Pushing and pressing vegetable cutting machine

A vegetable cutter and push plate technology, which is applied in metal processing, food processing, application, etc., can solve the problems of large size of vegetable cutters, and achieve the effect of convenient use and reduced space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

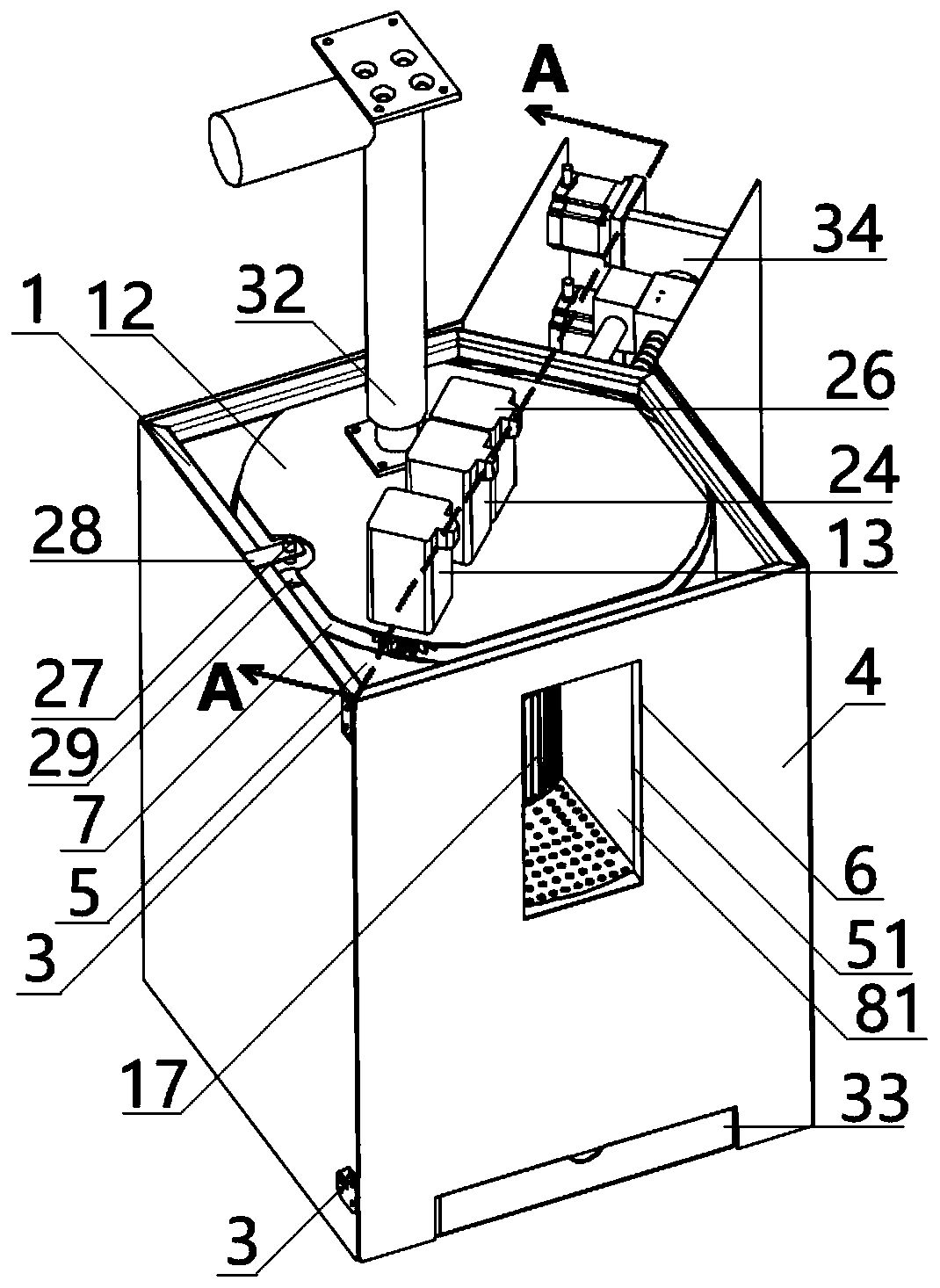

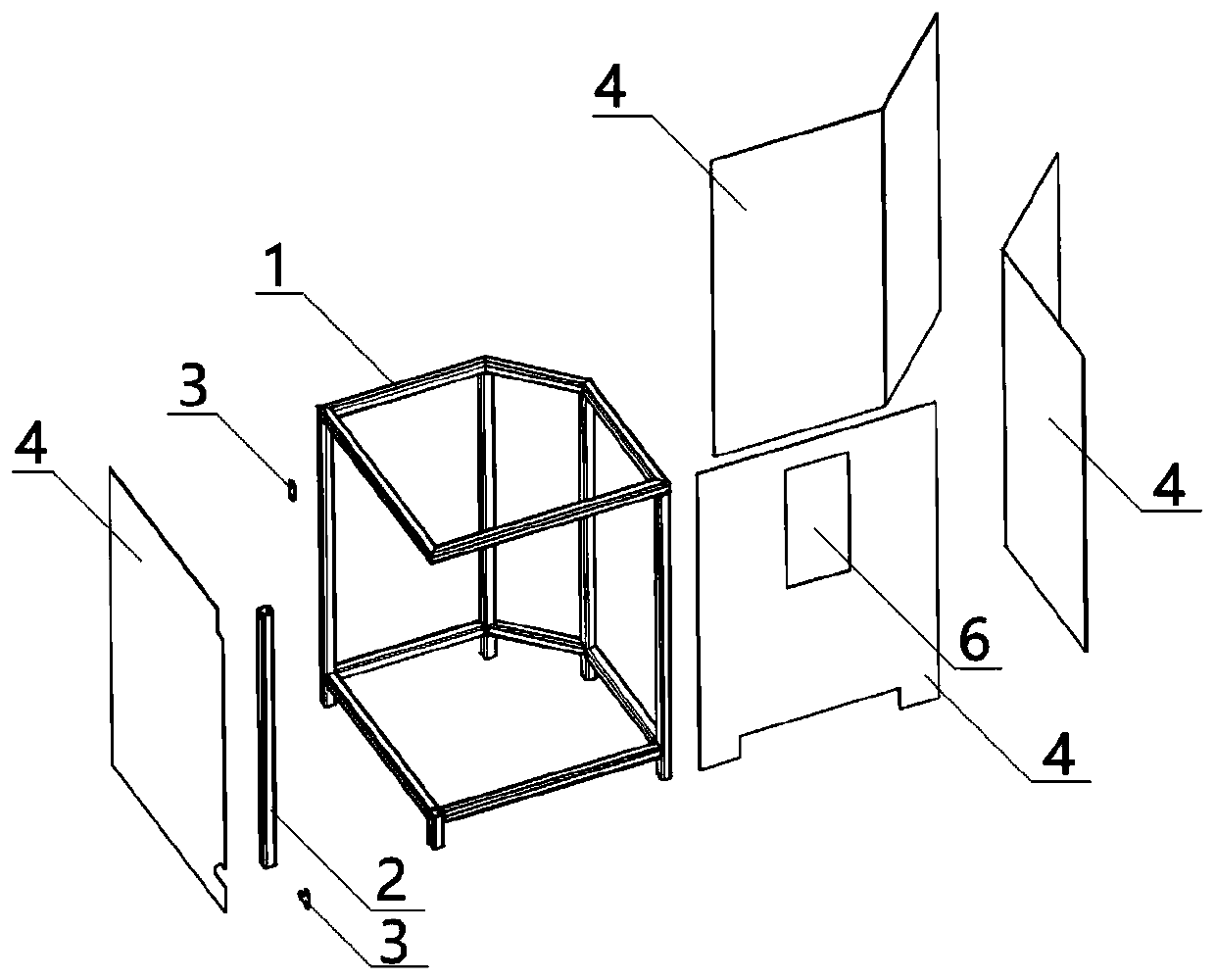

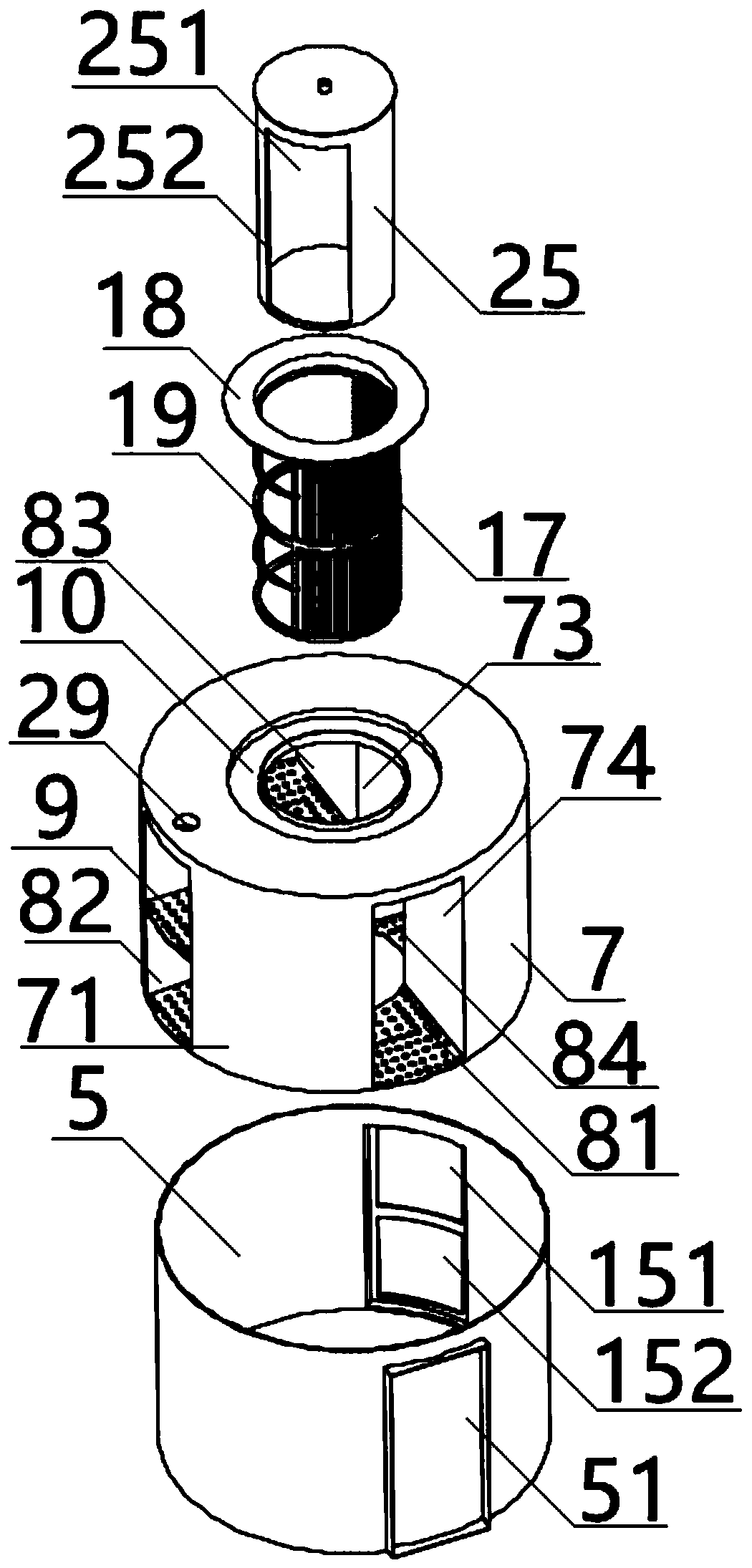

[0019] like figure 1 As shown, a kind of pushing vegetable cutting machine of the present invention has the motor mounting plate 12 that is positioned at the top, and the first motor 13, the second motor 24, the 3rd motor 26 are installed on the motor mounting plate 12, as image 3 As shown, the bottom of the motor mounting plate 12 is sequentially provided with a vegetable dish 7, a first-layer grid knife 17 and a second-layer rotary knife 25 from the outside to the inside, as shown in FIG. Figure 5 As shown, the first motor 13, the second motor 24, and the third motor 26 are respectively connected to the serving tray 7, the first layer of grid knife 17 and the second layer of rotary knife 25, so that the first motor 13, the second motor 24, the third The motor 26 corresponds to drive the serving tray 7, the grid knife 17 of the first layer and the rotary knife 25 of the second layer to rotate independently.

[0020] like Figure 4 As shown, the serving tray 7 is annular, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com