Tool for testing voltage withstanding of patch optocoupler

A technology of withstand voltage test and optocoupler, which is used in the direction of testing dielectric strength, measuring device shell, etc., can solve the problem that the test tool is not suitable for batch testing, etc., and achieves convenient and safe use, easy to install optocoupler, and improve the experimental effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

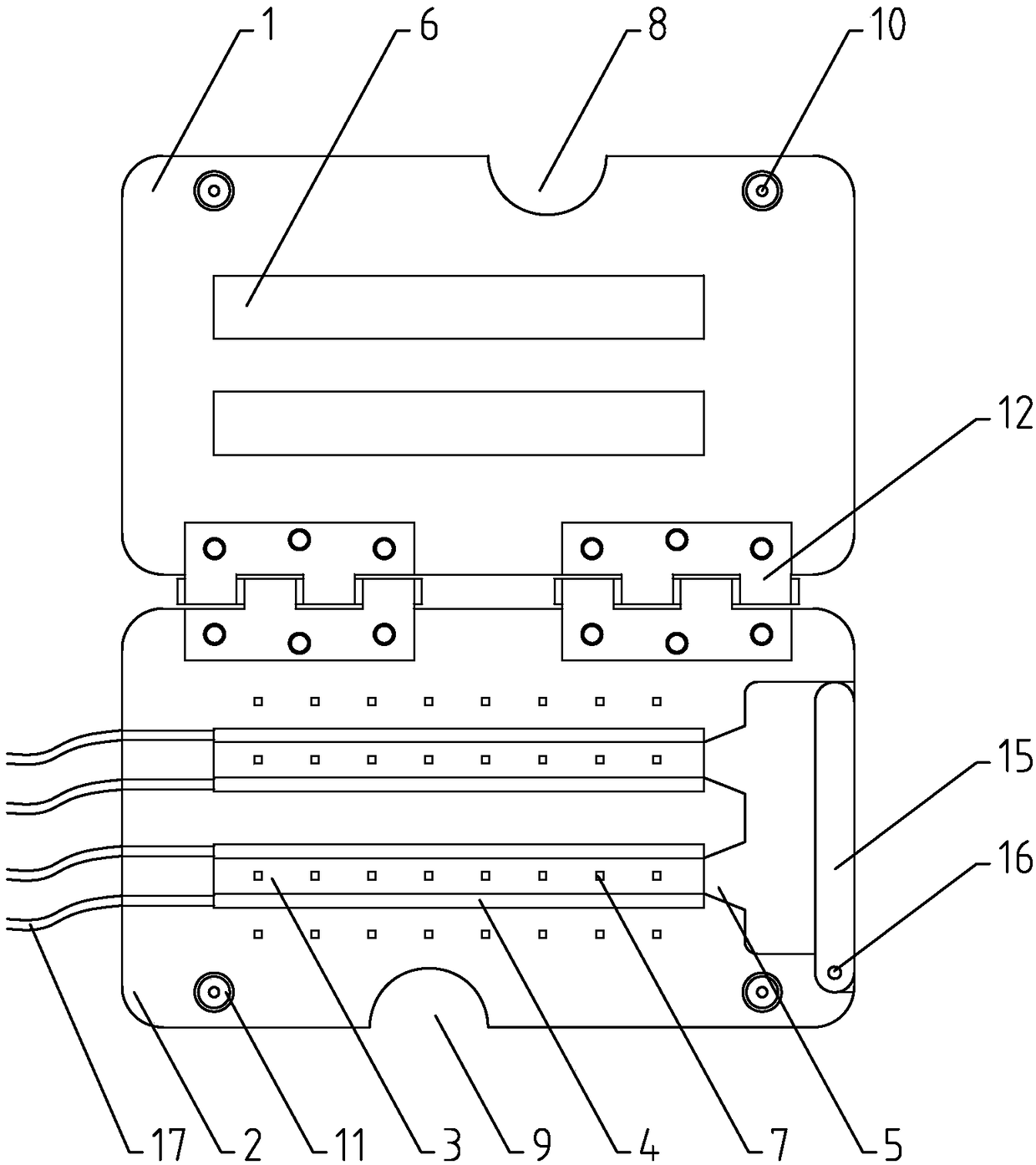

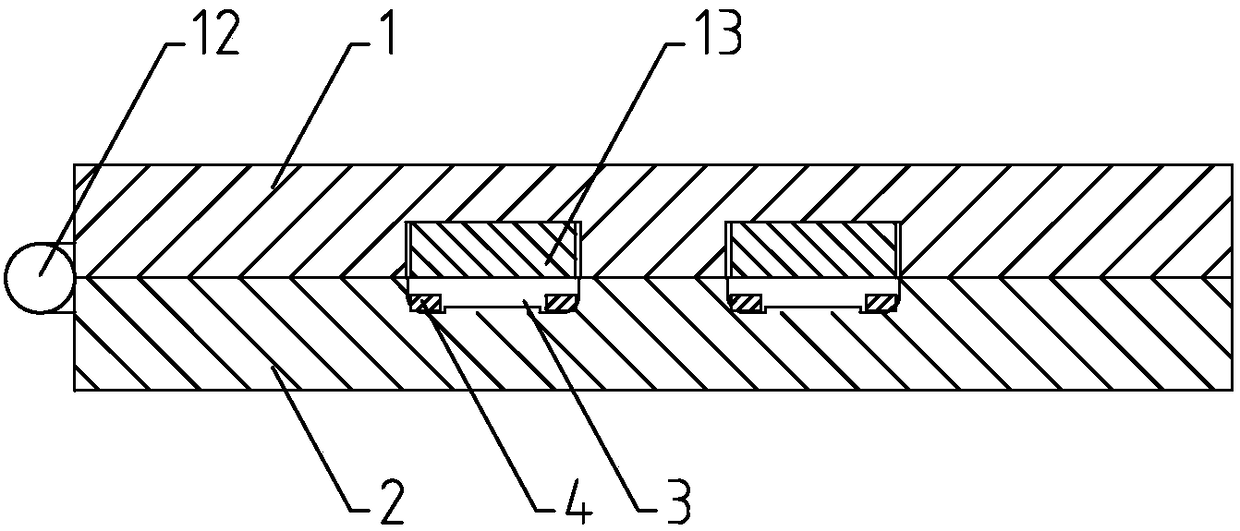

[0021] Such as figure 1 and figure 2 As shown in the embodiment of the present invention, a tooling for SMD optocoupler withstand voltage test includes an upper casing 1 and a lower casing 2. The upper casing 1 and the lower casing 2 are connected by a hinge 12 to facilitate the rotation The upper casing 1 and the lower casing 2 are driven to open or close. Both the upper casing 1 and the lower casing 2 are made of transparent insulating material (such as plastic), which is safe to use without leakage and is convenient for observing the experiment process. The lower housing 2 is provided with a lower test slot 3 for accommodating a plurality of optocouplers. The lower test slot 3 is provided with two parallel conductive slots, and a conductive part 4 for supplying power to the optocoupler is arranged in the conductive slot. The conductive part 4 is embedded In the conductive groove, the conductive part 4 can adopt an integrated conductive contact bar, and is connected to an ...

Embodiment 2

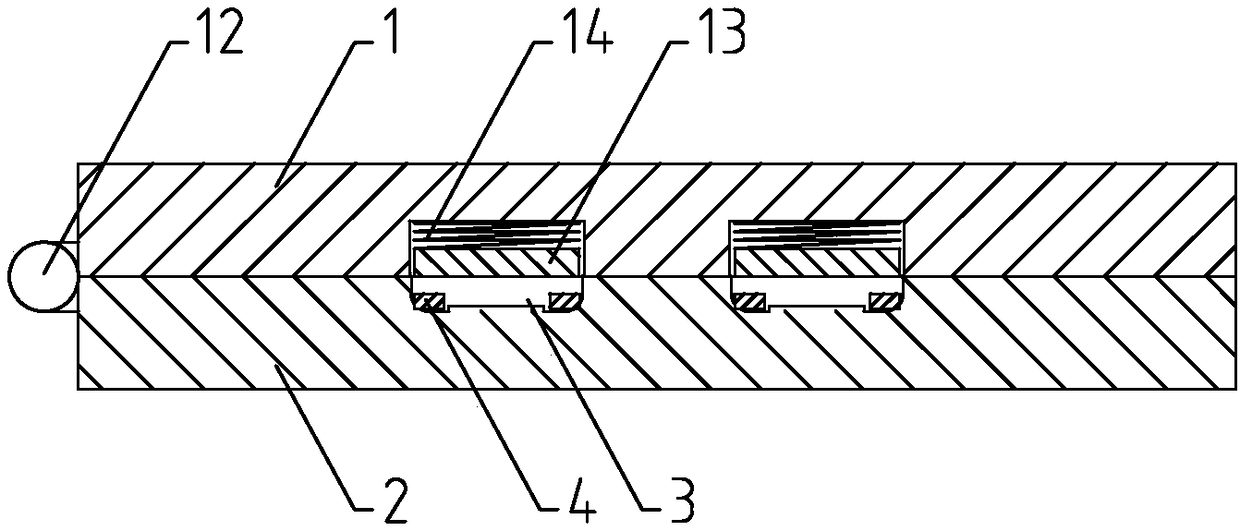

[0029] Such as image 3 As shown, the difference between the embodiment of the present invention and embodiment 1 is that the upper test slot 6 is provided with an elastic member 14 that drives the pressing member 13 to compress the optocoupler. The elastic member 14 can be a compression spring. The pressing part 13 is connected, and the other end of the elastic part 14 is connected with the bottom surface of the upper test groove 6, so as to strengthen the pressure on the optocoupler, thereby improving the experimental effect.

[0030] Refer to Example 1 for other undescribed structures.

[0031] To sum up, the present invention discloses a tooling for withstand voltage testing of patch optocouplers. The transparent and insulating upper and lower housings are used for withstand voltage testing of optocouplers, which is convenient and safe to use; Conductive grooves are used to install optocouplers in batches, and the transparent upper shell is convenient for observing the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com