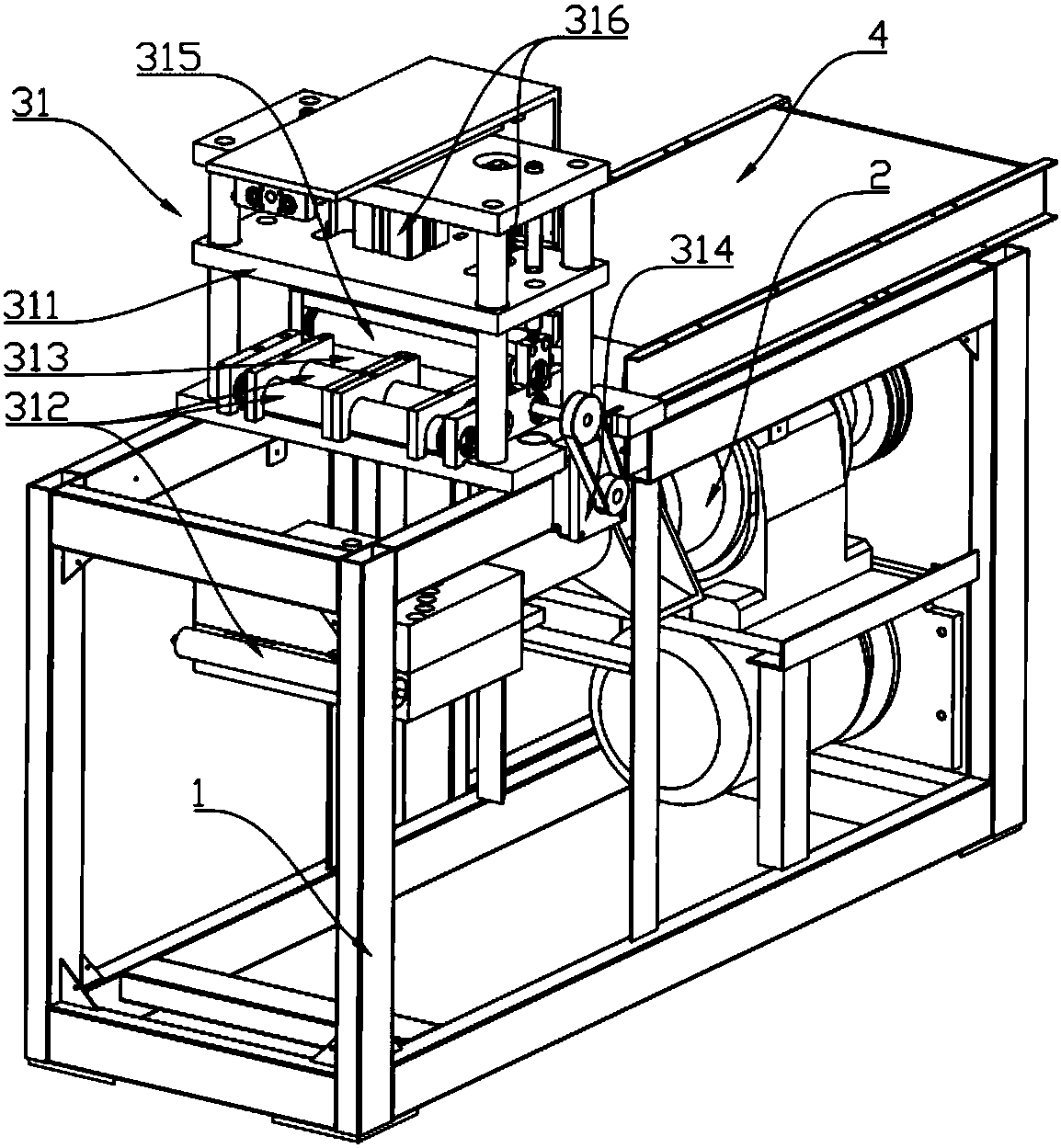

[0043] Such as figure 1As shown, the technical solution of the present invention specifically refers to an automatic production equipment that can reduce the workload of operators and can effectively improve the production efficiency and quality of rubber products. For operators, the only role they need to play is to control The normal operation of the machine is sufficient. When using this equipment to process rubber products, the operator puts the rubber material into the rubber extruder 2, and the equipment starts automatic operation. The rubber material enters the rubber extruder 2 and is extruded from the discharge port 28 to form a rubber belt. , the rubber belt is driven forward by the transfer cutting device 3, and is calendered in the transfer cutting device 3, and the transfer cutting device 3 cuts the calendered rubber belt into a secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com