Plastic extruder

A technology for plastic extruders and outlets, which is applied in the field of plastic extruders and can solve problems such as unsustainable discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

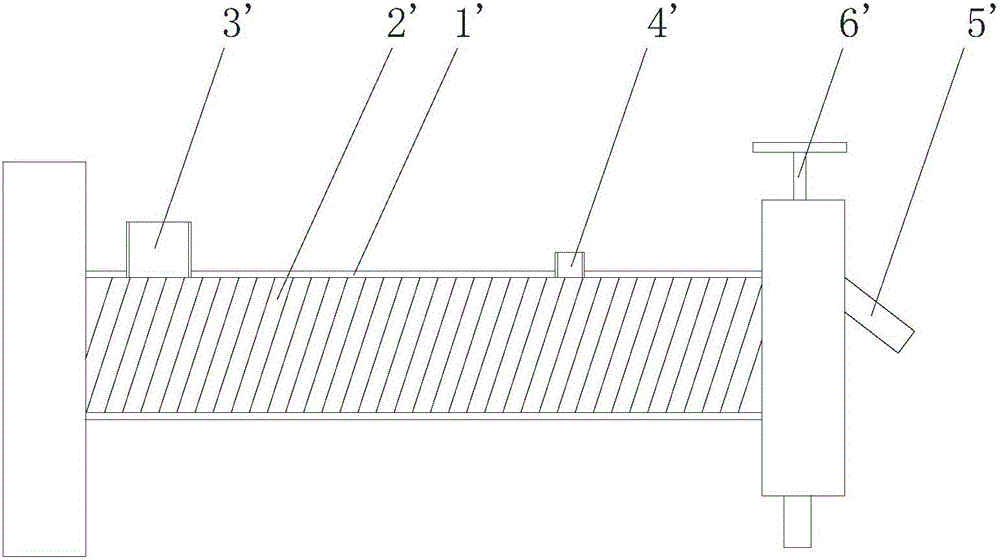

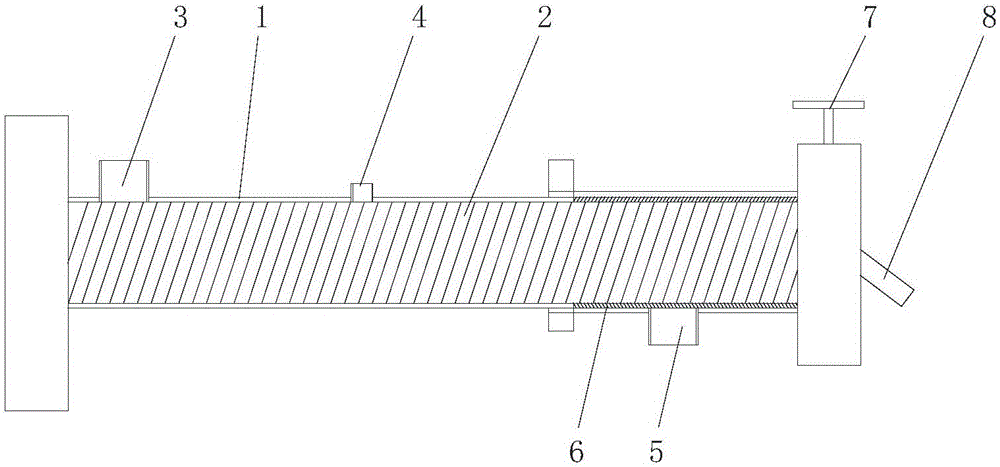

[0027] Such as figure 2 As shown, a plastic extruder provided by the embodiment of the present invention includes a barrel 1 and a screw 2 built in the barrel 1, an extrusion channel is formed between the outer wall of the screw 2 and the inner wall of the barrel 1, and the barrel 1 is provided with a feed port 3, an exhaust port 4, a discharge port and a sewage discharge port 8 in sequence along the extrusion channel, and also includes a filter 6, which is connected to the joint between the discharge port and the extrusion channel.

[0028] Specifically, other structures of the feed port 3, the screw 2, and the plastic extruder, such as the drive mechanism, transmission structure, etc., can refer to related prior art. The main improvement of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com