Bimetal composite N-amyl imidazole thiocyanate ionic liquid as well as preparation method and application thereof in CO treatment

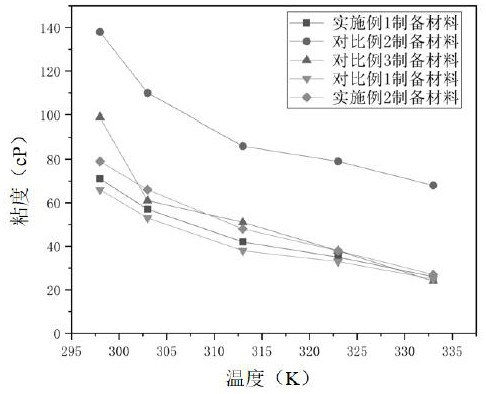

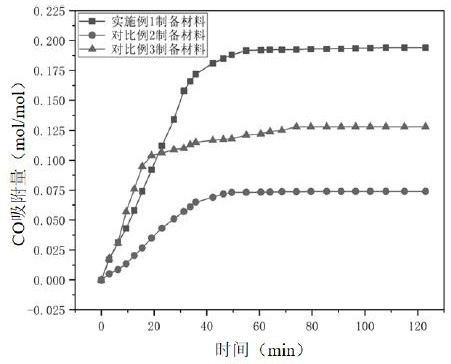

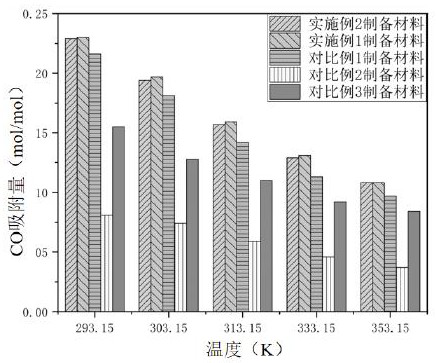

A technology of amyl imidazolium thiocyanate and ionic liquid, which is applied in the field of new waste gas treatment materials, can solve the problems that the absorption capacity is greatly affected by temperature, the viscosity of ionic liquid is large, and the cycle stability is poor, so as to achieve good cycle adsorption performance and adsorption No change in performance, the effect of optimizing the absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment prepares a kind of bimetallic composite N-amyl imidazole thiocyanate ionic liquid, wherein the molar ratio of N-amyl imidazole thiocyanate, cuprous thiocyanate, magnesium thiocyanate in the ionic liquid is 1 :1:1, the synthetic route map is as follows figure 1 As shown, it specifically includes the following steps:

[0039] (1) Synthesis of N-amyl imidazolium thiocyanate ionic liquid:

[0040] Using acetone as solvent, add N-pentylimidazole hydrochloride (17.4 g, 0.1 mol) and sodium thiocyanate (8.1 g, 0.1 mol) into the flask, stir at room temperature for 24 h, rotary evaporate, and extract and separate with chloroform To obtain an ionic liquid, the obtained ionic liquid was washed several times with deionized water until AgNO was added to the washed water 3 After that, no precipitation occurred, and finally rotary evaporation was performed, and vacuum drying was performed at 80°C for 6 h to obtain 16.8 g of N-pentylimidazolium thiocyanate ionic liquid...

Embodiment 2

[0044] This embodiment prepares a kind of bimetallic composite N-amyl imidazole thiocyanate ionic liquid, wherein the molar ratio of N-amyl imidazole thiocyanate, cuprous thiocyanate, magnesium thiocyanate in the ionic liquid is 1 :1.5:1.5, the synthetic route is as follows figure 1 As shown, it specifically includes the following steps:

[0045] (1) Synthesis of N-amyl imidazolium thiocyanate ionic liquid:

[0046] Using acetone as solvent, add N-pentylimidazole hydrochloride (17.4 g, 0.1 mol) and sodium thiocyanate (8.1 g, 0.1 mol) into the flask, stir at room temperature for 24 h, rotary evaporate, and extract and separate with chloroform To obtain an ionic liquid, the obtained ionic liquid was washed several times with deionized water until AgNO was added to the washed water 3 After that, no precipitation occurred, and finally rotary evaporation was carried out, and vacuum drying was carried out at 80°C for 6 h to obtain 16.8 g of N-pentylimidazolium thiocyanate ionic li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com