A kind of transition metal dichalcogenide nanosheet composite and preparation method thereof

A transition metal, nanosheet technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. Solvent pollution and other problems, to achieve the effect of broad industrial application prospects, easy mass production, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

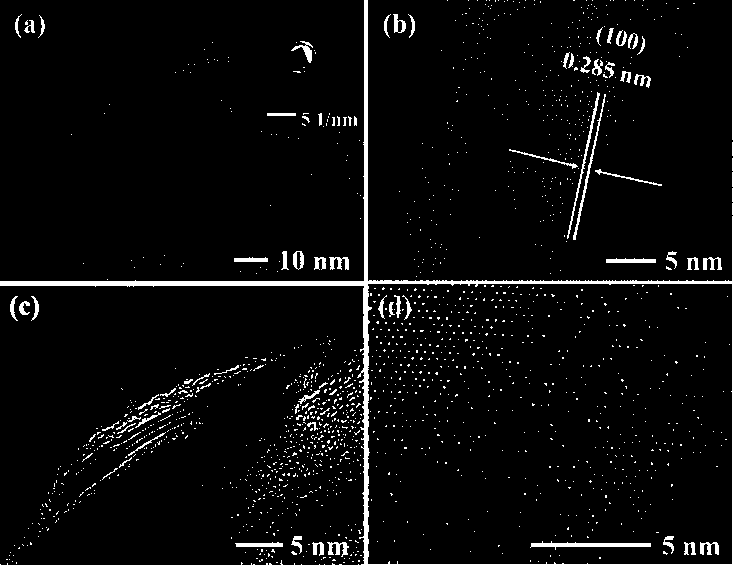

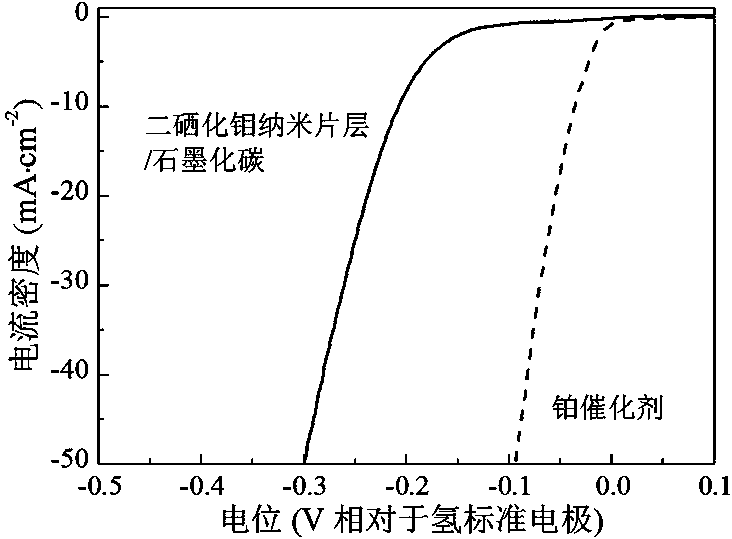

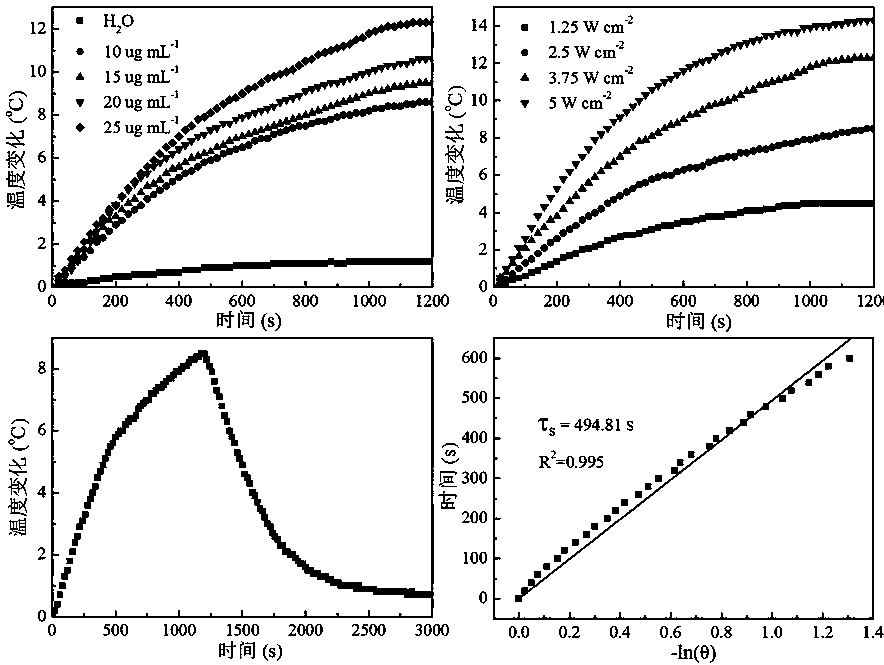

[0026]Disperse 1 g of molybdenum diselenide powder and 0.5 g of polyvinylpyrrolidone (K30) in 250 mL of water, sonicate for 8 hours, and centrifuge the ultrasonic solution to collect the supernatant to obtain the non-covalently modified transition metal disulfide Aqueous solutions of nanosheets of metal compounds. The prepared aqueous solution of nanosheets can be centrifuged at 3000 rpm for 30 min at a high speed, then freeze-dried for 24 h to obtain nanosheets of polymer-modified transition metal dichalcogenides, and then heat-treated at 600 °C to obtain transition metal dichalcogenides. The compound of chalcogenide / graphitized carbon is used as an efficient catalyst for hydrogen evolution reaction; take 5 mL of the prepared nanosheet aqueous solution, add 0.5 g N-isopropylacrylamide monomer, 0.01 g cross-linking agent N,N- Methylenebisacrylamide and 0.005 g initiator ammonium persulfate were hydrothermally reacted at 180 °C for 4 h to obtain a transition metal dichalcogenid...

Embodiment 2

[0033] Disperse 0.1 g of molybdenum disulfide powder and 0.5 g of polyvinylpyrrolidone (K30) in 250 mL of water, sonicate for 5 h, and collect the supernatant by centrifuging the sonicated aqueous solution to obtain the non-covalently modified transition metal disulfide Aqueous solutions of nanosheets of metal compounds. The prepared aqueous solution of nanosheets can be centrifuged at 30,000 rpm for 10 min, then freeze-dried for 12 h to obtain nanosheets of polymer-modified transition metal dichalcogenides, and then heat-treated at 800 °C to obtain transition metal dichalcogenides The compound of metal compound / graphitized carbon is used as a high-efficiency catalyst for hydrogen evolution reaction; take 5 mL of the prepared nanosheet aqueous solution, add 0.5 g N-vinylcaprolactam, 0.01 g cross-linking agent N,N-methylenebispropylene Amide and 0.005 g initiator ammonium persulfate were hydrothermally reacted at 120 °C for 3 h to obtain a transition metal dichalcogenide nanosh...

Embodiment 3

[0035] Disperse 0.3 g of tungsten disulfide powder and 0.1 g of polyvinylpyrrolidone (K30) in 250 mL of water, sonicate for 8 h, and centrifuge the sonicated aqueous solution to collect the supernatant to obtain the non-covalently modified transition metal disulfide Aqueous solutions of nanosheets of metal compounds. The prepared aqueous solution of nanosheets can be centrifuged at 10000 rpm for 60 min at high speed, then freeze-dried for 24 h to obtain nanosheets of polymer-modified transition metal dichalcogenides, and then heat-treated at 800 °C to obtain transition metal dichalcogenides. The composite of chalcogenide / graphitized carbon is used as an efficient catalyst for hydrogen evolution reaction; take 5 mL of the prepared nanosheet aqueous solution, add 1 g of oligoethylene glycol methyl ether methacrylate, 0.01 g of cross-linking agent N, N-methylenebisacrylamide and 0.001 g initiator ammonium persulfate were hydrothermally reacted at 150 °C for 8 h to obtain a transi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| photothermal conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com