Guide plate type punching die

A guide plate type punching die and guide plate technology, applied in the field of punching die, can solve the problems of limited pressure of the pressing plate, difficulty in processing small holes, breakage of punches in assembly size, etc., and achieve good guiding conditions and are conducive to punching. Cutting, pressure and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following examples are a further description of the content of the present invention as an explanation of the technical content of the present invention, but the essential content of the present invention is not limited to the following examples, those of ordinary skill in the art can and should know any Simple changes or replacements of the essential spirit of the invention shall fall within the scope of protection required by the present invention.

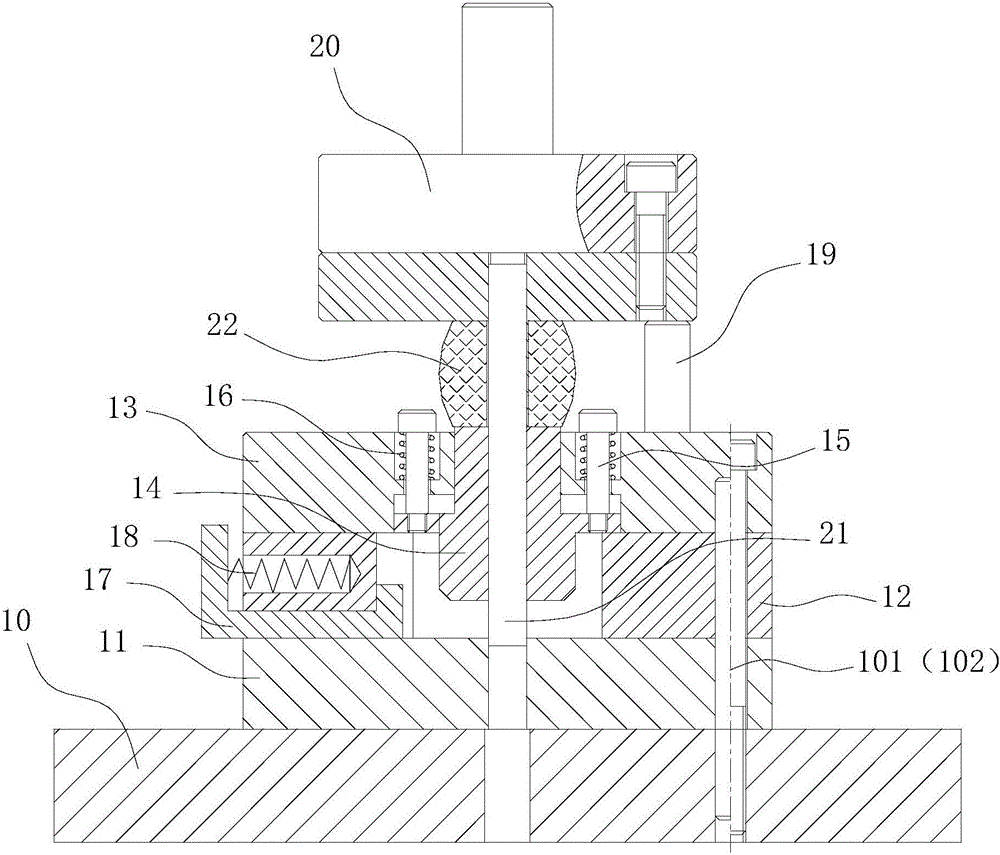

[0015] Such as figure 1 As shown, a guide plate type punching die includes a fixed lower die base 10 and an upper die base 20 reciprocating up and down. The upper die base 20 is provided with a punch 21, and the lower die base 10 is A die 11 is provided, a side guide plate 12 is provided above the die 11, a cavity for accommodating workpieces to be processed is provided in the middle of the side guide plate 12, a fixed plate 13 is provided above the side guide plate 12, and a through hole is provided in the middle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com