Novel cutter sharpener

A knife sharpener, a new type of technology, used in grinding/polishing equipment, grinding/polishing hand tools, metal processing equipment, etc. problem, to achieve the effect of simple, convenient and safe use, easy and labor-saving sharpening, and a wide range of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

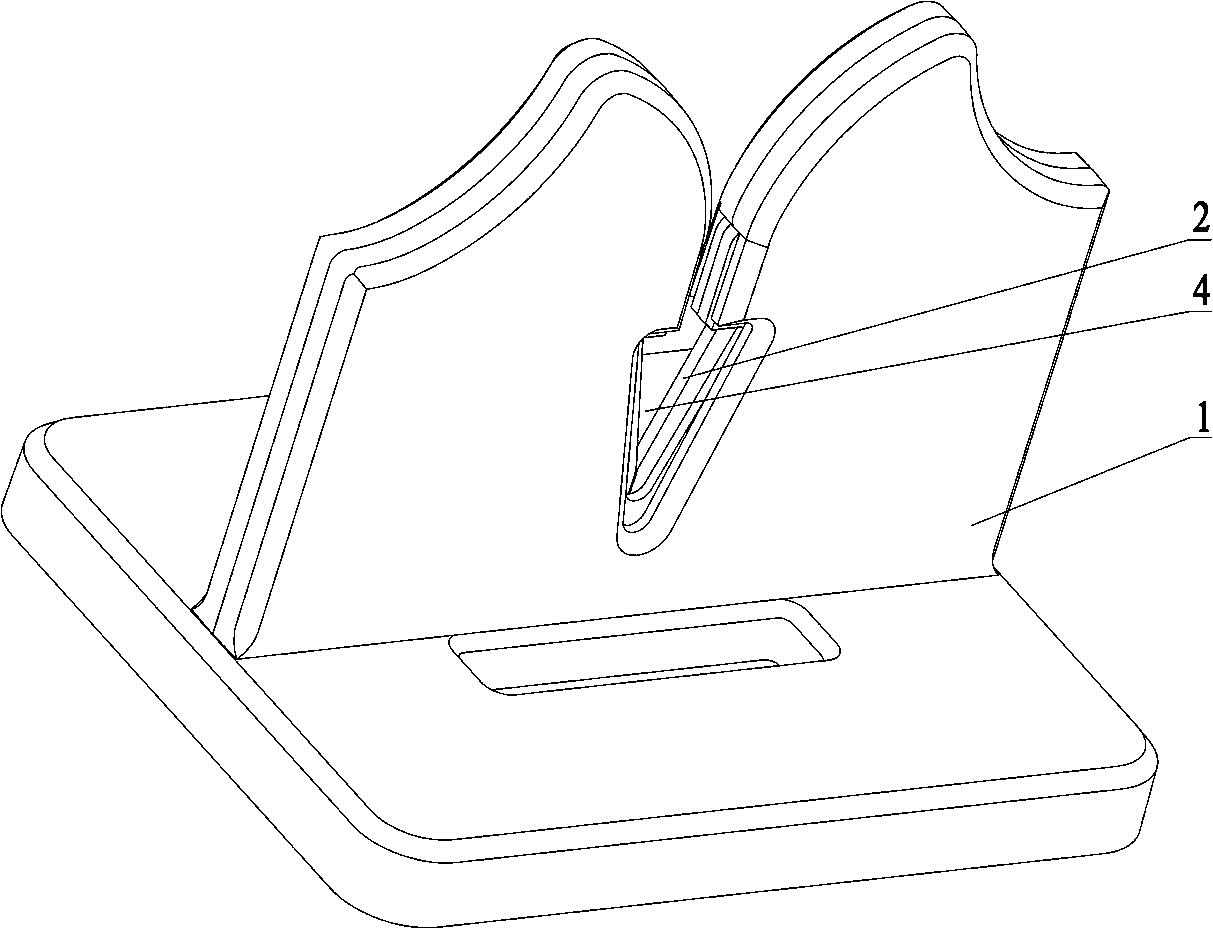

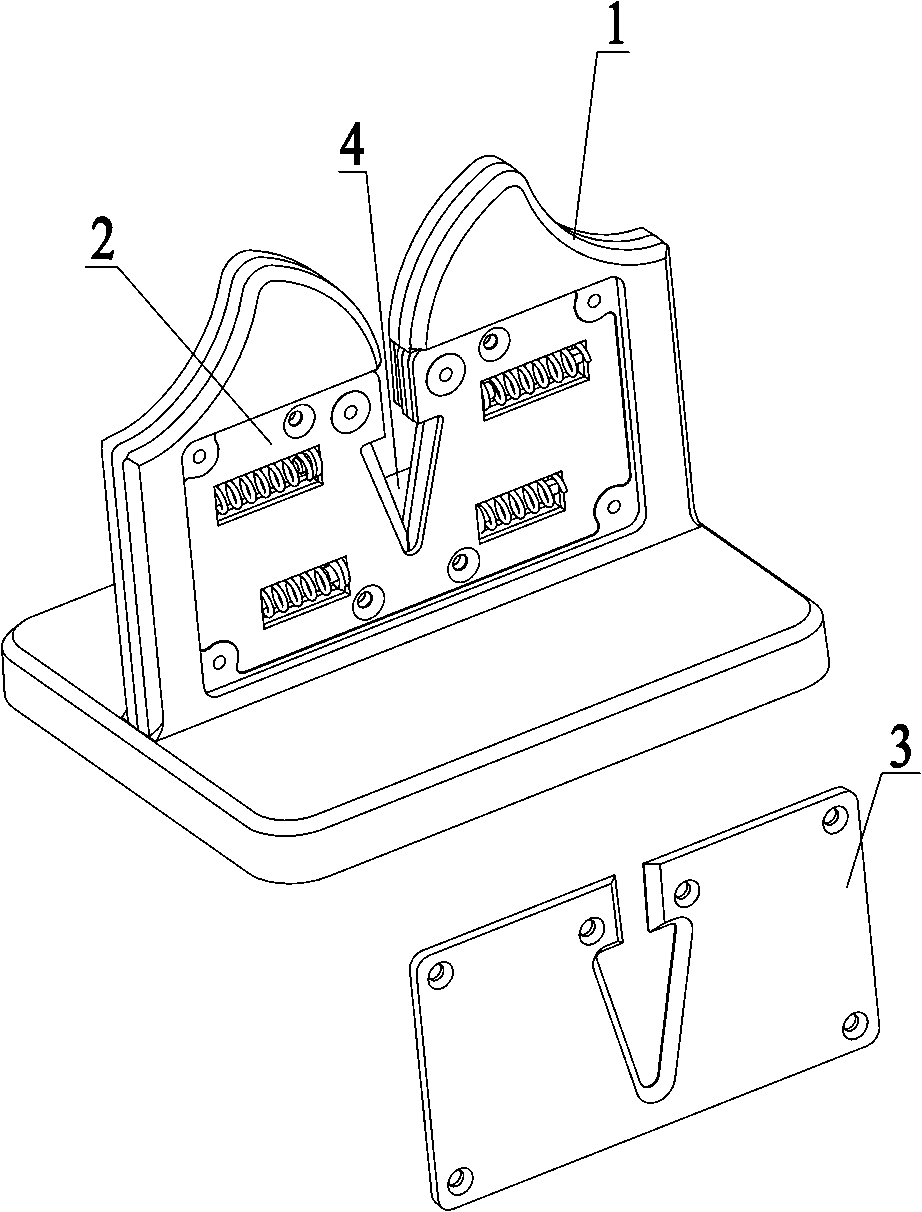

[0031] like figure 1 , figure 2 As shown, a new knife sharpener of the present invention includes an inverted "T" shaped knife sharpening seat 1, a knife sharpening assembly 2 installed on the back of the knife sharpening seat 1, and a cover plate 3 covering the knife sharpening assembly 2. The device is a left-right symmetrical structure with a "V" shape sharpening groove 4 extending downwards from the middle opening on the top and an inverted "T" shape on the side.

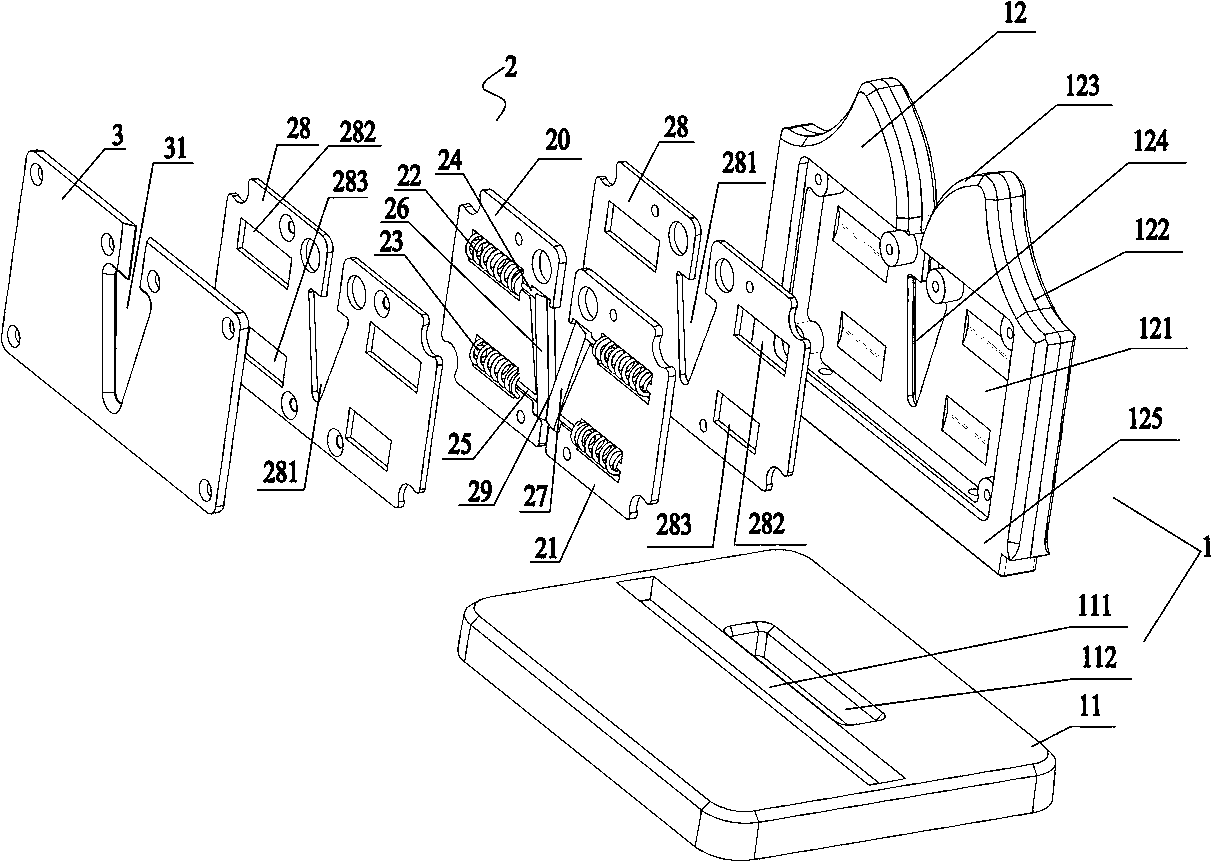

[0032] like image 3 , Figure 4 As shown, the sharpening seat 1 includes a base plate 11 and a mounting plate 12 arranged on the base plate 11. An oblique slot 111 is formed in the middle of the base plate 11, a chip drop groove 112 is formed in front of the oblique slot 111, and a mounting plate 12 is formed on the back of the mounting plate 12. The groove 121 of the kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com