Submarine cable traction structure and mounting method thereof

A technology for submarine cables and installation methods, which is applied to the installation of submarine cable traction structures and the field of submarine cable traction structures, can solve the problems of large manpower and time consumption, inconvenient operation, and threats to the life safety of operators, and achieve good sealing space and wiring Convenience, avoiding the effect of offshore operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

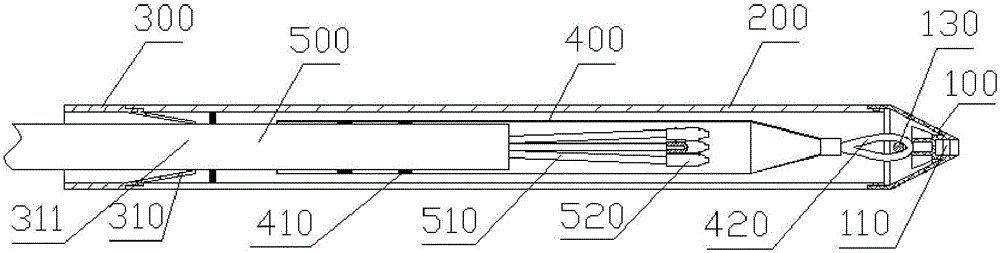

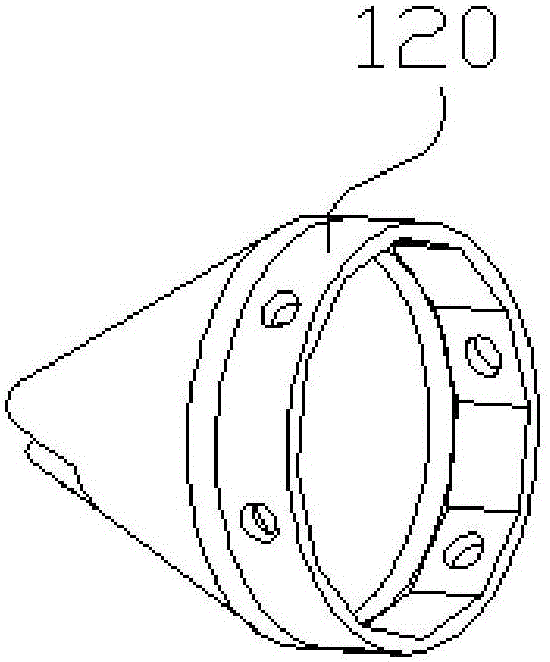

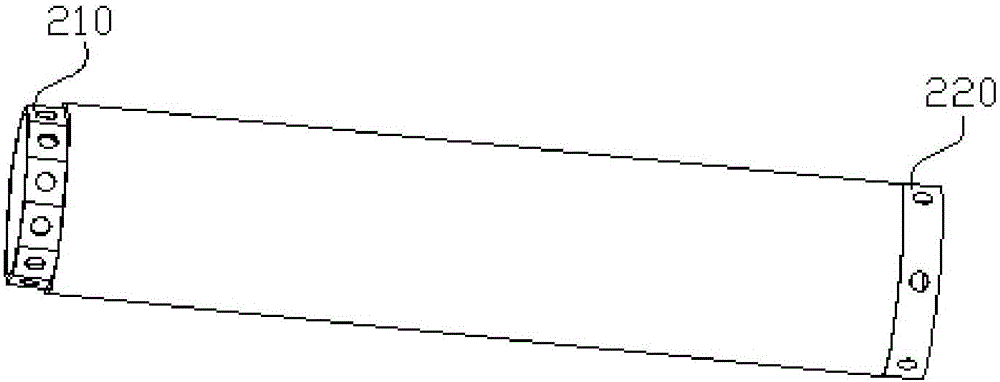

[0050] Please refer to figure 1 , the present embodiment provides a submarine cable traction structure, including a traction joint 100, a sealing tube 200, a sealing head 300 and a traction mesh sleeve 400; the sealing tube 200 is a hollow tubular structure; the traction joint 100 is sealed and connected to one end of the sealing tube 200, The sealing head 300 is connected to the other end of the sealing pipe 200; the sealing head 300 is a hollow structure, and the inner surface of the sealing head 300 is connected with a sealing connection sleeve 310 with a cable matching hole 311; the traction mesh sleeve 400 is arranged in the sealing pipe 200, And the front end of the traction net 400 is connected with the traction joint 100 .

[0051] The submarine cable traction structure in this embodiment is used to connect the submarine cable 500. After the traction structure is connected to the cable, the exposed end of the cable is located in the traction net sleeve, and the tractio...

Embodiment 2

[0071] This embodiment provides a method for installing the traction structure of the submarine cable 500 as in Embodiment 1, and its flow chart is as follows Figure 9 , the installation method includes the following steps:

[0072] Cable armor stripping step: strip the armor at one end of the cable 500 to be installed to expose the core wire 510;

[0073] Optionally, after the cable 500 is sheathed and stripped, a cable joint connection step can be carried out: separate the core wires 510 after stripping the armor, and connect the cable joints 520 to the ends of the core wires 510 respectively, and the cable joints are connected The step is located between the step of stripping the cable armor and the step of installing the sealing head;

[0074] Steps for connecting the traction net sleeve: insert the cable 500 that has been stripped of armor into the traction net sleeve 400 from the rear end of the traction net sleeve 400, so that the core wire 510 is wrapped by the tract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com