Bitterness removing method of citrus juice

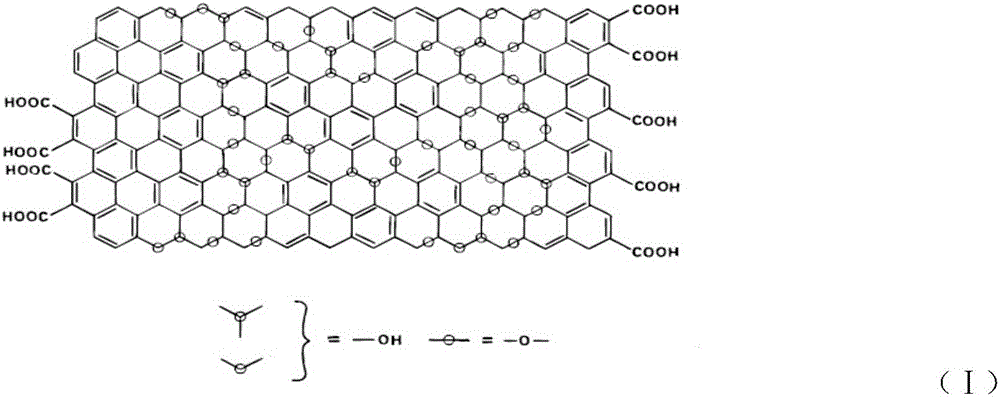

A citrus juice and debittering technology, applied in food science and other directions, can solve the problems of low reuse rate, high cost, poor specificity, etc., and achieve the effects of high reuse rate, quality improvement, and strong adsorption specificity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

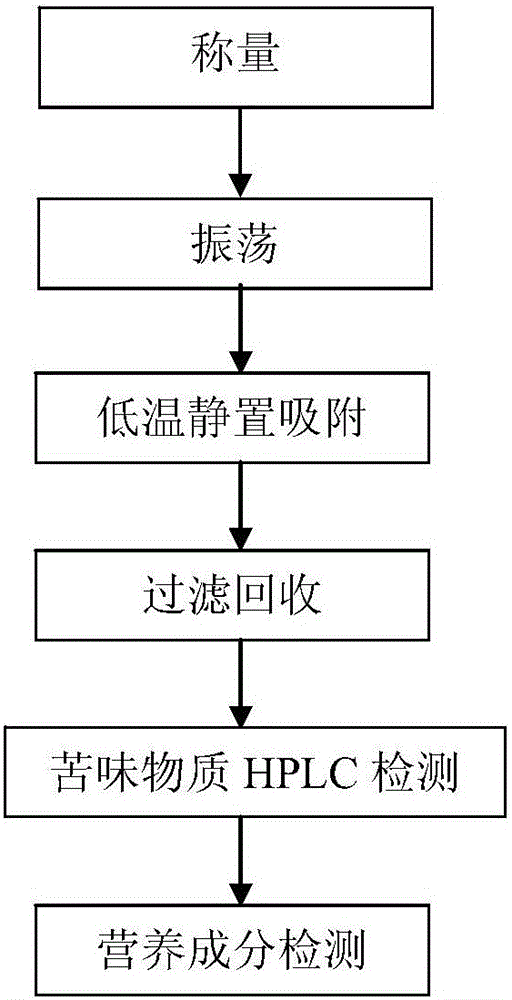

[0025] A kind of debittering method of citrus juice of the present invention, technological process is as figure 1 Shown (omit sensory evaluation), comprise the following steps:

[0026] (1) Weighing: 0.1 g of graphene oxide powder (commercially available) was weighed, and 1 L of citrus juice was weighed, specifically, sweet orange juice.

[0027] (2) Oscillation: Add the graphene oxide powder in step (1) directly into the citrus juice, oscillate at a constant temperature at 20°C for 2 hours, and the oscillation frequency is 180r / min.

[0028] (3) Adsorption: After the oscillation, the oscillation liquid obtained in step (2) was placed in a refrigerator at 4° C. for 6.0 h to allow the graphene oxide to adsorb the bitter components in the citrus juice to obtain an adsorption liquid.

[0029] (4) Filtration: The adsorption liquid obtained in step (3) is subjected to refrigerated centrifugation and filtration, the centrifugal speed is 8000r / min, and the refrigerated centrifugati...

Embodiment 2

[0041] A method for debittering citrus juice of the present invention, comprising the following steps:

[0042] (1) Weighing: Weigh 0.1 g of graphene oxide powder, and weigh 1 L of citrus juice, specifically Newhall navel orange juice.

[0043] (2) Oscillation: Add the graphene oxide powder in step (1) directly into the citrus juice, oscillate at a constant temperature at 20°C for 2 hours, and the oscillation frequency is 180r / min.

[0044] (3) Adsorption: After the oscillation, the oscillation liquid obtained in step (2) was placed in a refrigerator at 4° C. for 6.0 h to obtain the absorption liquid.

[0045] (4) Filtration: The adsorption solution obtained in step (3) is subjected to refrigerated centrifugal filtration at a rotating speed of 8000r / min, and the refrigerated centrifugation time is 20min, so as to completely separate graphene oxide. After filtration, debittered citrus juice was obtained, and graphene oxide was recovered.

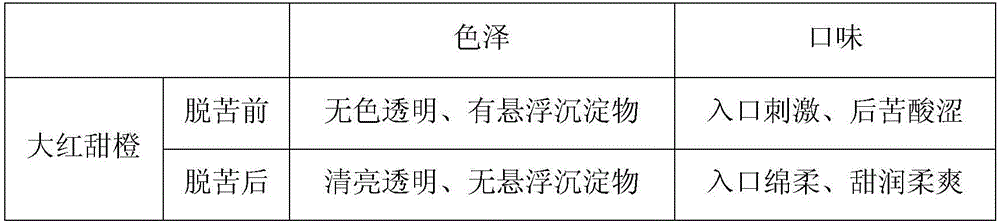

[0046] (5) For the citrus juice befo...

Embodiment 3

[0057] The debittering method of the citrus juice of the present embodiment is basically the same as that of Example 1, except that the ratio of the mass of graphene oxide to the volume of the citrus juice is 0.3g: 1L, and the selected citrus is sour orange. Under this condition, the main bitter substances and nutrients in lime juice and the conclusions of the debittering rate are as follows:

[0058] Table 7 Changes in content of main bitter substances in citrus juice before and after debittering and calculation of debittering rate

[0059]

[0060] Table 8 Changes in nutrient content of citrus juice before and after debittering and calculation of loss rate

[0061]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap