Double diaphragm steady flow anti-drip valve

An anti-drip valve and steady flow technology, which is applied in the direction of diaphragm valve, diaphragm, safety valve, etc., can solve the problems that the steady flow and anti-drip can not be realized at the same time, the fog cannot be formed, the flow is uneven, etc., and the structural design is novel, The effect of low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

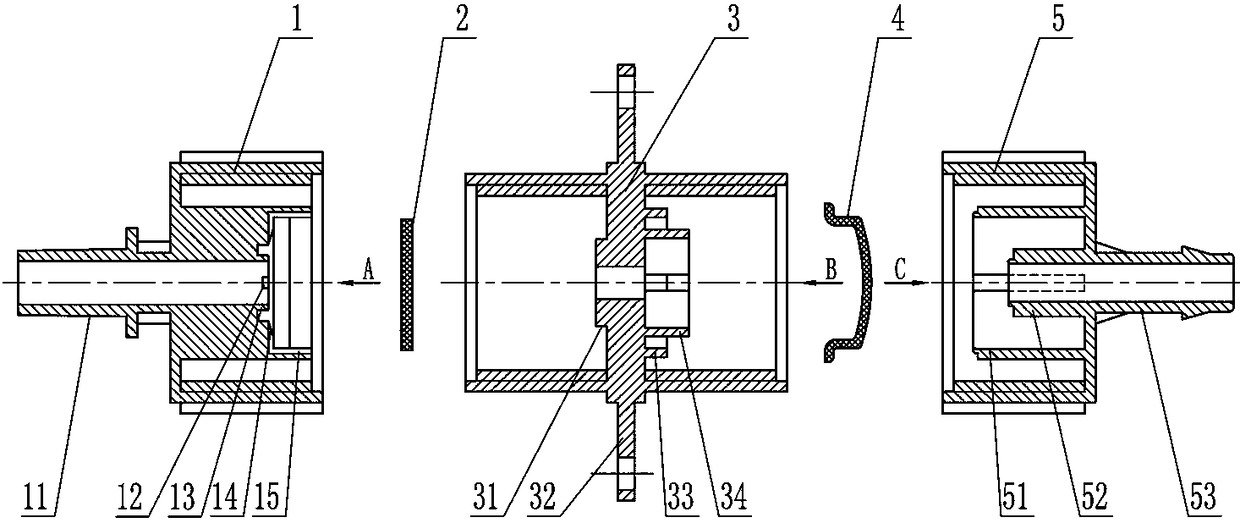

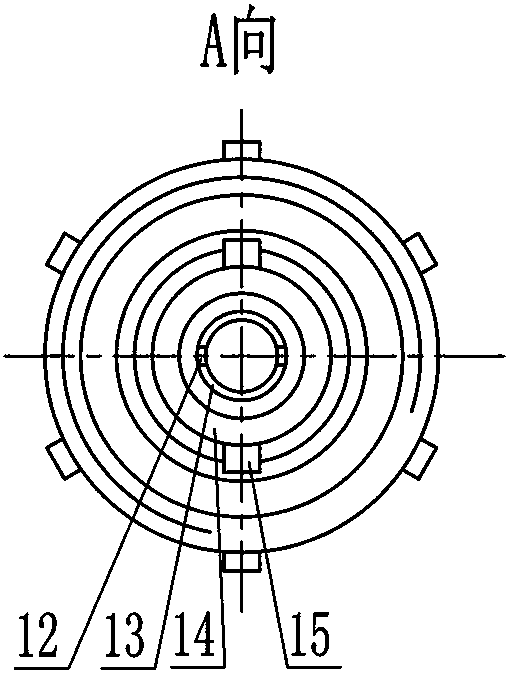

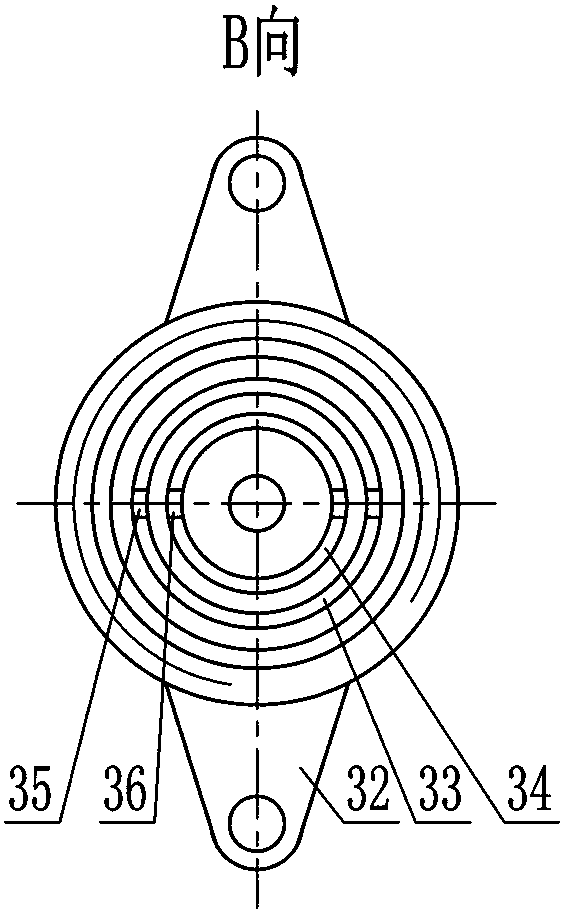

[0044] Such as Figure 1 to Figure 5 The shown double-diaphragm steady-flow anti-drip valve includes a steady-flow casing 1 , a steady-flow diaphragm 2 , an intermediate casing 3 , an anti-drip diaphragm 4 , and an anti-drip casing 5 .

[0045] One end of the steady flow casing 1 is connected to the micro-spray head 7 through a water outlet joint 11 , and the other end is connected to the left side of the middle casing 3 . The outer surface of the water outlet joint 11 has a taper of 1.2:100, and is closely matched with the micro-spray head 7 through the taper.

[0046] One end of the drip-proof housing 5 is connected to the water delivery pipe through an oblique water inlet joint 53 , and the other end is connected to the right side of the middle housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com