Caster structure of fishing line reel

A fishing reel and caster technology, which is applied to fishing reels, fishing, applications, etc., can solve the problem of inability to adjust the size of the force arm, and achieve the effects of novel structure, improved fishing fun, and clever design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

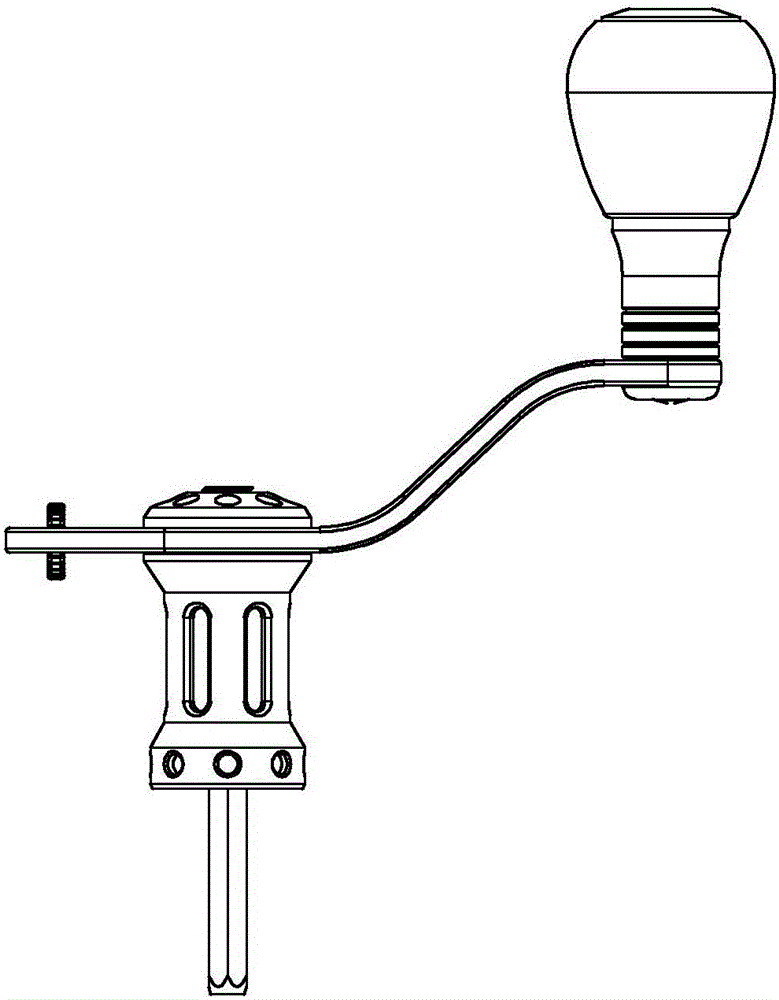

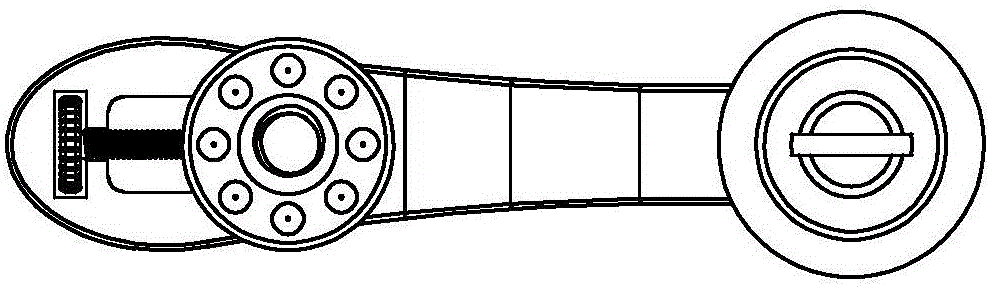

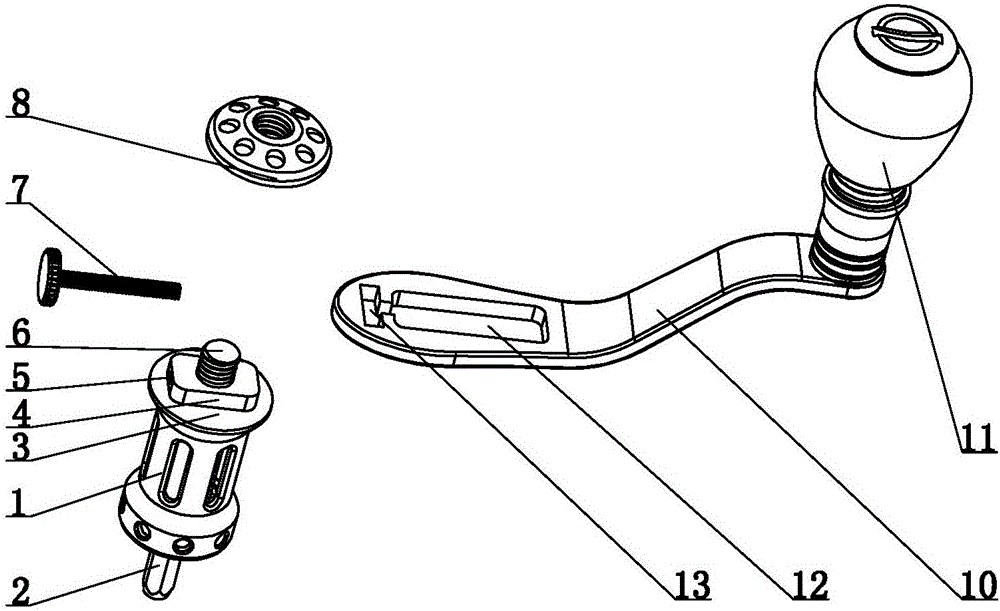

[0020] Such as figure 1 , 2 The fishing line wheel caster structure shown in 3 includes a rotating rod 2 inserted into a gear plate and a bracket 10. The rotating rod 2 is connected to one end of the bracket 10 through a mounting base 1, and the surface of the mounting base 1 is provided with a smooth mounting surface 3. , The mounting surface 3 is provided with a bump 4 conveniently, the other end of the bracket 10 is provided with casters 11, and the mounting seat 1 and the bracket 10 are provided with a moment arm adjustment structure.

[0021] The force arm adjusting structure includes a protrusion 4 provided on the surface of the mounting seat 1, an adjusting screw 7 is penetrated inside the protrusion 4, a threaded through hole 5 is horizontally provided inside the protrusion 4, an inner wall of the threaded through hole 5 and an adjusting screw 7 The tooth pattern of the bracket 10 is opposite. One end of the bracket 10 is provided with a movable slot 12 and a card slot 13....

Embodiment 2

[0024] Such as Figure 4 , 5 As shown, the difference between this embodiment and Embodiment 1 is that the force arm adjusting structure includes a clamping block 15 provided on the surface of the mounting base 1, a clamping slot 14 is provided on one end of the bracket 10, and the clamping block 15 is inserted into the clamping position. The slot 14 is installed on the bracket 10, the number of the locking slot 14 is three, the surface of the locking block 15 is provided with a screw 6, and the screw 6 passes through the locking slot 14 and is connected to the nut 8.

[0025] When in use, there are a plurality of locking slots 14, which are arranged in sequence along the bracket 10. The locking slots 14 close to or far from the casters 11 can be selected to adjust the size of the arm.

Embodiment 3

[0027] Such as Image 6 , 7 As shown, the force arm adjustment structure includes a protrusion 4 provided on the surface of the mounting seat 1, a sliding rod 16 is penetrated inside the protrusion 4, a movable chute 17 is provided at one end of the bracket 10, and both ends of the sliding rod 16 are fixed in the movable On both sides of the sliding groove 17, the middle of the surface of the protrusion 4 is hollowed out to form a hole 19, and a fixing screw 20 is installed in the hole 19. The fixing screw 20 contacts the sliding rod 16 and is pressed and fixed.

[0028] When using, first select the position of the protrusion 4 on the sliding rod 16, and then install the fixing screw 20 so that the fixing screw 20 tightly presses the sliding rod 16 to fix. The distance between the protrusion 4 and the casters 11 is adjusted by adjusting the protrusion The position of the block 4 on the slide bar 16 is changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com