Method for conducting dry-wet cycle and direct shear test on simulated load-bearing soil

A dry-wet cycle and simulated soil technology, applied in the direction of applying stable shear force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of affecting the experimental results, slow dry-wet cycle process, and large disturbance of the sample , to achieve the effect of easy engineering application, simple and cheap material, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

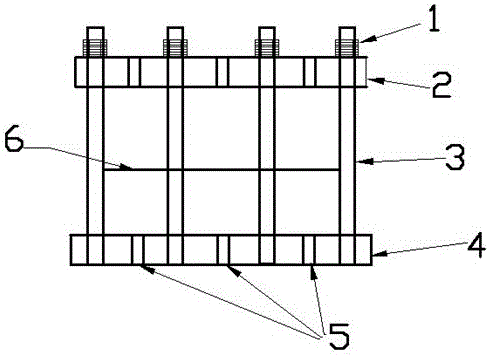

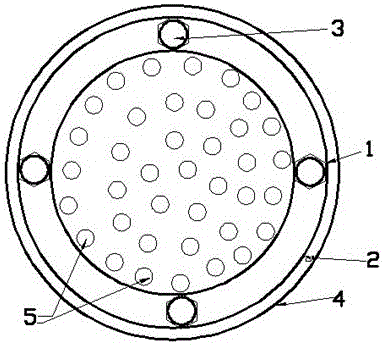

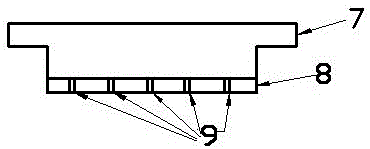

[0030] (1) Set up a device for dry-wet cycle and direct shear test under the condition of simulating soil load, which is composed of dry-wet cycle device and shear box. The dry-wet cycle device includes nut 1, fixed ring 2, vertical rod 3 , lower bottom plate 4, lower bottom plate drainage hole 5, ring knife 6, ring knife buckle 13, cross edge 7, upper cover plate 8 and upper cover plate drainage hole 9; ring knife 6 is divided into upper and lower halves on average, and the lower half The bottom is threaded, and the upper and lower halves of the ring cutter 6 can be fixed as a whole with the ring cutter buckle 13; The bottom thread is screwed together; the vertical rod 3 is fixedly connected with the lower base plate 4 and the entire length of the vertical rod 3 is threaded; the upper cover plate 8 is provided with a cross rib 7 and an upper cover drain hole, and the upper end of the cross rib is larger than the fixed ring 2. The outer diameter is 1 cm larger; the diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com