Dumping indication system for strip mine refuse dump

A technology for dumps and open-pit mines, applied to display devices, illuminated signs, instruments, etc., can solve problems such as potential safety hazards, buried dumps, and vehicle injuries, to eliminate injuries, reduce participation, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

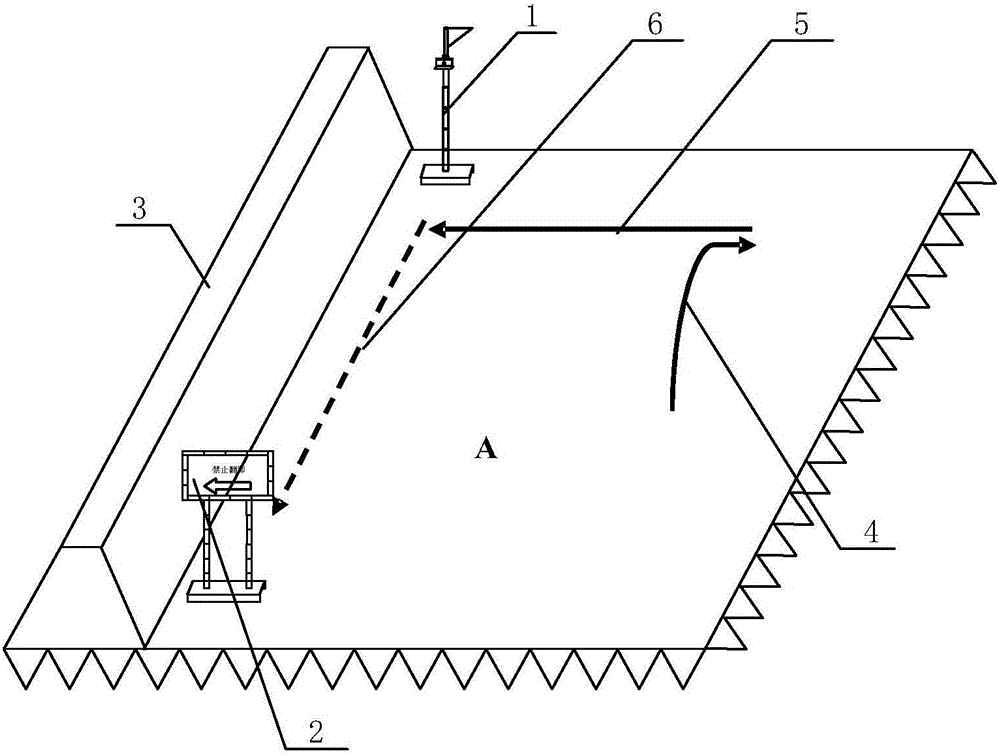

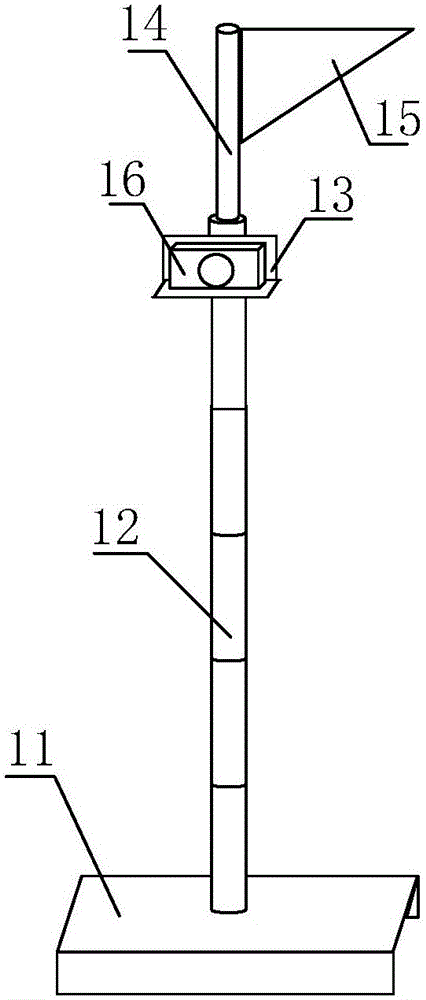

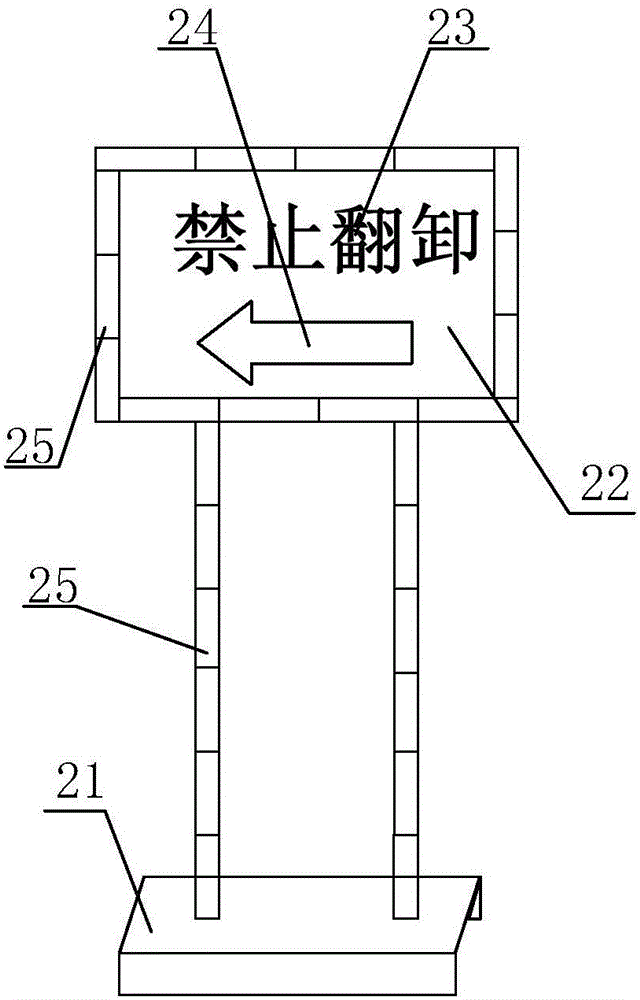

[0034] In a specific embodiment, the present invention provides an indication system for dumping operations in an open-pit mine dump. Please refer to Figure 1 to Figure 3 , the open-pit mine dump dump operation indication system provided in this embodiment includes: a dump indication mechanism 1 arranged on the dump operation plane A, a tipping prohibition mechanism 2, a retaining wall 3, a U-turn pointing mechanism 4, and a reverse pointing mechanism. Agency 5; of which,

[0035] The retaining wall 3 is set at one end of the earth discharge operation plane A;

[0036] The dumping indication mechanism 1 and the dumping prohibition mechanism 2 are respectively arranged on the front side of both ends of the retaining wall 3; those ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com