Mobile house

A technology for moving houses and houses, applied in special buildings, small buildings, building components, etc., can solve problems such as defects, and achieve the effect of reducing waste, reducing energy loss, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

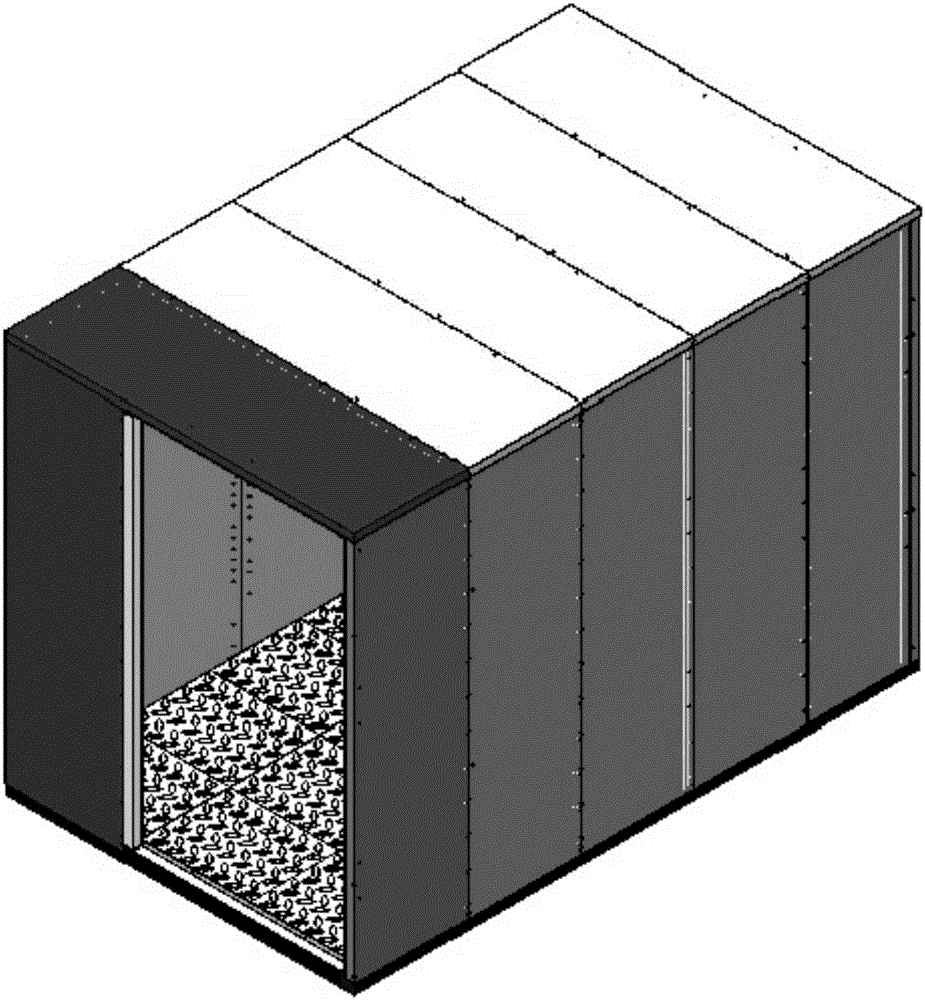

[0031] A movable house, the house is a cabinet, its general structure is like figure 1 As shown, the mobile home includes a top surface, a bottom surface, and 4 side surfaces, and one side has a door.

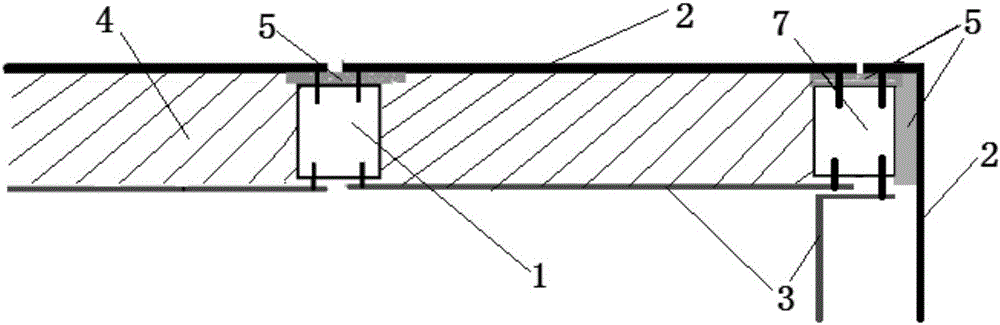

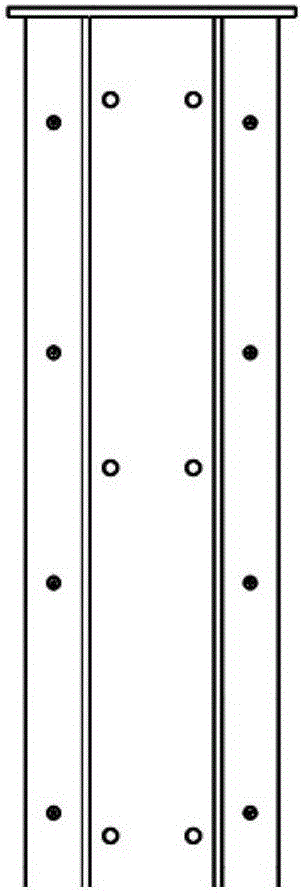

[0032] The top surface, bottom surface and side surface of the present invention are all composed of a frame column and a board surface module fixed on the frame column, wherein the structure of the board surface module is as figure 2 As shown, the panel module includes a connecting column 1 and an outer sealing plate 2 and an inner sealing plate 3 fixed on both sides of the connecting column 1. The connecting column 1 can be rectangular, convex, or I-shaped, as long as the connecting column 1 It is sufficient to have two parallel surfaces. The top and bottom ends of the connecting column are each provided with a connecting plate, and the connecting plate is provided with multiple screw holes. Among them, the structure of the convex connecting column is as image 3 As shown; the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com