Tool sharpener capable of automatic cleaning and good in cooling effect

An automatic cleaning and sharpening machine technology, applied in grinding/polishing equipment, grinding/polishing safety devices, other manufacturing equipment/tools, etc., can solve the problems of reduced work efficiency, inconvenient use, low safety performance, etc. Achieve the effect of improving work efficiency, convenient use conditions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

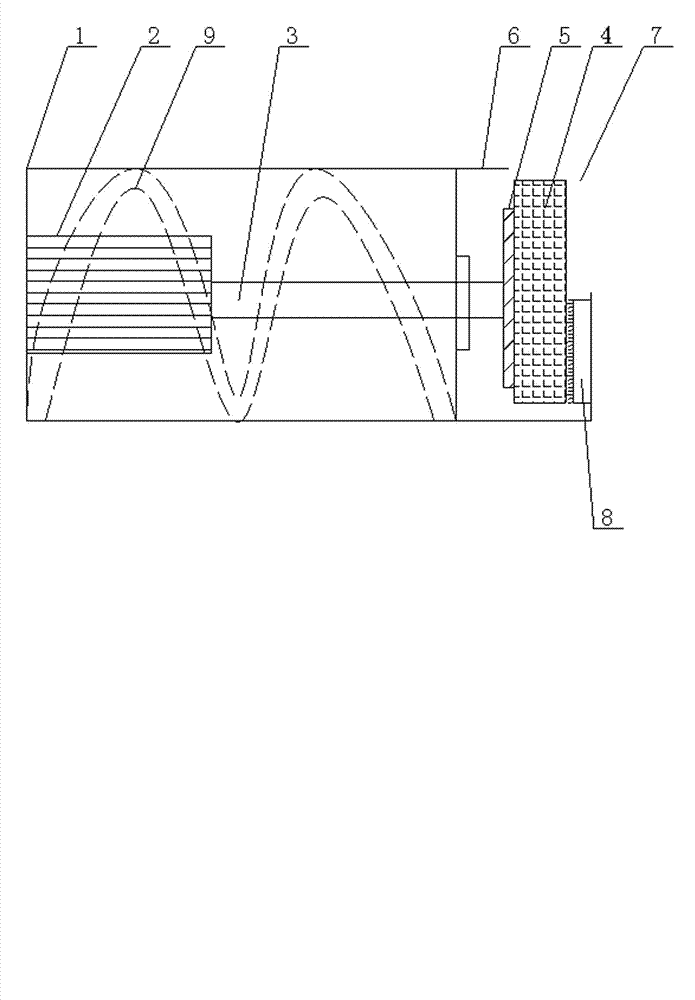

[0013] like figure 1 As shown, a knife sharpener with automatic cleaning and good cooling effect of the present invention includes a housing 1, a motor 2 is arranged in the housing 1, a main shaft 3 is arranged on the motor 2, and the main shaft 3 runs through Housing 1, the main shaft 3 is arranged on the peripheral end of the housing 1 to connect the grinding blade 4, a grinding blade bracket 5 is provided between the grinding blade 4 and the housing 1, and a grinding blade is arranged on the periphery of the grinding blade 4 Shield 6, one side of the grinding blade guard 6 is provided with a grinding edge 7, and a cleaning brush 8 is provided between the inner wall of the grinding blade guard 6 away from the grinding edge 7 and the grinding blade 4, and the housing 1 The inner wall is equipped with a cooling water exchange pipe 9, automatic cleaning, good cooling effect, simple and elegant structure, easy to use, high safety performance, stable working performance, impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com