Modified double-end motorized tool sharpener

A double-head motor and knife grinder technology, applied in grinding/polishing equipment, grinding/polishing hand tools, metal processing equipment, etc., can solve the problems of reduced work efficiency, high labor intensity, inconvenient use, etc., to achieve Improved work efficiency, high safety performance, and convenient use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

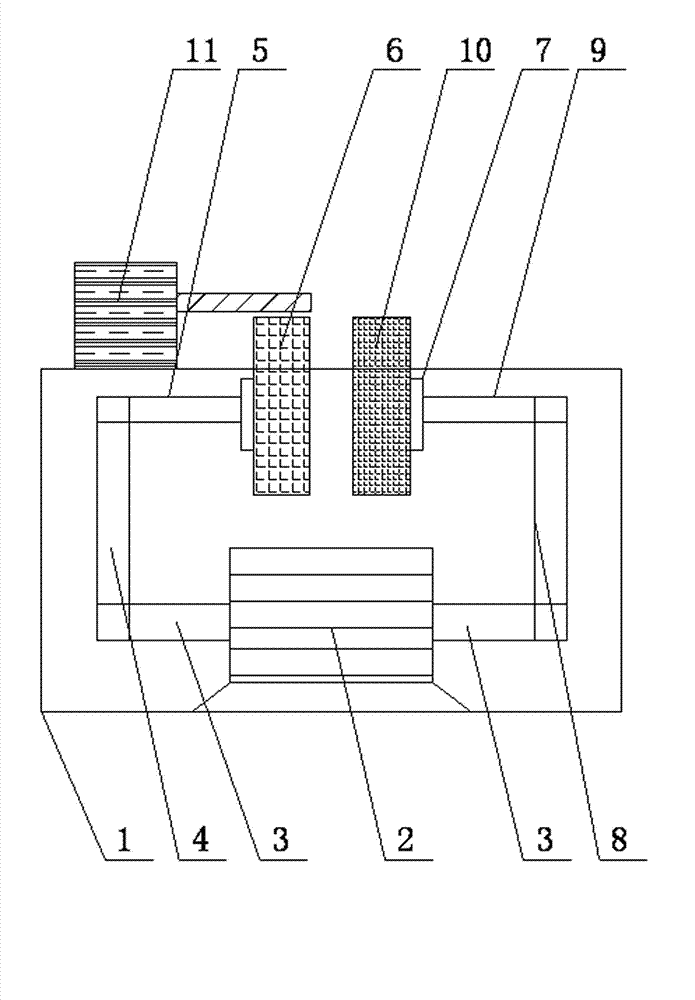

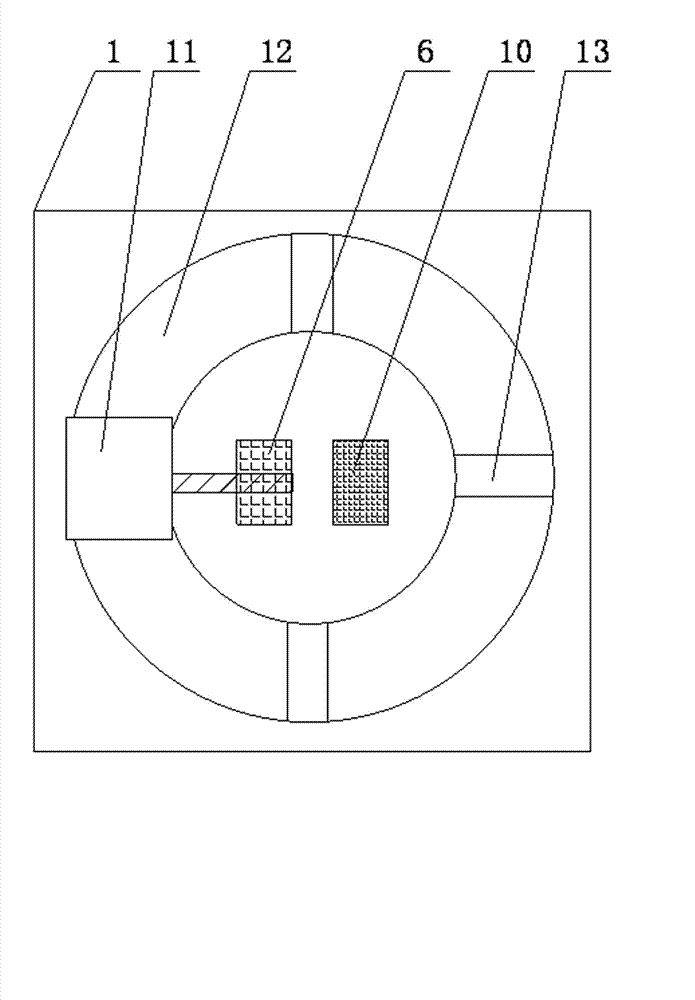

[0014] like figure 1 and 2 As shown, an improved double-head motor knife sharpener of the present invention includes a housing 1, a motor 2 is arranged in the housing 1, and a motor shaft 3 is arranged on the motor 2, and the motor shaft 3 passes through The rough drive shaft 4 is connected with the rough main shaft 5, and the rough main shaft 5 is provided with a rough sharpening stone 6, and between the rough sharpening stone 6 and the rough main shaft 5, a sharpening holder 7 is arranged, and the motor shaft 3 The thin drive shaft 8 is connected with the thin main shaft 9. The thin main shaft 9 is provided with a fine sharpening stone 10. 1. A tool rest 11 is provided at the top, and the tool rest 11 moves along the tool rest track 12 on the top of the housing 1. The tool rest 11 is provided with a tool rest fixed point 13. The tool rest track 12 is circular and has a simple structure. Generous, easy to use, high safety performance, stable work performance, improved w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com