Eccentric cam flow regulation control valve

A flow adjustment, cam-type technology, applied in safety valves, balance valves, valve devices, etc., can solve the problems of high processing technology requirements for cones and cone cocks, troublesome assembly and debugging, and high manufacturing costs, and achieve low manufacturing costs. Convenience and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

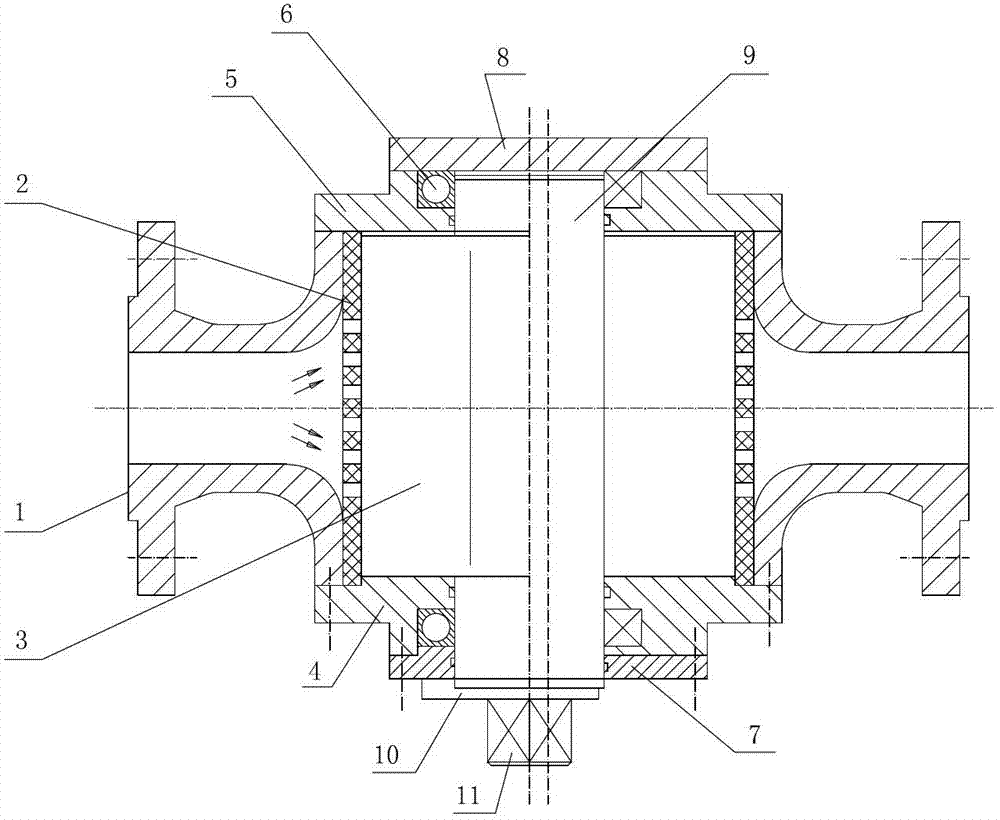

[0017] The embodiment of the present invention is mainly composed of a valve body 1, a valve core, a sealing lining 2, a bearing 6, bearing seats 4, 5, and bearing seat covers 7, 8,

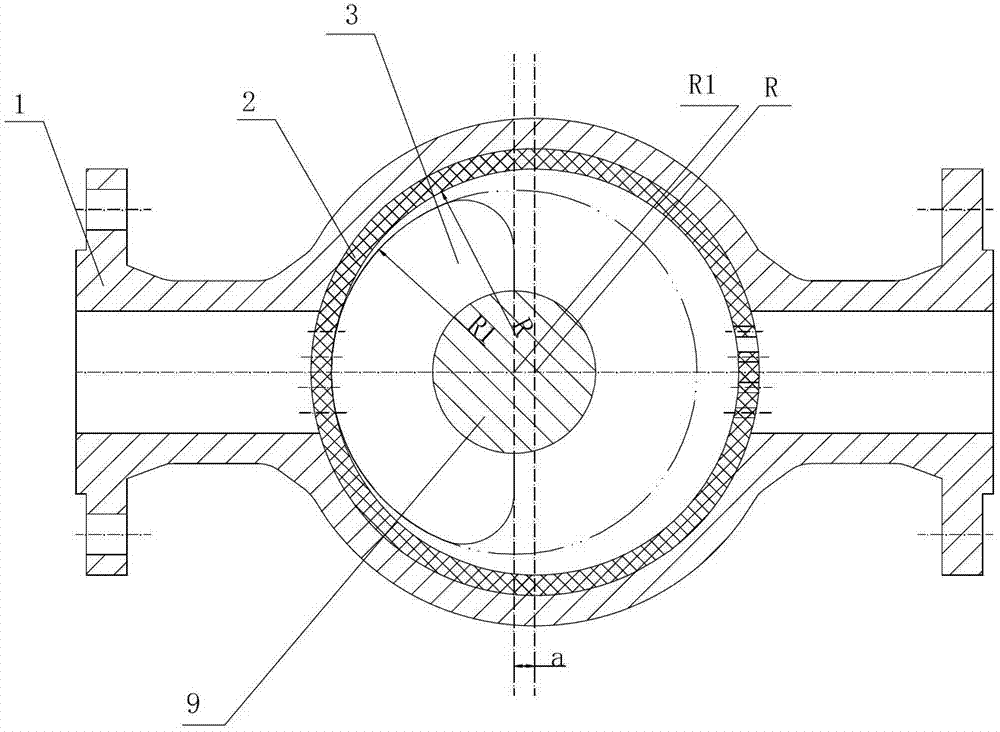

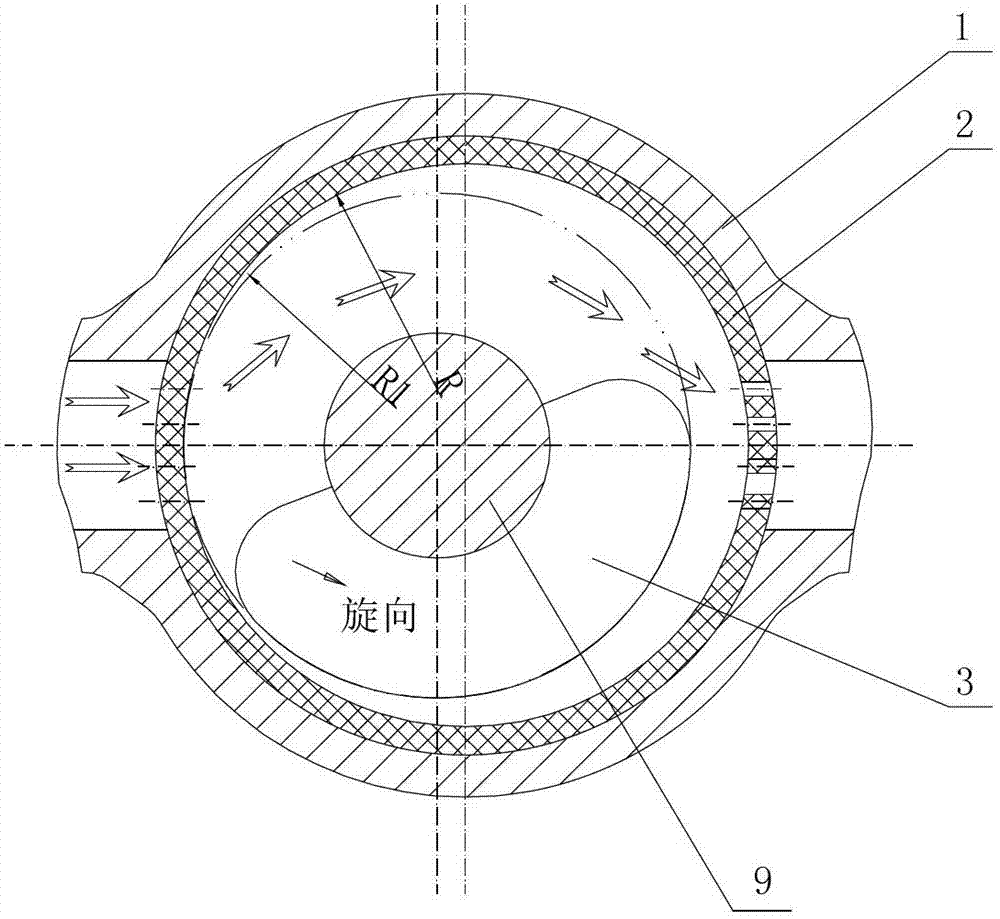

[0018] The spool is composed of a mandrel 9 and a cam 3. The cam 3 is arranged on the mandrel 9. The two are an integral casting, or the two are fixedly connected as a whole by bolts or connecting pieces. The cam 3 is a semi-cylindrical body with arc chamfers, and the center of the semi-cylindrical body of the cam 3 and the axis center of the mandrel 9 are the same center R1.

[0019] The valve core is arranged in the valve chamber of the valve body 1, and the core shaft 9 of the valve core is arranged eccentrically with the valve chamber. The two ends of the core shaft 9 of the valve core are supported on the valve body 1 by the bearing 6 and the bearing seats 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com