Method and equipment for battery powder ring filling

A battery steel shell and powder ring technology, applied to dry batteries, etc., can solve the problems of manual inspection of the powder ring in the battery steel shell, the difficulty of three powder rings in the battery steel shell, and the flow of unqualified products into the market, so as to avoid defective products The effect of entering the market, realizing automatic and accurate detection, improving efficiency and utilization of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

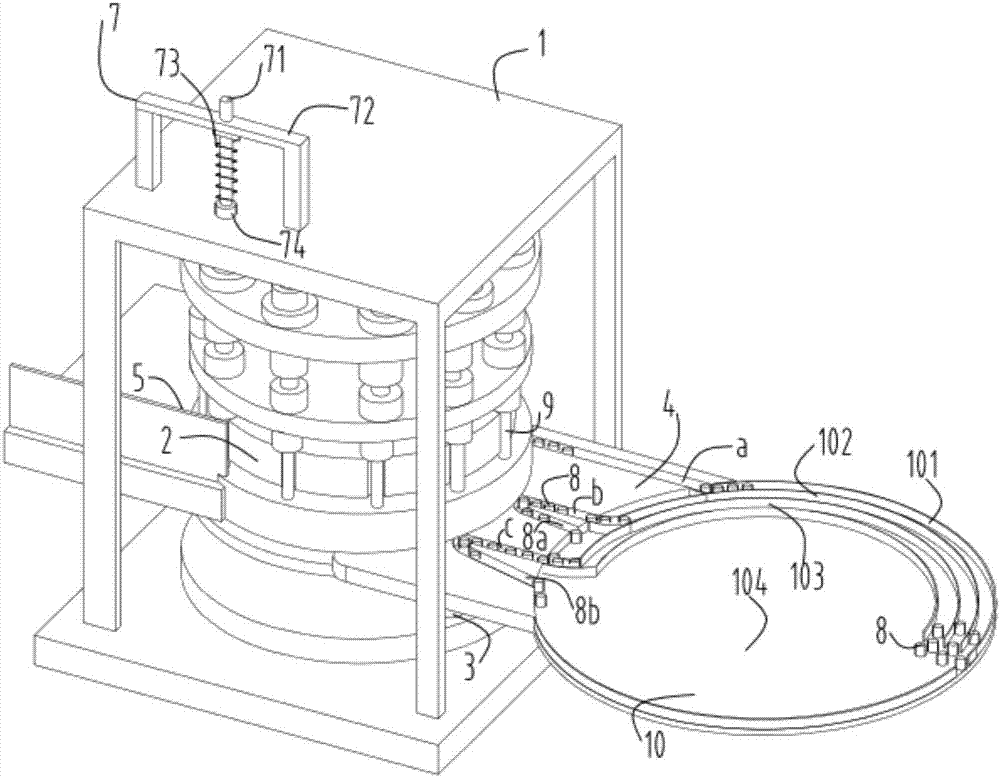

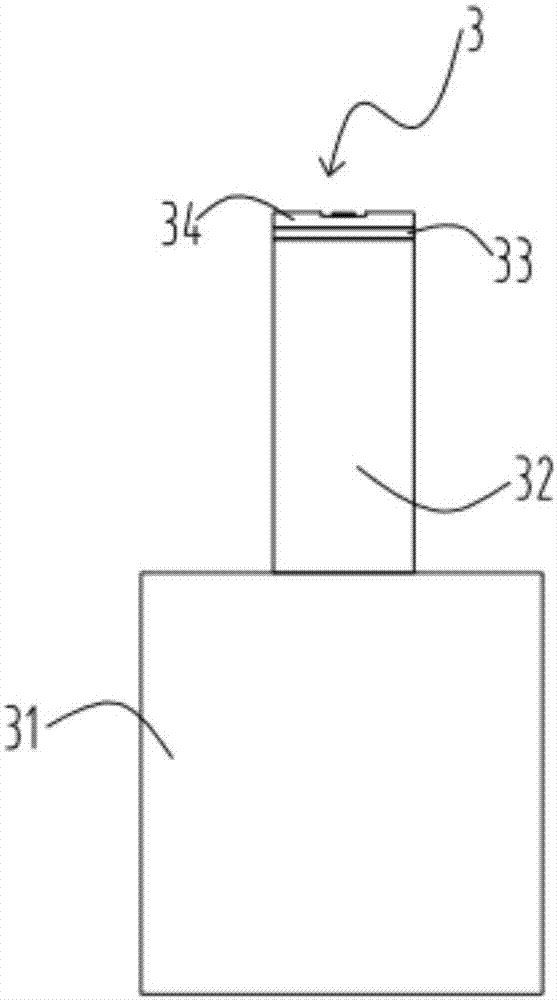

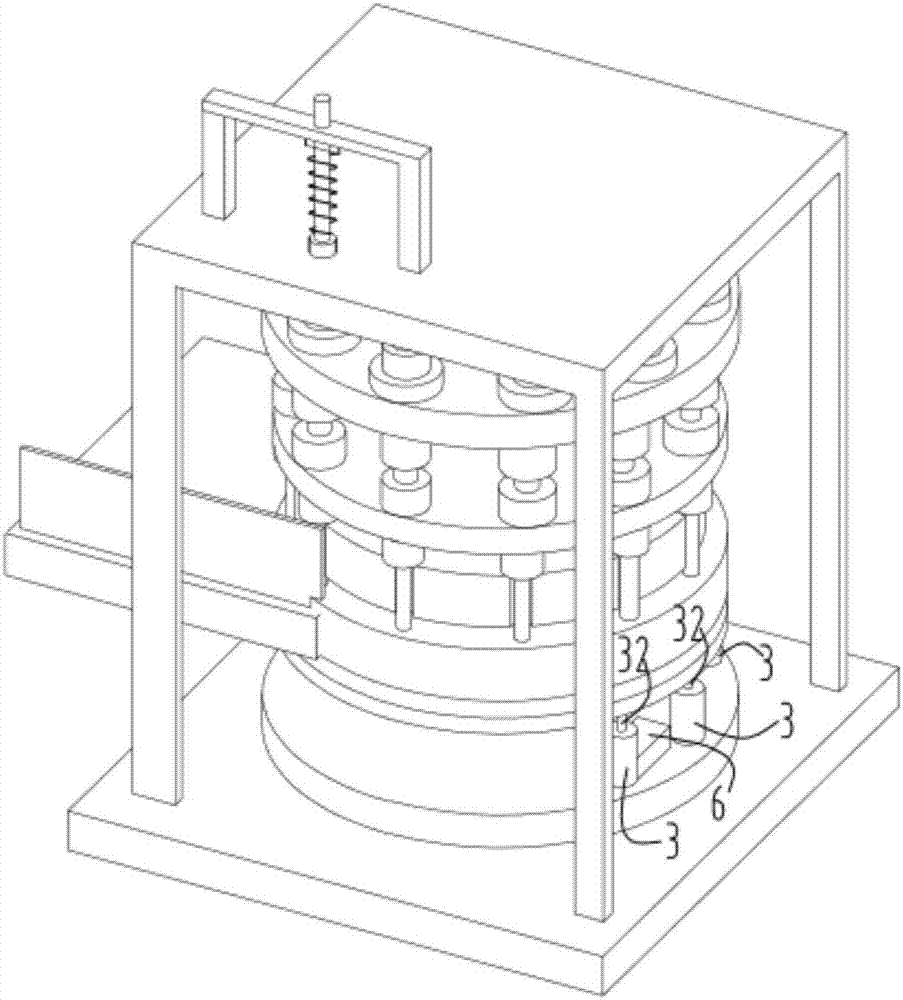

[0044] figure 1 Schematic diagram of the powder ring into the shell equipment, figure 2 Enlarged schematic diagram for the jacking mechanism, image 3 It is a partial perspective schematic diagram of the powder ring into the shell equipment, Figure 4 Schematic diagram of the work of the distribution tray and the powder ring conveyor table, Figure 5 Schematic diagram for opening the active baffle of the discharge device, Image 6 Schematic diagram for the closing of the active baffle of the discharge device. like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, what is provided in this embodiment is a method for inserting battery powder into the shell, including the following steps:

[0045] a. Lead the battery steel case 9 into the continuously rotating shell feeding turntable 2;

[0046] b. The powder ring 8 is sent from the first feeding chute a, the second feeding chute b and the third feeding chute c to the three different shell ...

Embodiment 2

[0052] figure 1 Schematic diagram of the powder ring into the shell equipment, figure 2 Enlarged schematic diagram for the jacking mechanism, image 3 It is a partial perspective schematic diagram of the powder ring into the shell equipment, Figure 4 Schematic diagram of the work of the distribution tray and the powder ring conveyor table, Figure 5 Schematic diagram for opening the active baffle of the discharge device, Image 6 Schematic diagram for the closing of the active baffle of the discharge device. like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, what is provided in this embodiment is a kind of equipment for implementing the battery powder ring into the shell method, including a frame 1, a shell feeding turntable 2, a feeding mechanism 3, a powder ring conveying platform 4, and a discharge device 5. The electric control device 6 and the electric control unit 70, the shell feeding turntable 2 is connected to the frame 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com