Grouting, pipe fixing and plugging technique for deep drainage hole wall in water inrush borehole

A technology of drainage holes and grouting, which is applied in earthwork drilling, sealing/packing, wellbore/well components, etc. It can solve the problems of grout gushing out and drilling holes that cannot be blocked, and achieve the effect of reducing water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

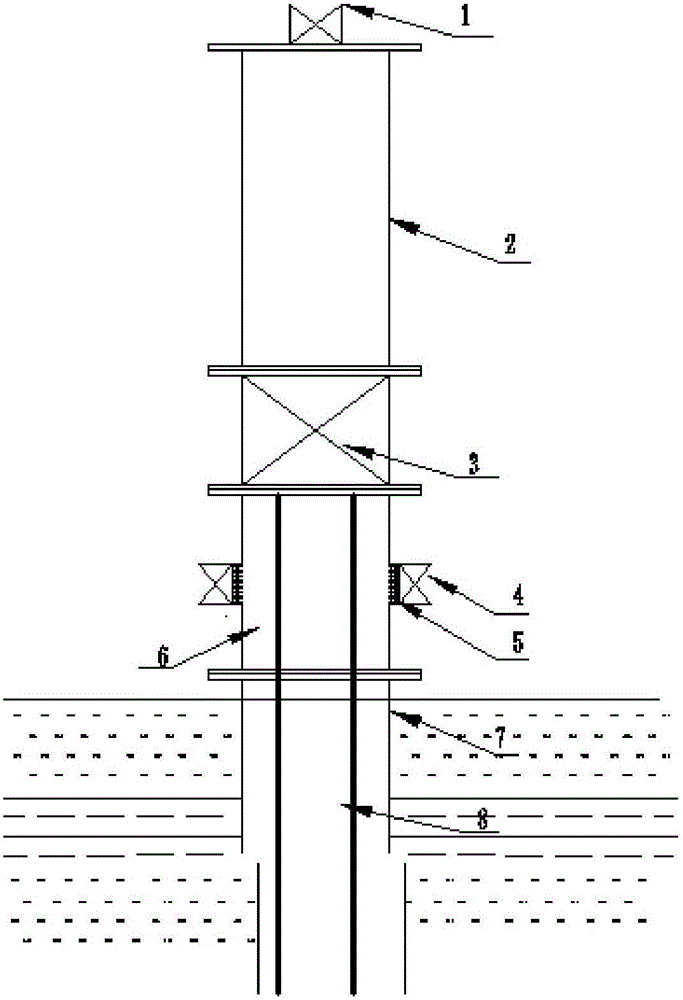

[0014] Referring to the attached drawing, the plugging process of the deep drainage hole wall grouting solid pipe in the water inrush drilling hole is used to drain and release the water from the deep aquifer in the hole by inserting a small-diameter drainage pipe 8 into the deep part of the orifice pipe 7 , using the original hole wall to inject grout into the hole, the specific process steps are as follows:

[0015] 1) Put the small diameter drainage tube 8 into the hole;

[0016] 2) Install the hole wall grouting device 6 at the orifice. The hole wall grouting device 6 includes the grouting gate valve 1, the material pipe 2, the hole wall gate valve 3, the pressure relief valve 5, the orifice pipe 7 and the material pipe 2 A pressure relief valve 5 is provided at the connection between them;

[0017] 3), the orifice is installed with a drainage orifice gate valve 4;

[0018] 4) Grouting through the hole wall grouting device 6 and the material pipe 2 into the hole through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com