Stripping, functional modification of dichalcogen compounds and preparation method of intelligent composite gel

A compound and dichalcogen technology, applied in the direction of binary selenium/telluride compounds, metal selenide/telluride, tungsten compounds, etc., can solve the problem of preparing transition metal dichalcogen compound composite materials, functional modification reports are very few, There are no problems such as functionality, and the effect of simple preparation conditions, broad industrial application prospects, and convenient operation process is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 0.84 g of N-isopropylacrylamide monomer and 0.36 g of vinylimidazole monomer in 50 mL of deionized water, then add 0.2 g of n-bromobutane and 0.054 g of azobisisobutylamidine hydrochloride, Heat and stir at 70°C for 4 hours to obtain a copolymer of polyvinylimidazole ionic liquid and N-isopropylacrylamide, and the polymer after dialysis is made into an aqueous solution with a concentration of about 2 wt%, which is used for ultrasonic stripping of molybdenum diselenide powder8 hours, to obtain an aqueous solution of polymer-modified molybdenum diselenide nanosheets, after centrifugation, the supernatant was taken, and 0.2 g of dibromobutane was added and heated at 70°C for 6 hours to obtain a composite gel.

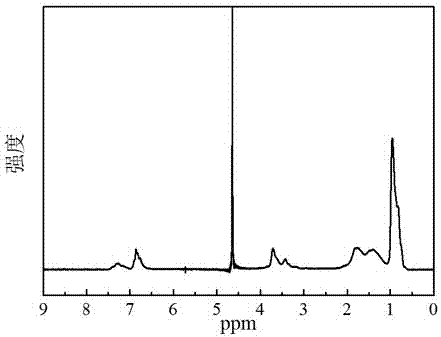

[0023] From figure 1 The NMR spectrum shows that the copolymer of polyvinylimidazole ionic liquid and N-isopropylacrylamide has been successfully prepared.

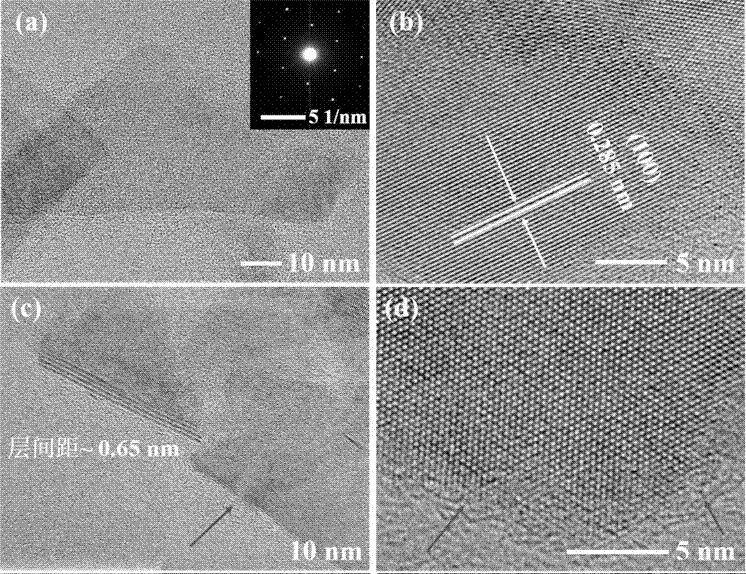

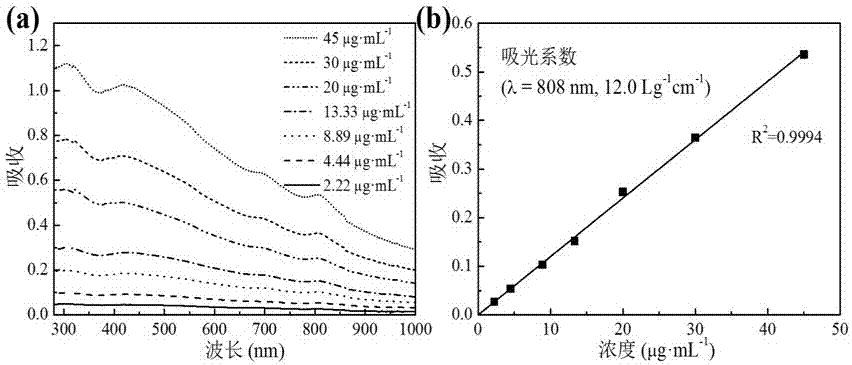

[0024] From figure 2 It can be seen in the figure that the lattice spacing of the exfoliated mol...

Embodiment 2

[0030]Dissolve 0.84 g of N-isopropylacrylamide monomer and 0.72 g of vinylimidazole monomer in 50 mL of deionized water, then add 0.4 g of n-bromobutane and 0.054 g of azobisisobutylamidine hydrochloride, Heat and stir at 70°C for 4 hours to obtain a copolymer of polyvinylimidazole ionic liquid and N-isopropylacrylamide, and the polymer after dialysis is made into an aqueous solution with a concentration of about 2 wt%, which is used for ultrasonic stripping of molybdenum diselenide powder8 hours, to obtain an aqueous solution of polymer-modified molybdenum diselenide nanosheets, after centrifugation, the supernatant was taken, and 0.2 g of dibromobutane was added and heated at 70°C for 6 hours to obtain a composite gel.

Embodiment 3

[0032] Dissolve 0.84 g of N-isopropylacrylamide monomer and 1.44 g of vinylimidazole monomer in 50 mL of deionized water, then add 0.8 g of n-bromobutane and 0.054 g of azobisisobutylamidine hydrochloride, Heat and stir at 70°C for 4 hours to obtain a copolymer of polyvinylimidazole ionic liquid and N-isopropylacrylamide, and the polymer after dialysis is made into an aqueous solution with a concentration of about 1 wt%, which is used for ultrasonic stripping of molybdenum diselenide powder5 hours, to obtain an aqueous solution of polymer-modified molybdenum diselenide nanosheets, after centrifugation, the supernatant was taken, and 0.2 g of dibromobutane was added and heated at 60° C. for 7 hours to obtain a composite gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| photothermal conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com