Heavy edge tearing knife rest convenient to adjust and working principle thereof

A tool holder and side knife technology, applied in metal processing and other directions, to achieve the effect of easy adjustment, easy installation, and loosening prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the implementation objectives, technical solutions and advantages of the present invention clearer, the solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

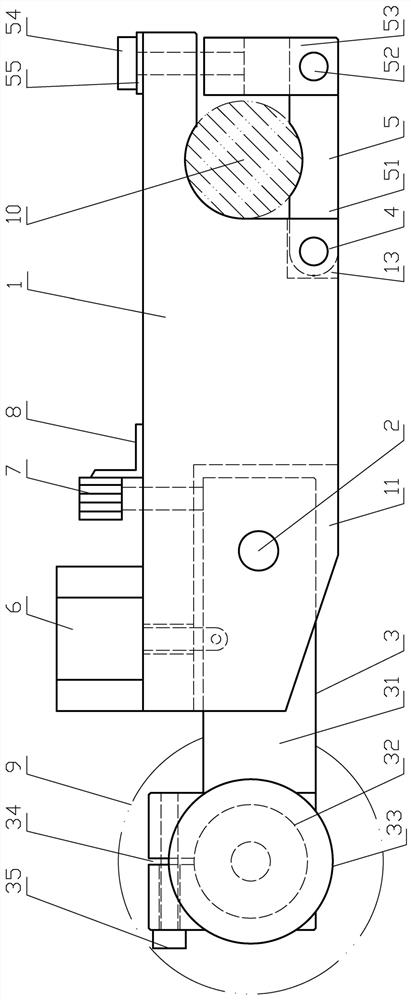

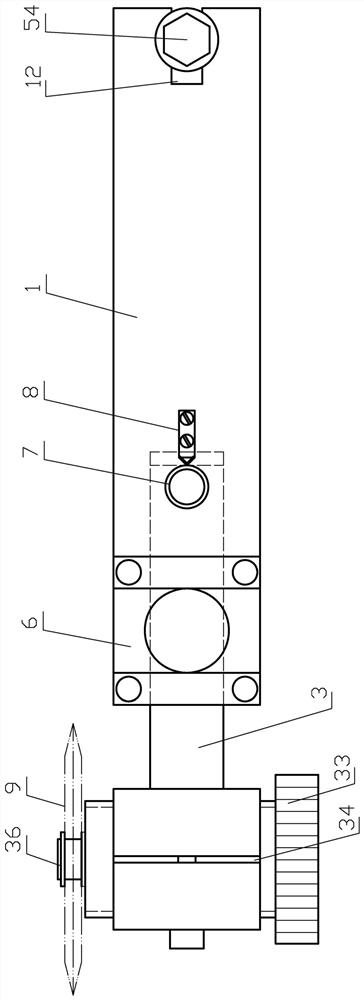

[0021] as attached figure 1 and figure 2 As shown, this conveniently adjustable heavy-duty tearing knife rest of the present invention includes a knife rest body 1, and a long fork 11 is arranged at the lower end of the head of the said knife rest body 1, and a straight pin I2 is hinged in the long fork 11. A tool holder head 3; the tail of the tool holder body 1 is in the shape of an inner arc at right angles, with a short fork opening 12 at the tail end and a right angle fork opening 13 at the lower end, and a cylindrical pin II 4 is used to hinge a shaft holding assembly in the right angle fork opening 13 5. The shaft holding assembly 5 includes a connecting block 51, one end of the connecting block 51 is hinged with the right ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com