Electric connector

An electrical connector and docking part technology, applied in the field of reversible pluggable electrical connectors, can solve the problems of reduced strength of inserted components, many assembly parts, reduced product reliability, etc., to avoid mutual influence and facilitate injection molding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

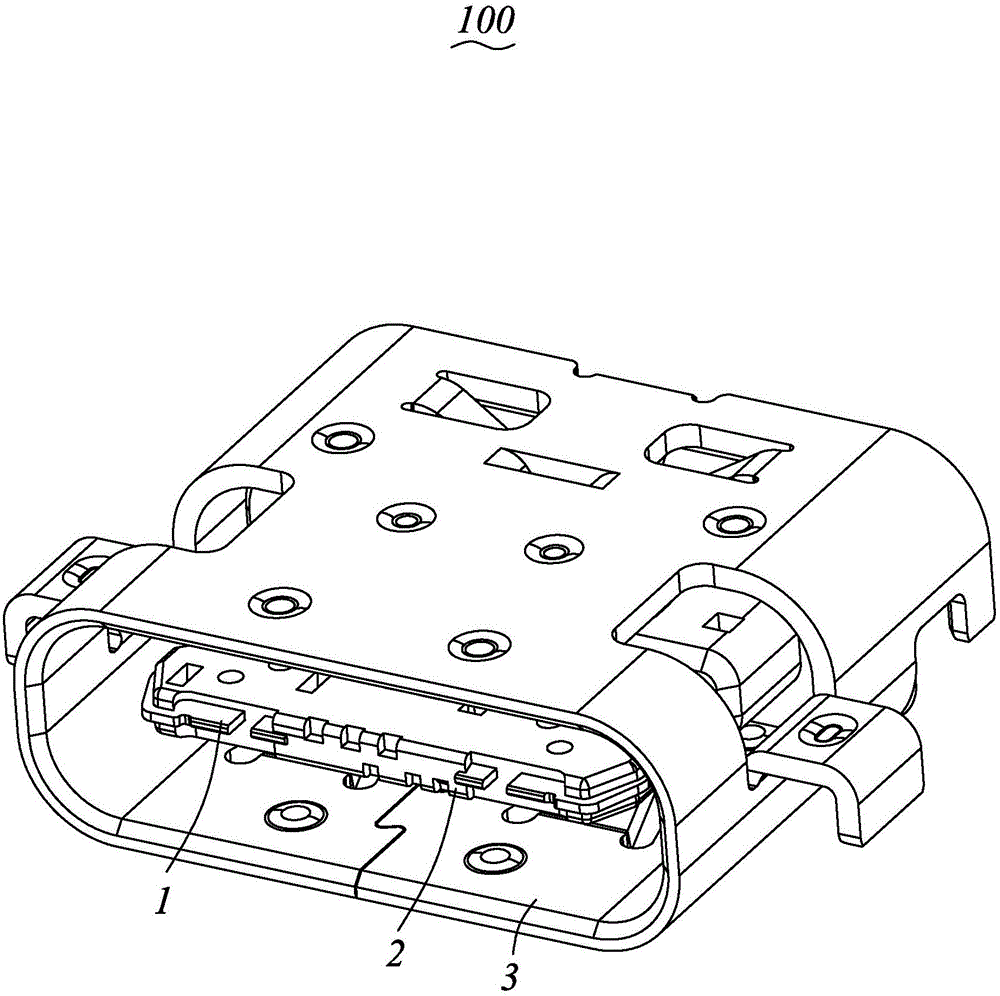

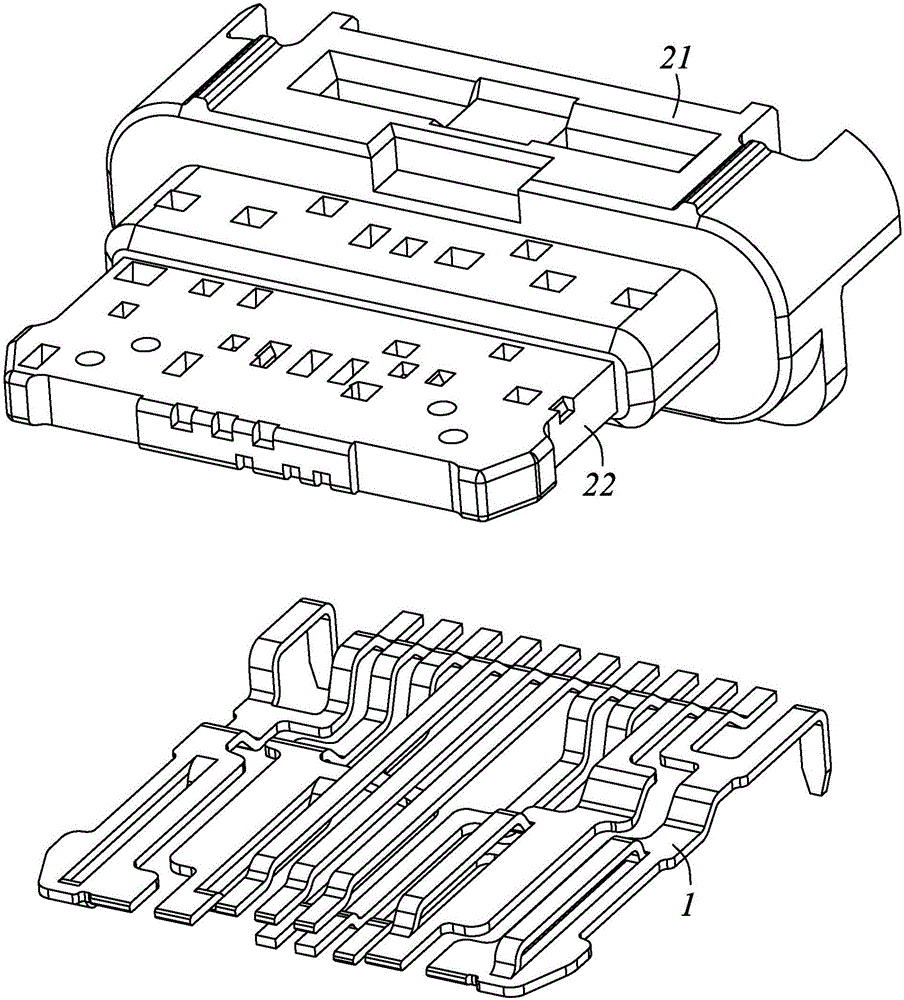

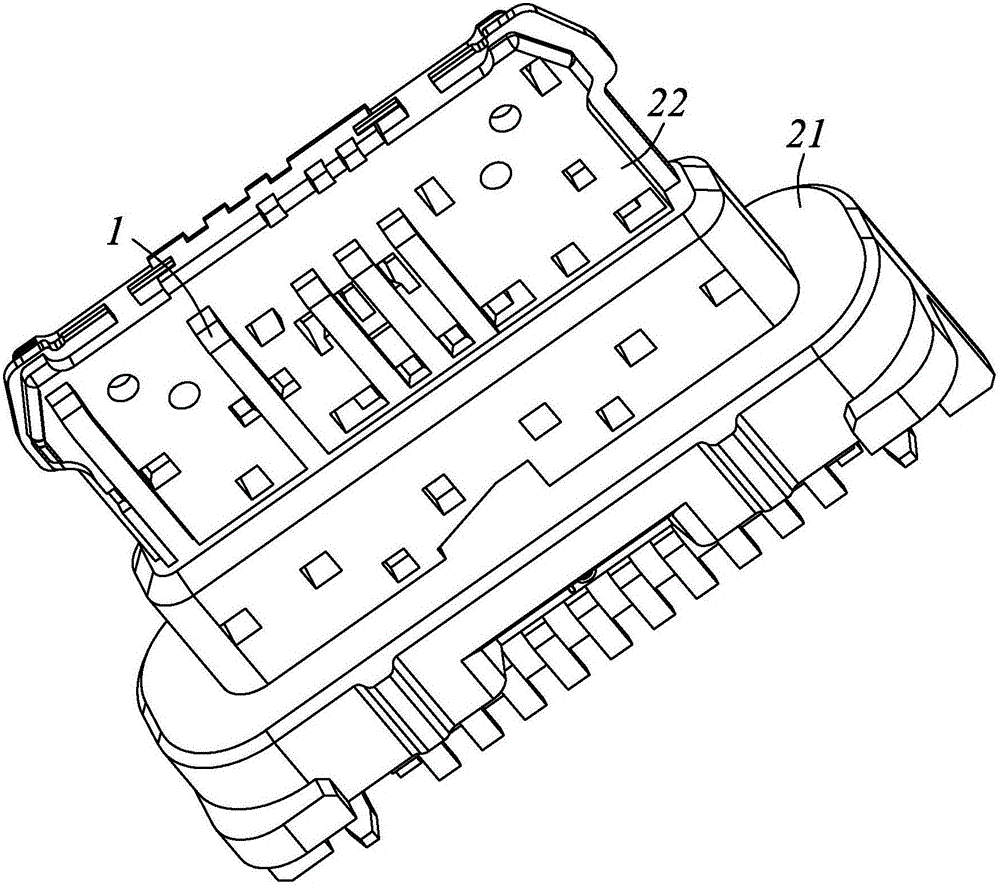

[0028] Please refer to Figure 1 to Figure 9 As shown, it is a preferred embodiment of the electrical connector 100 of the present invention. The electrical connector 100 includes a plurality of conductive terminals 1, an insulating body 2 injection-molded on the periphery of the conductive terminals 1, and an insulating body 2 coated on the insulating body 2. Outer shell 3.

[0029] Please Figure 1 to Figure 3 As shown, the insulating body 2 is integrally formed, and has a base 21 and a tongue 22 extending forward from the base.

[0030] Please refer to Figure 4 to Figure 9 As shown, the conductive terminal 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com