A convenient feeding device for metallurgical powder

A metallurgical powder and feeding device technology, which is applied in the field of feeding devices, can solve problems such as the inability to prevent metallurgical powder from floating and overflowing, the inability to effectively improve the conveying efficiency, and the inability to prevent metallurgical powder from clogging, so as to facilitate quantitative conveying, convenient conveying and processing, Avoid drifting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

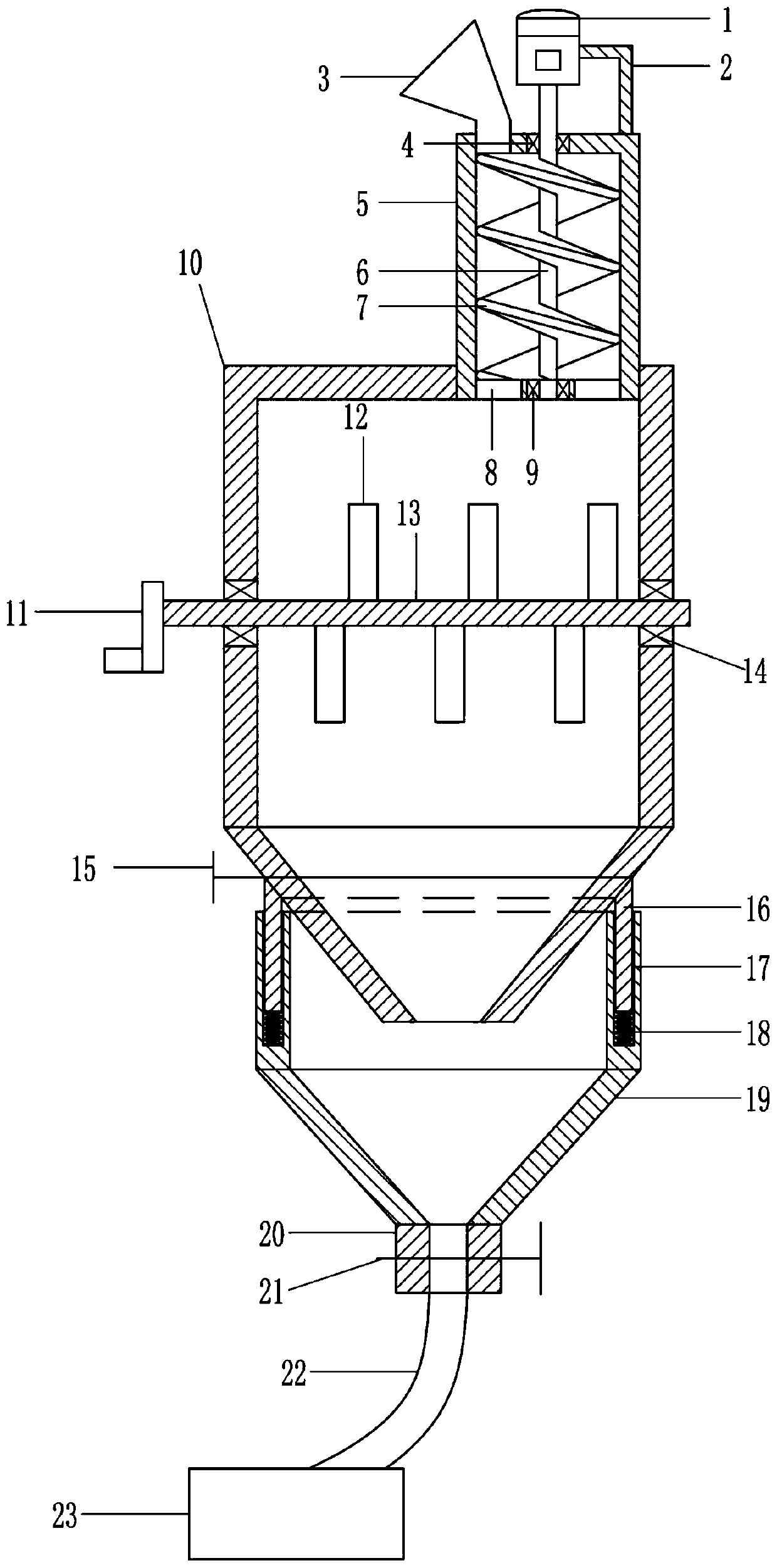

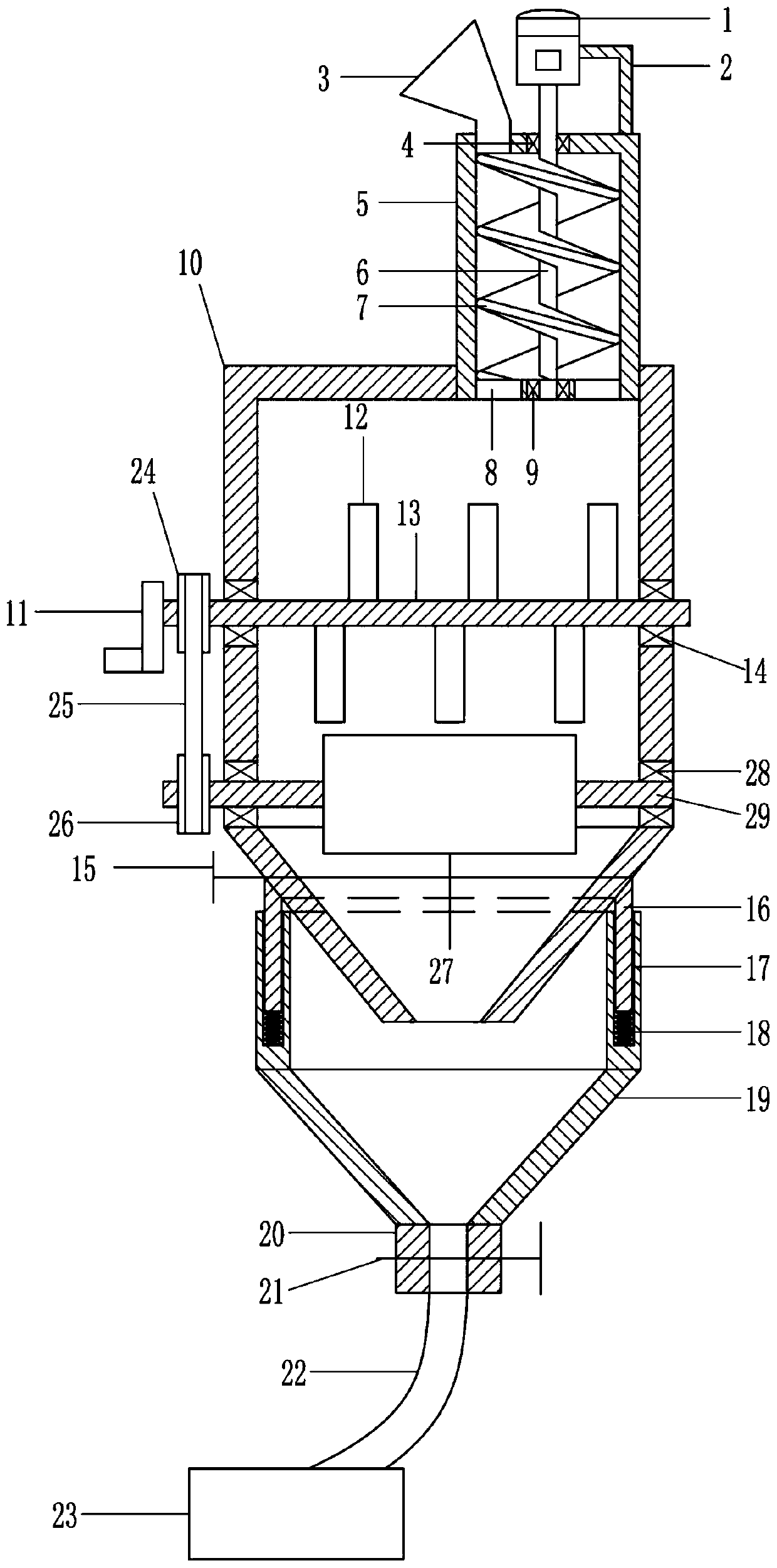

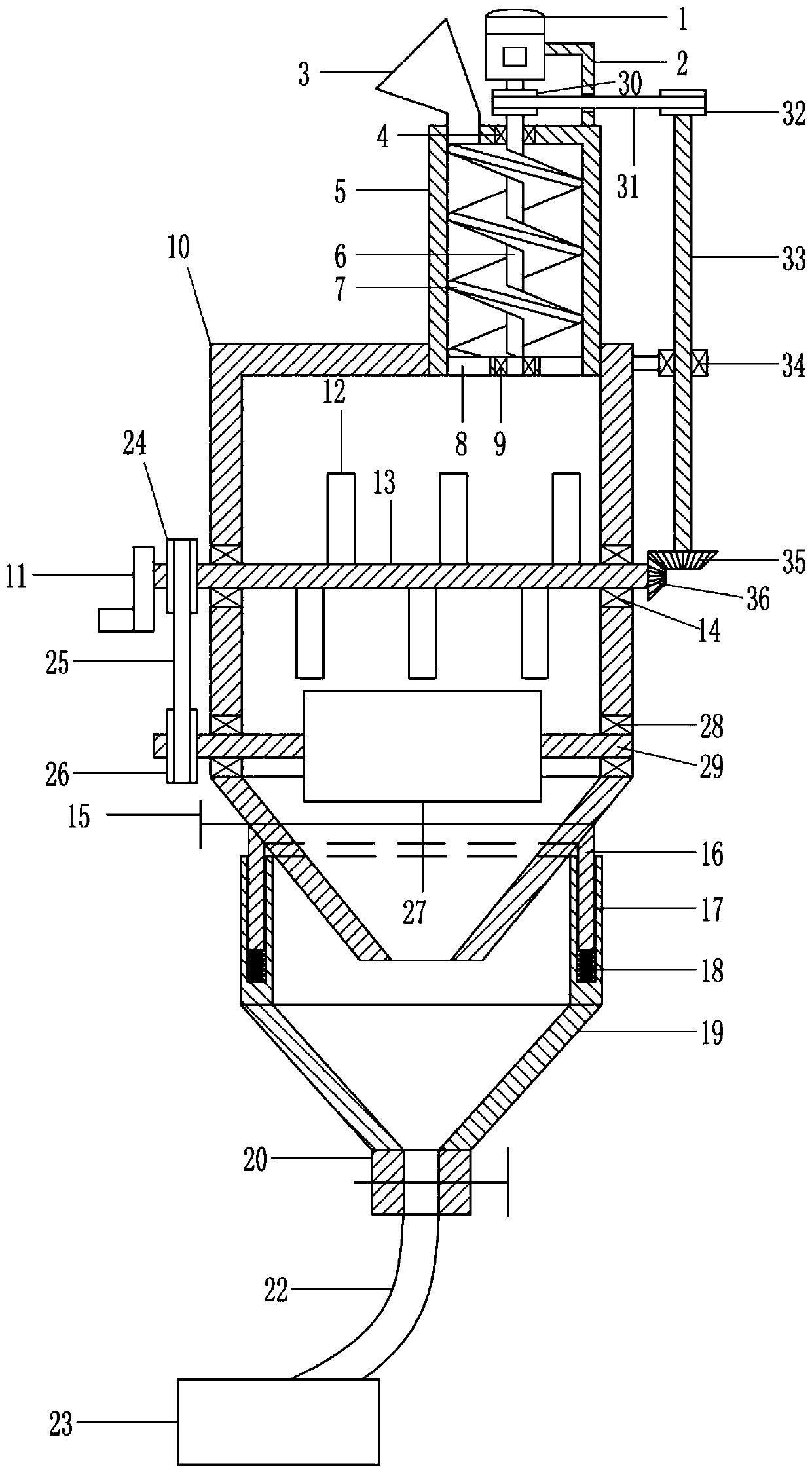

[0029] A convenient feeding device for metallurgical powder, such as Figure 1-5 As shown, it includes a drive motor 1, a fixed frame 2, a feed hopper 3, a first bearing seat 4, a feed barrel 5, a first rotating shaft 6, a spiral material guide plate 7, a second bearing seat 9, and a storage barrel 10. Handle 11, anti-freezing plate 12, second rotating shaft 13, feeding valve 15, lifting frame 16, first elastic member 18, quantitative hopper 19, discharge pipe 20, discharge valve 21, feed pipe 22 and powder The material box 23; the third bearing seat 14 is embedded in both sides of the material storage tank 10; the feed tank 5 is embedded in the top side of the material storage tank 10, and the bottom of the feed tank 5 has a discharge port 8; the feed hopper 3 Fixed on one side of the top of the feeding barrel 5, the fixed frame 2 is fixed on the other side of the top of the feeding barrel 5; the driving motor 1 is fixed on the end of the fixed frame 2; the first bearing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com