Anchor net hooking wrench

A technology of anchor netting and connecting wrench, which is applied in the direction of wrench, manufacturing tools, wrench, etc., can solve the problems of secondary loosening of the head-on roof, increase support cost, and reduce labor efficiency, so as to improve production efficiency and increase support cost , the effect of reducing labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to further understand the content, characteristics and effects of the patent of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

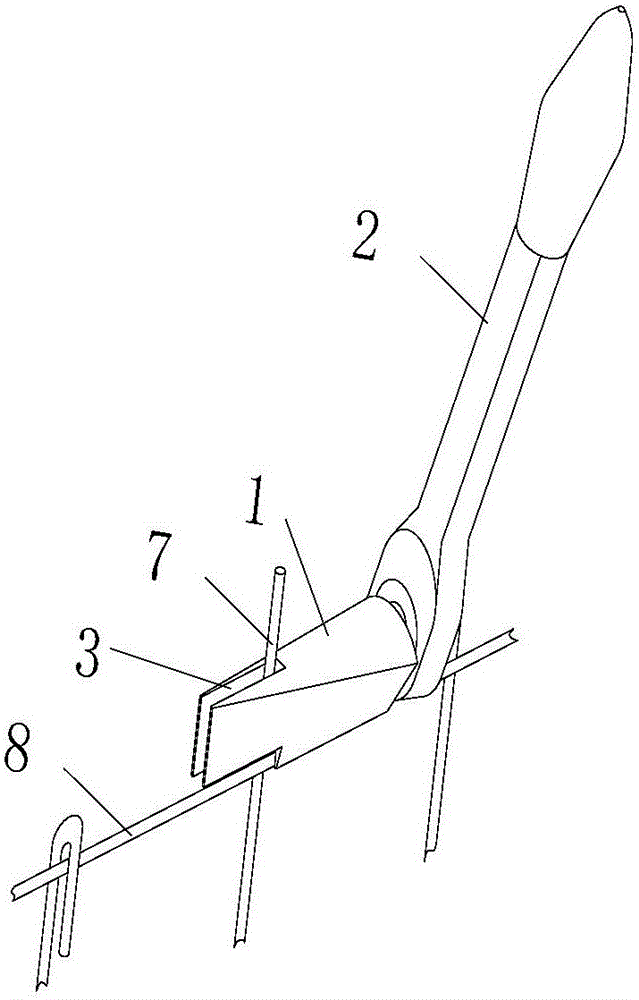

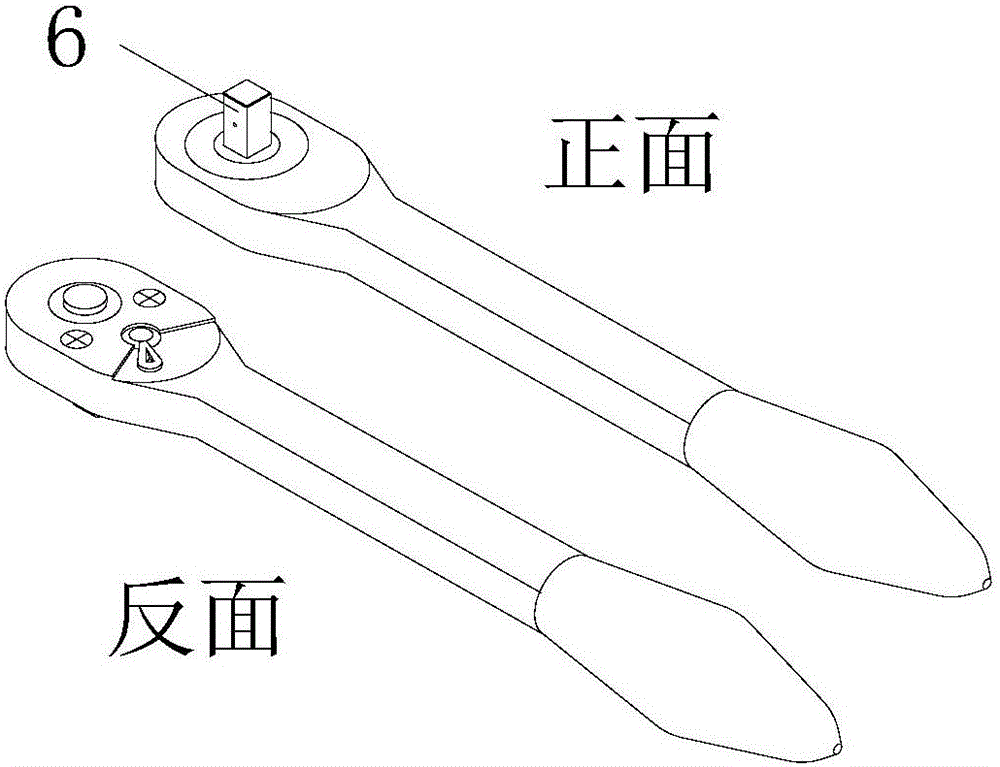

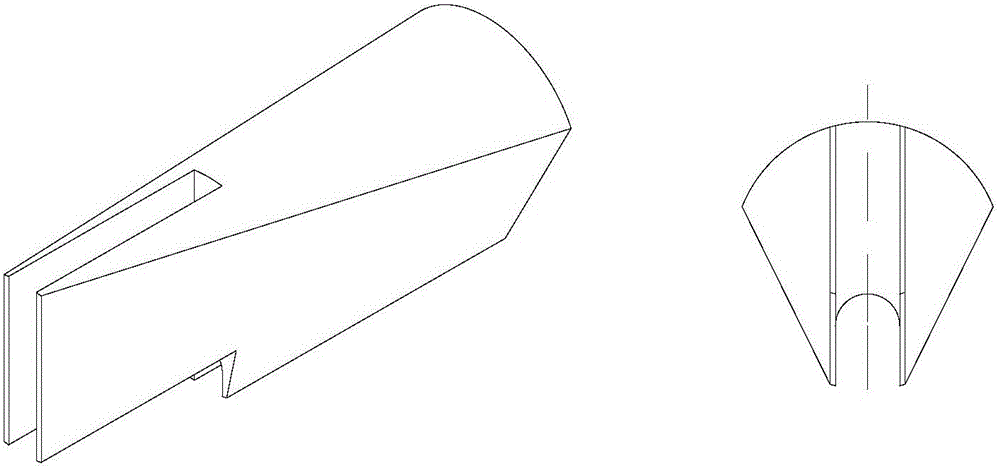

[0010] The invention relates to an anchor net hooking wrench, which is composed of a plug and a quick-release ratchet wrench. The plug is composed of a longitudinal rib slot, a transverse rib slot, and a U-shaped socket. The present invention selects the common quick-release ratchet wrench on the market as the force arm, which is convenient for matching and assembling and disassembling the anchor net hooking wrench. The invention perfectly solves the need to unload the head bolts between the anchor mesh stubble between cycles, resulting in secondary loosening of the head roof; the metal mesh network uses iron wires, which wastes manpower and material resources, increases support costs, and reduces labor efficiency; When lapp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com