A drilling and pressing riveting binding machine with automatic sharpening function

An automatic knife sharpening and binding machine technology, applied in binding, metal processing, etc., can solve the problems of high cost and complex structure, and achieve the effect of low cost, good knife sharpening effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

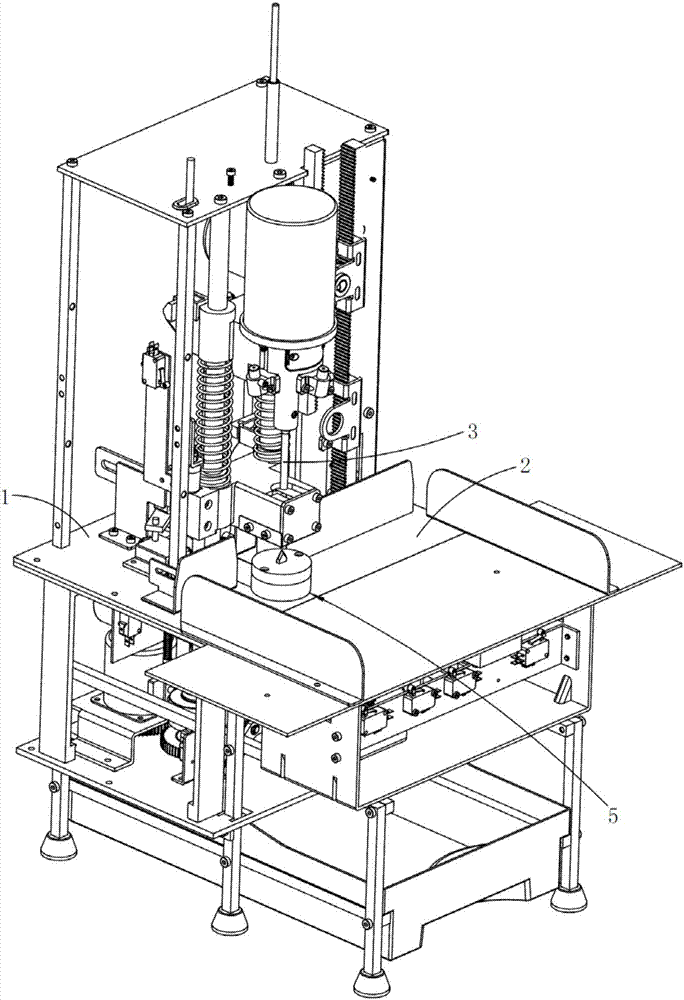

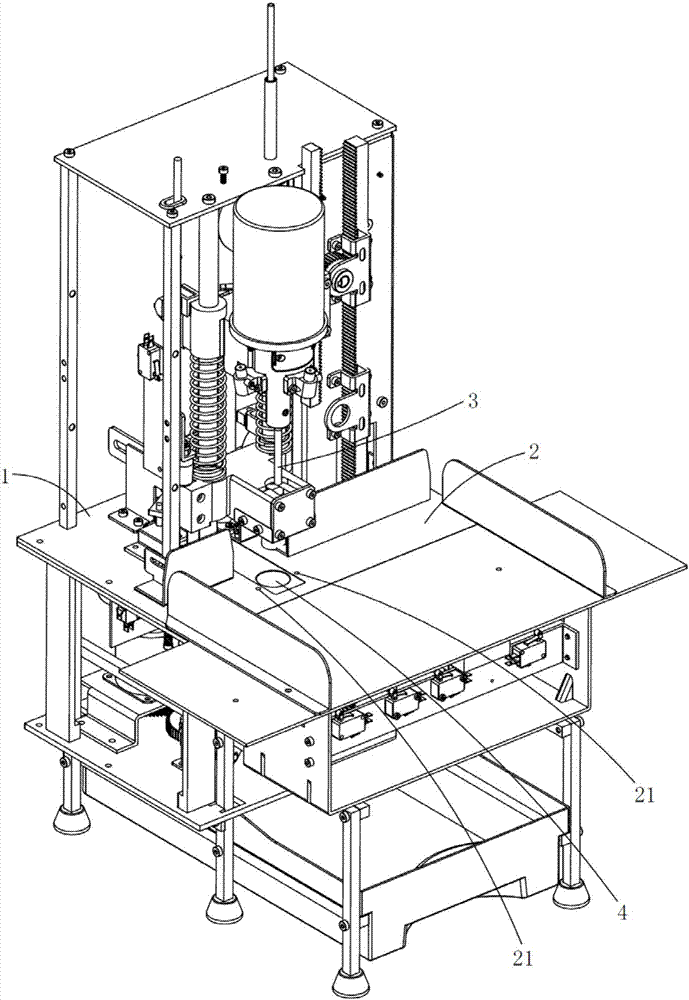

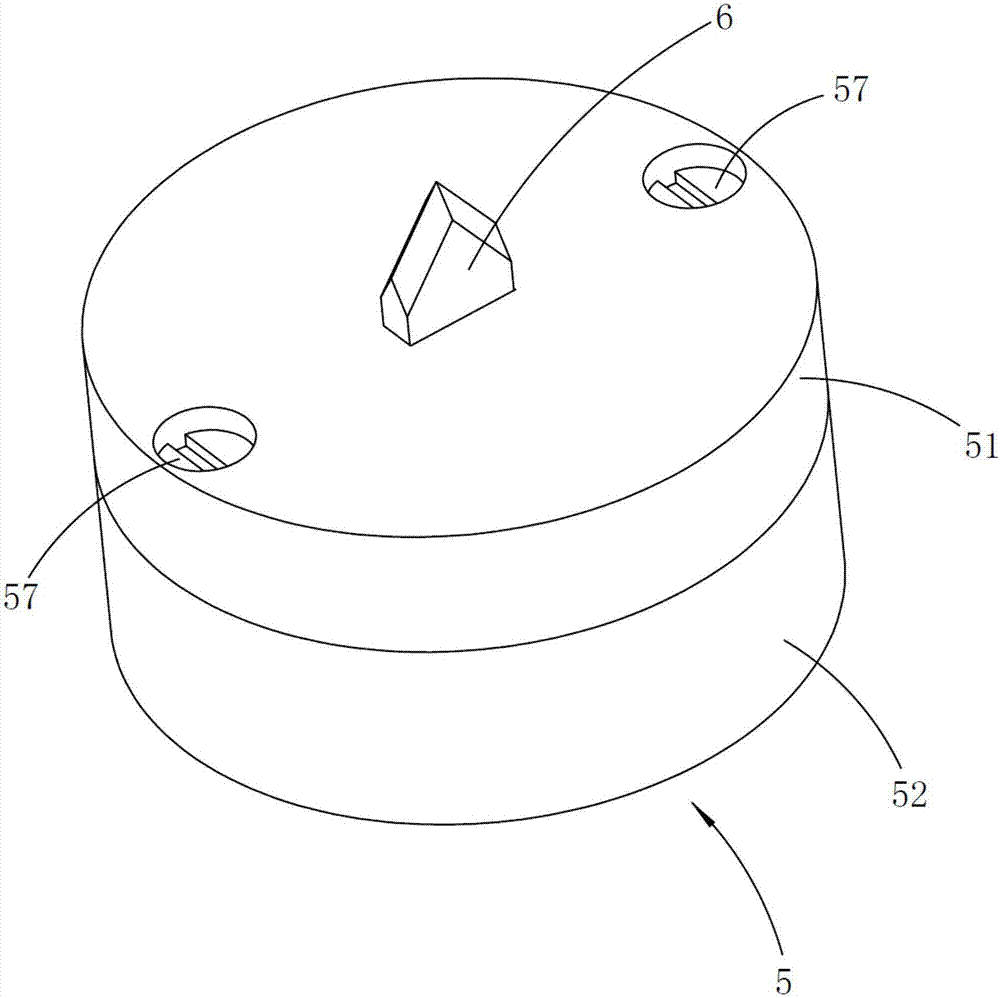

[0034] Examples, see Figure 1 to Figure 4 As shown, a drilling and riveting binding machine with automatic knife sharpening function includes a frame 1, a paper placing table 2 and a drill 3, the drill 3 is fixed at the lower end of the drilling motor, and the drill 3 is fixed by the motor For the guide sleeve, the guide sleeve slides up and down and is installed on the two main guide columns. The paper loading table 2 is provided with a conductive rubber pad 4 directly below the drill 3, and the bottom of the drill 3 is provided with a cutting edge for drilling and riveting binding. The machine is provided with two electrical signal pins. When the two electrical signal pins are electrically connected, the drilling press riveting binding machine drives the drill 3 to move upward, and the conductive rubber pad 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com