Fire valve pressure test equipment and detection method thereof

A technology of fire valve and equipment, applied in the direction of detecting the appearance of fluid at the leak point, measuring device, testing of mechanical parts, etc., can solve the problem of inability to detect fire valve, and achieve the effect of ensuring accuracy and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

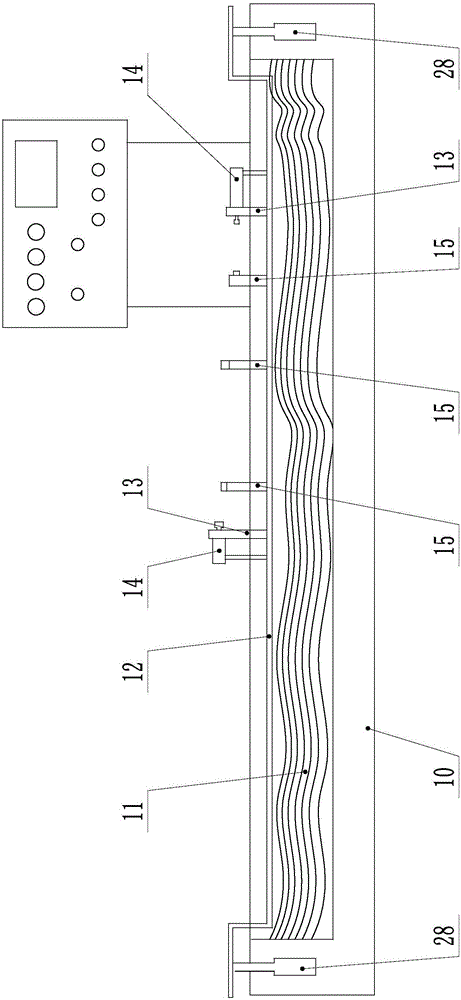

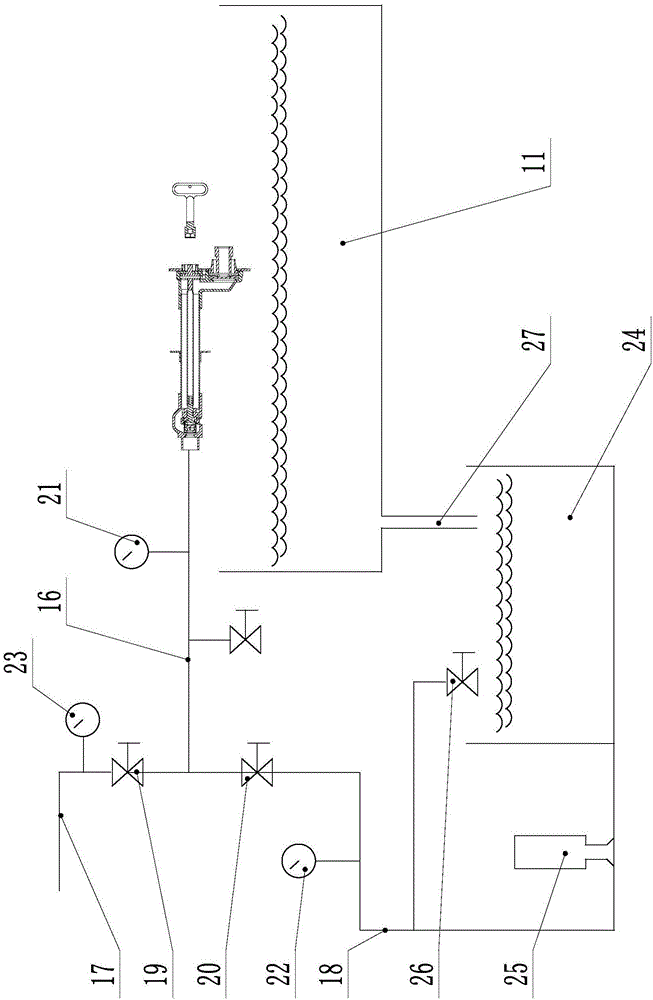

[0023] Reference figure 1 , 2 , Is a fire valve pressure test equipment disclosed in the present invention, including a workbench 10, a water tank 11 is provided on the workbench 10, a bracket 12 is provided in the water tank 11, and at least one set of detection positions is provided on the bracket 12; Each position includes two cylinder racks 13, and clamping cylinders 14 are installed on the two cylinder racks 13 respectively. The ejector rods of the two clamping cylinders 14 can be ejected in opposite directions; one of the clamping cylinders 14 has an ejector rod. The pressure test end, which can be connected to a port of the fire valve to be tested, and gas or water can be pressed into the port; a sealing plug is provided on the ejector rod of the other clamping cylinder 14, and the sealing plug The head can be sealed to the other port of the fire valve to be tested.

[0024] Among them, at least one cylinder frame 14 can be slidably displaced toward or relative to the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com