A method of making professional women's trousers with high heels

A production method and technology of high-heeled shoes, applied to trousers, tools for sewing clothes, etc., can solve the problems of not being able to continue wearing, easy to wear at the rear, and difficult to repair, so as to achieve resistance to wear, avoid wrinkling, and prevent fraying of the trouser legs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The invention specifically describes a method for making professional women's trousers with high-heeled shoes. First, typesetting and cutting are carried out on the fabric, and emphatically correcting the opening of the trousers so that it fits all kinds of high-heeled shoes. Finally, it is shaped, which specifically includes the following steps:

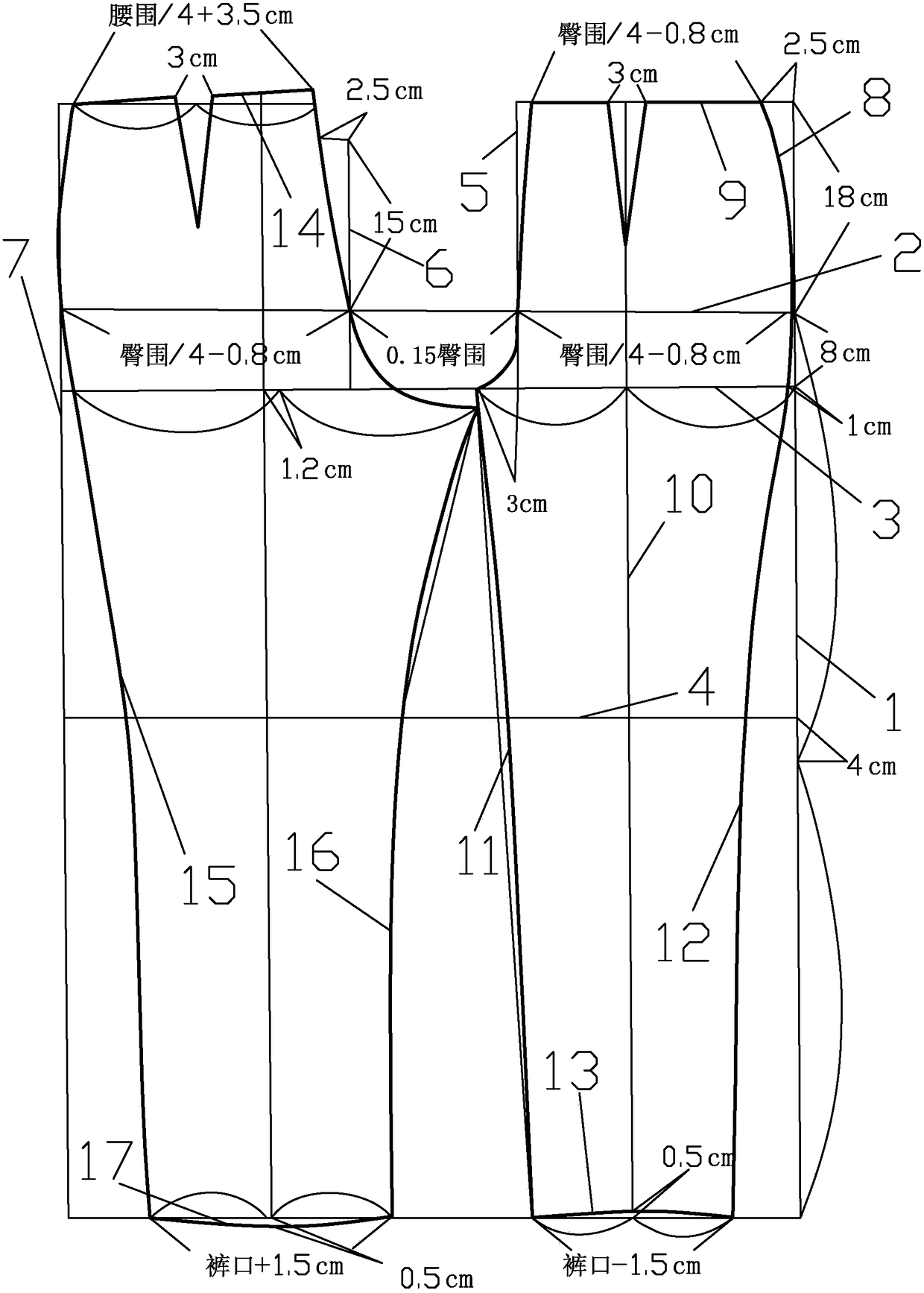

[0051](1) Draw the structural line on the fabric, the specific drawing is as follows (such as figure 1 ):

[0052] a. Draw a vertical base line and record it as line segment 1, which is 3cm shorter than the length of the trousers;

[0053] b. On the basis of line segment 1, draw a hip height line from the upper end point down to 18cm, and record it as line segment 2;

[0054] c. Draw a horizontal base line 8cm down from line segment 2, and record it as line segment 3;

[0055] d. After removing the part above line segment 2 from line segment 1, take the middle point, draw a horizontal structural line 4cm above the middle po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com