Multi-stage filter for oil wells

A kind of filter and oil well technology, applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of unsatisfactory, poor filtering function, short service life, etc., and achieve convenient use conditions, reasonable structure, strong filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

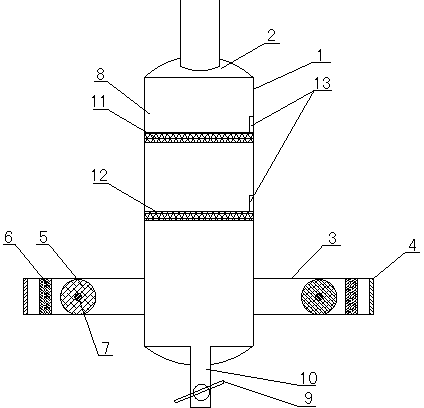

[0011] Such as figure 1 As shown, the oil well multistage filter according to the embodiment of the present invention includes an outer shell 1, the upper and lower bottom surfaces of the outer shell 1 are respectively equipped with sealing covers 2 and the upper end of the outer shell 1 is connected to the oil inlet pipe, and is located on the outer wall of the outer shell 1 There are two filter tubes 3 on the top, and each filter tube 3 is respectively perpendicular to the side wall of the outer shell 1; a rotating filter ball 5 is installed inside each filter tube 3 through a rotating shaft 7, and is located at the outer end of each filter tube 3. Buckle the cover 4 and add a mesh type filter belt 6 in the cavity between the rotary filter ball 5 and the buckle cover 4. At the same time, a second-stage filter screen 12 is horizontally arranged at the inner center of the outer shell 1. The filter inner cavity 8 above the second-stage filter screen 12 is provided with a first-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com