A helicopter rotor anti-icing/deicing method using spraying nozzles to spray icing condensation nuclei and deicing fluid

A technology for helicopter rotors and jet heads, which is used in deicing devices, aircraft parts, transportation and packaging, etc., can solve the problems of less anti-icing/deicing technology, and achieve the effects of less pollution, improved utilization, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

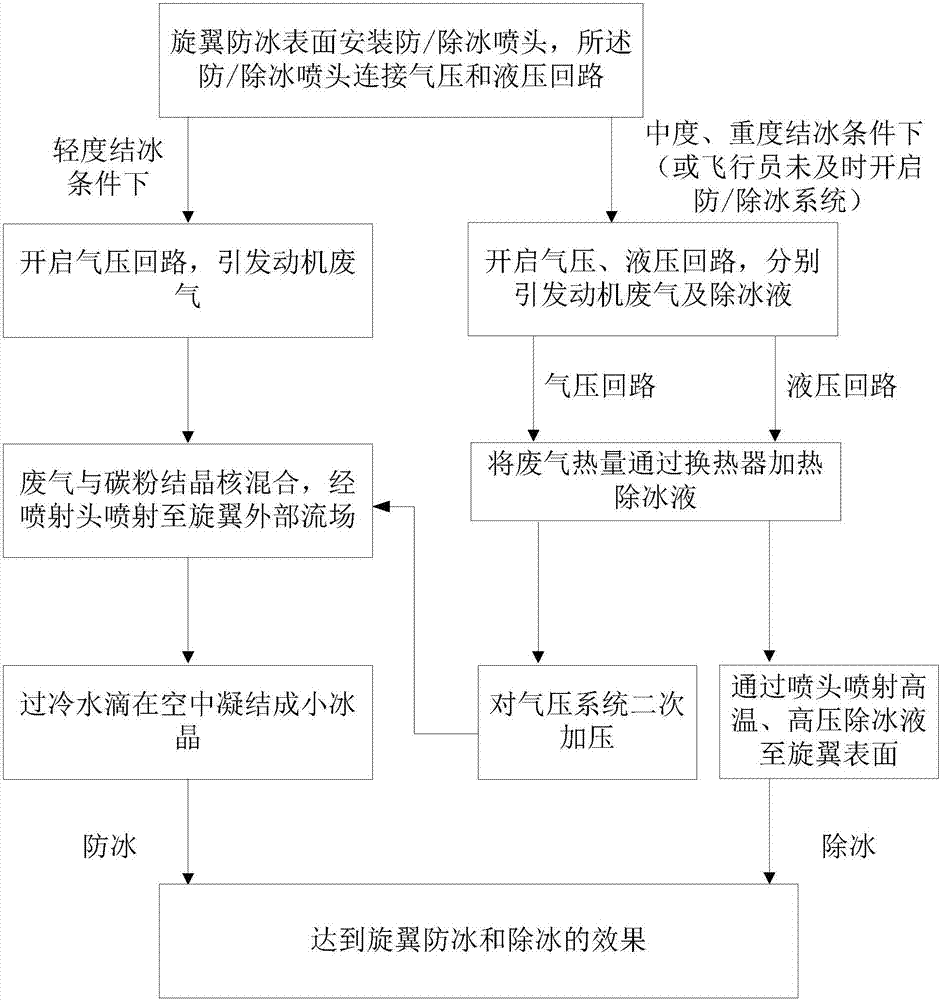

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

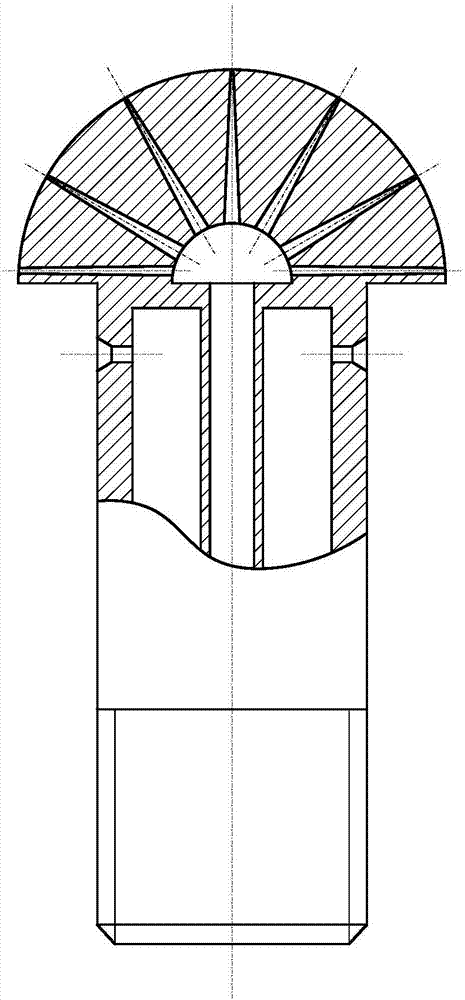

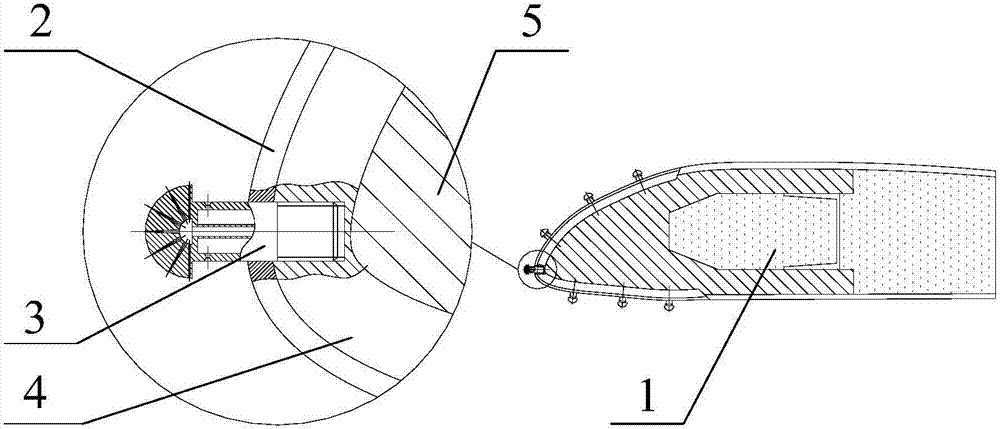

[0028] Such as figure 1 The structure of the anti-icing / de-icing nozzle shown is an air-liquid two-way nozzle. The upper part of the nozzle is a hemispherical structure, and the lower part is a casing structure; the hemispherical structure can spray high-pressure engine exhaust gas mixed with carbon powder, and the casing structure has nozzles to spray the engine. For the deicing fluid heated by exhaust gas, in order to ensure the injection range, the cross-sectional size of the gas channel inside the hemispherical structure is designed to gradually decrease from the inside to the outside, thereby increasing the speed at the nozzle on the surface of the hemisphere and increasing the spraying range; anti-icing nozzle casing In the structure, the inner pipe and the outer pipe are equipped with external threads for connecting pipelines, which is convenient for connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com