Novel hermetic petroleum filter unit

A filter device and sealing technology, which is applied in the fields of production fluid, wellbore/well components, earth-moving drilling, etc., can solve the problems of short service life, poor filtering function, single filtering energy, etc., so as to improve the sealing performance and convenience of the device. Use conditions, strong filtering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

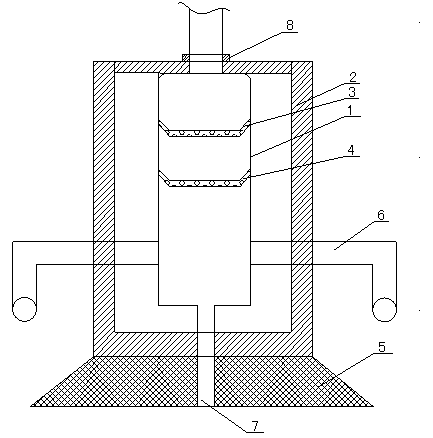

[0011] Such as figure 1 As shown, the novel sealed petroleum filter device described in the embodiment of the present invention includes a filter inner core 1, and the upper and lower bottom surfaces of the filter inner core 1 are respectively provided with an oil inlet pipe and an oil outlet pipeline 7, which are installed on the periphery of the filter inner core 1. The sealed steel shell 2 is covered with a sealing ring 8 at the junction of the top of the sealed steel shell 2 and the oil outlet pipeline 7. The bottom of the sealed steel shell 2 is equipped with a conical base 5 and the lower end of the oil outlet pipeline 7 is covered by the middle part of the conical base 5. At the same time, two layers of filter screens are arranged in the inside of the filter core 1 from top to bottom, that is, the first-stage filter screen 3, the second-stage filter screen 4, and the filter core below the second-stage filter screen 4 1. Both sides are connected with a section of shunt p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com