A smart hydrogel with dual response and adjustable response behavior and its preparation method

An adjustable, double-response technology, applied in the field of functional materials, can solve the problems of unfavorable commercial production application, high production cost, complex process, etc., and achieve the effect of broad industrial application prospects, easy mass production, and convenient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

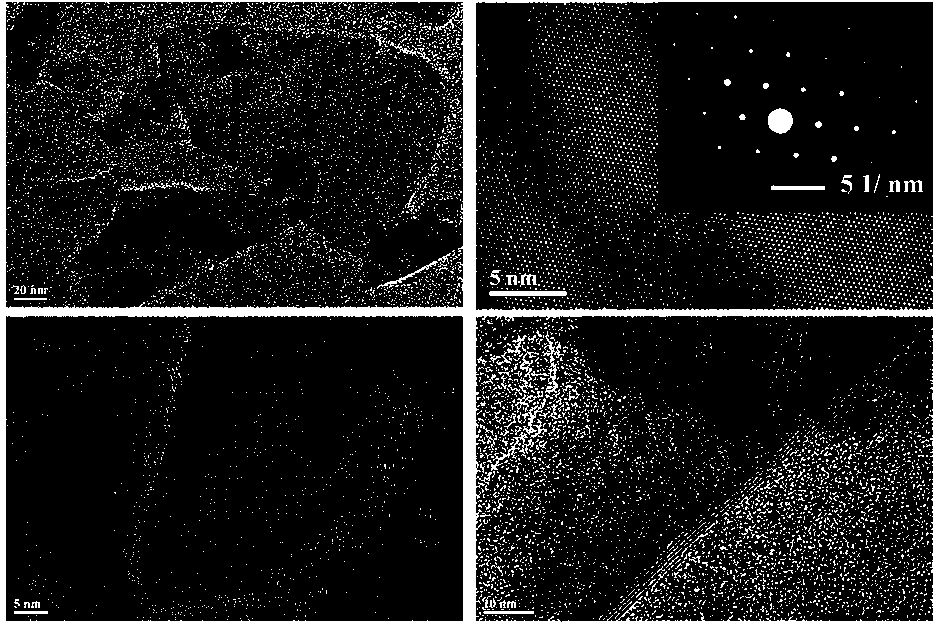

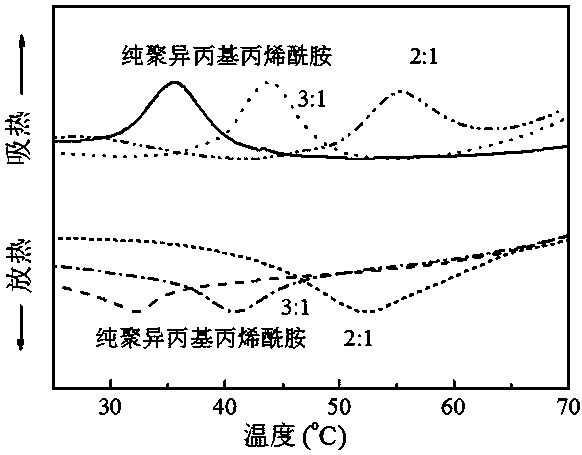

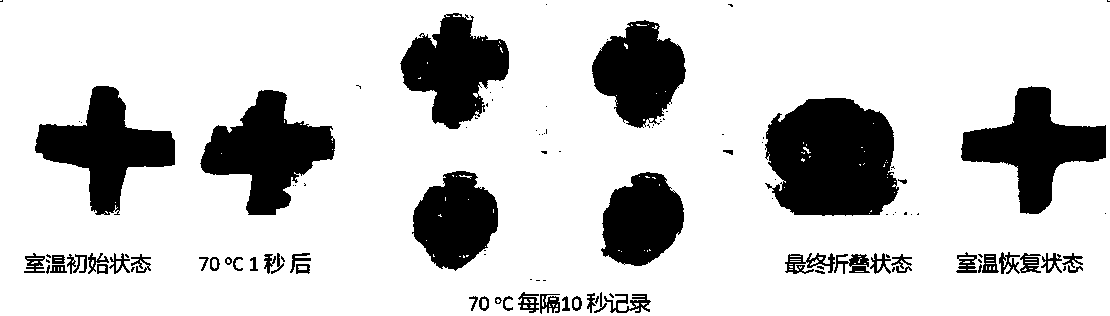

[0025] Disperse 1 g of molybdenum disulfide powder and 5 g of carboxylated chitosan powder in 250 mL of water, sonicate for 8 h, and collect the supernatant by centrifuging the aqueous solution after sonication to obtain non-covalently modified molybdenum carboxylated chitosan. Aqueous solution of nanosheets of molybdenum sulfide. Take 5 mL of the prepared nanosheet aqueous solution, add 1 g of N-isopropylacrylamide monomer, 0.3 g of dimethylacrylamide monomer, 0.2 g of lithium diatomaceous earth, and 0.005 g of cross-linking agent N,N- Methylbisacrylamide and 0.012 g initiator ammonium persulfate, 0.006 g tetramethylethylenediamine, mixed evenly, poured into a polytetrafluoroethylene mold, and reacted for 24 hours under nitrogen protection at room temperature to obtain transition metal disulfide A single-layer composite gel of compound nanosheets; then add 1.5 g dimethylacrylamide monomer, 0.1 g carboxylated chitosan, 0.2 g lithium diatomaceous earth, and 0.005 g cross-linkin...

Embodiment 2

[0031] Disperse 0.1 g of tungsten disulfide powder and 0.05 g of carboxylated chitosan powder in 250 mL of water, sonicate for 48 hours, and collect the supernatant by centrifuging the ultrasonic solution to obtain non-covalently modified carboxylated chitosan disulfide Aqueous solution of tungsten nanosheets. Take 5 mL of the prepared nanosheet aqueous solution, add 0.06 g of N-isopropylacrylamide monomer, 0.19 g of dimethylacrylamide monomer, 0.025 g of lithium diatomaceous earth, and 0.0125 g of cross-linking agent N,N- Methyl bisacrylamide and 0.00025 g initiator ammonium persulfate, 0.00025 g tetramethylethylenediamine, mixed evenly, poured into a polytetrafluoroethylene mold, and reacted for 1 hour at room temperature under nitrogen protection to obtain transition metal disulfide A single-layer composite gel of compound nanosheets; then add 0.25 g dimethylacrylamide monomer, 0.001 g carboxylated chitosan, 0.025 g lithium diatomaceous earth, and 0.0125 g cross-linking age...

Embodiment 3

[0033] Disperse 0.5 g of molybdenum diselenide powder and 2.5 g of carboxylated chitosan powder in 250 mL of water, sonicate for 10 h, and centrifuge the ultrasonic solution to collect the supernatant to obtain the carboxylated chitosan modified non-covalently. Aqueous solution of nanosheets of molybdenum selenide. Take 5 mL of the prepared nanosheet aqueous solution, add 0.5 g oligoethylene glycol methyl ether methacrylate monomer, 0.5 g dimethylacrylamide monomer, 0.02 g lithium diatomaceous earth, 0.3 g crosslinking agent N , N-methylenebisacrylamide and 0.01 g of initiator ammonium persulfate, 0.001 g of tetramethylethylenediamine, mixed evenly, poured into a polytetrafluoroethylene mold, and reacted for 24 hours at room temperature under nitrogen protection to obtain Single-layer composite gel of transition metal dichalcogenide nanosheets; then add 1 g dimethylacrylamide monomer, 0.05 g carboxylated chitosan, 0.02 g lithium diatomaceous earth, 0.3 g crosslinker N, N-meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com