Floor tile pavement positioning measurement device

A technology of positioning measurement and floor tiles, which is applied in the field of architectural decoration devices, can solve the problems of slow construction speed, low efficiency, and uneven width of mortar joints, and achieve the effects of fast construction speed, high efficiency and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

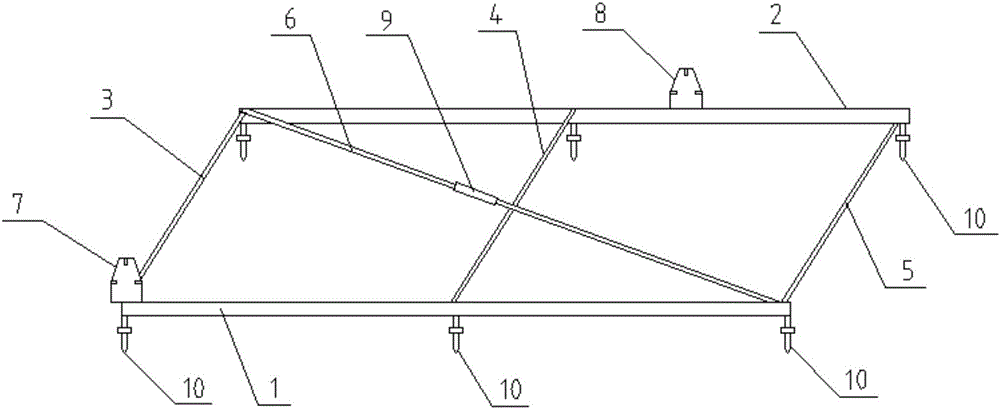

[0012] As shown in the drawings, a floor tile laying positioning measurement device in this embodiment includes a front thickness adjustment backing board 1, a rear thickness adjustment backing board 2, a left balance longitudinal rod 3, a middle balance longitudinal rod 4, a right balance longitudinal rod The balance frame composed of bar 5 and diagonal balance bar 6, horizontal gray seam infrared controller 7, longitudinal gray seam infrared controller 8, striker balance degree measuring device 9 and six height-adjustable support nuts 10, the front thickness The adjustment leaner 1, the left balance longitudinal rod 3, the rear thickness adjustment leaner 2 and the right balance longitudinal rod 5 are sequentially connected to a rectangular frame, and the front thickness adjustment leaner 1, the left balance longitudinal rod 3, and the rear thickness adjustment leaner 2 And the right balance longitudinal rod 5 is provided with a length scale, in order to measure the size of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com