A kind of falling material flow sampling device

A sampling device and blanking technology, applied in the direction of sampling devices, etc., can solve the problems of losing fairness and justice, affecting the normal sampling of samples, and not breaking, etc., to achieve a fair and just effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

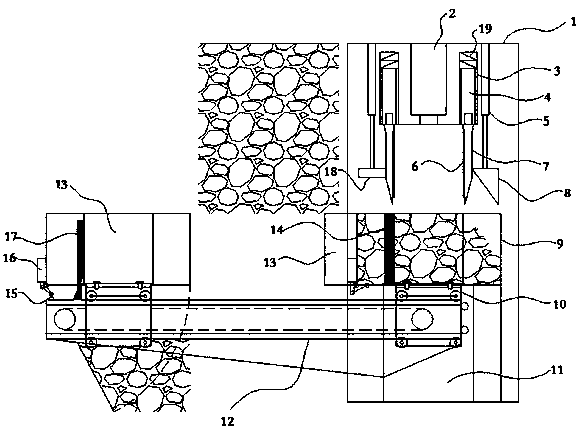

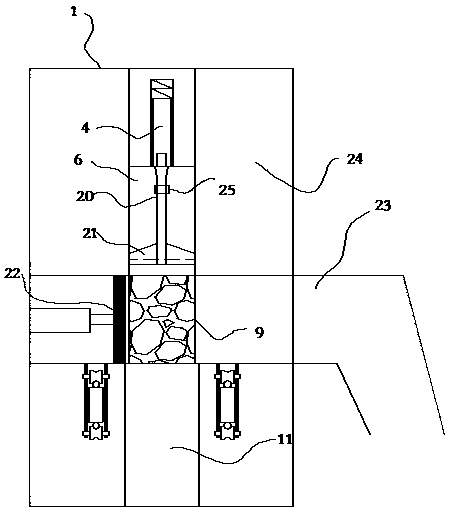

[0018] Such as figure 1 , 2 As shown, a kind of blanking flow sampling device of the present invention includes a support frame 1, and the support frame 1 plays a supporting role, which can provide relatively large action force and reaction force so as to impact and shear larger hard material particles such as stones. . The top of the support frame 1 is vertically suspended with a main elevating mechanism 2, the lower end of the main elevating mechanism 2 is connected with a supporting horizontal plate, and two material limiting plates 6 are arranged below the supporting horizontal plate, and the two material limiting plates 6 are vertically arranged in parallel. There is a gap between them to facilitate the entry of materials. A support platform 11 is provided in the middle of the bottom of the support frame 1, and the support frame on the front and rear sides of the support platform 11 is provided with a transmission track 12 extending to the left. On the track 12 and mov...

Embodiment 2

[0025] Embodiment two: when softer material or even small particle material is sampled, save the impact sampler 7 in embodiment one, main elevating mechanism 2 drives material limiter plate 6 to directly shear the middle of receiving box 9 For material sampling, the material limiting plate 6 plays a shearing role while storing the material, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com