Method, apparatus and robotic system for moving an object to a target location

A target position and object movement technology, applied in the field of robot systems, can solve the problems of lack of effective methods and devices for moving to the target position, insufficient to meet the accuracy requirements of robot systems, etc., and achieve the effect of improving pose accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Some preferred embodiments will be described in more detail with reference to the accompanying drawings, in which preferred embodiments of the present disclosure are shown. However, the present disclosure can be implemented in various ways and thus should not be construed as being limited to the embodiments disclosed herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of this disclosure to those skilled in the art.

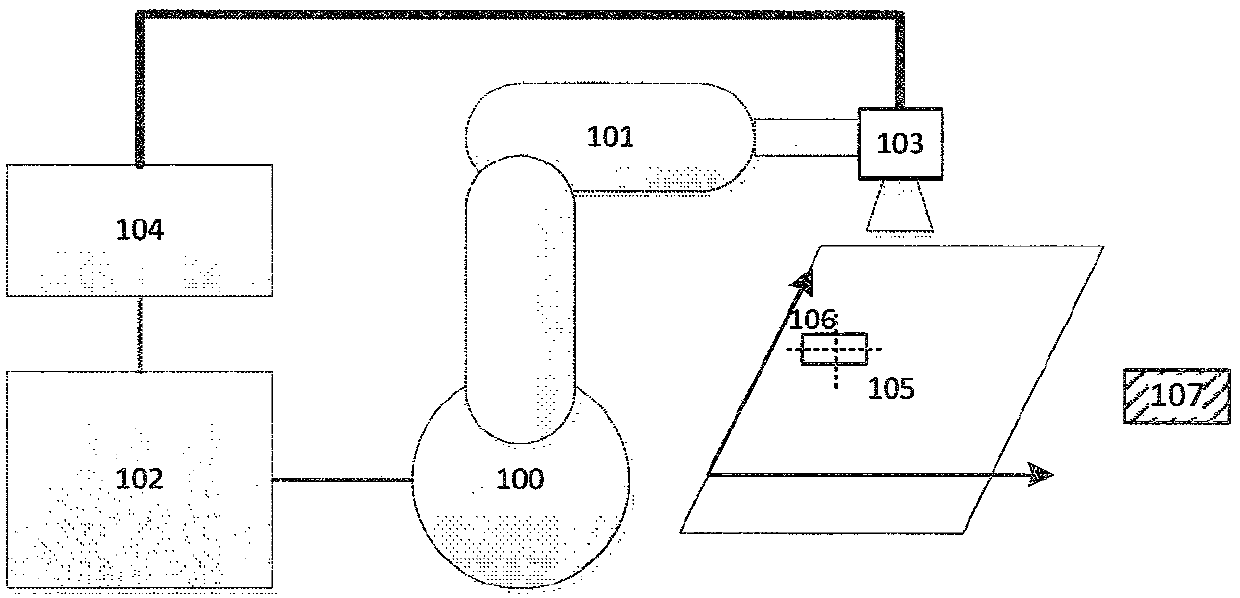

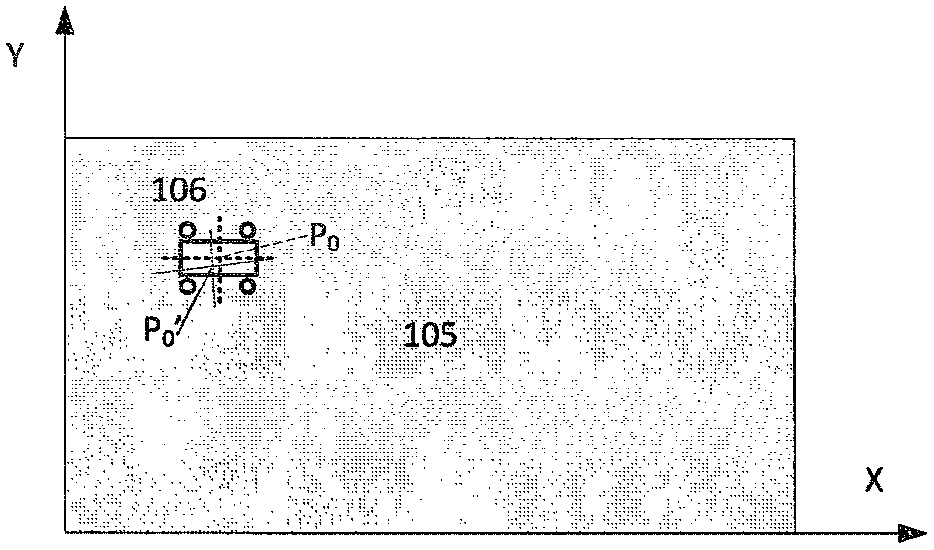

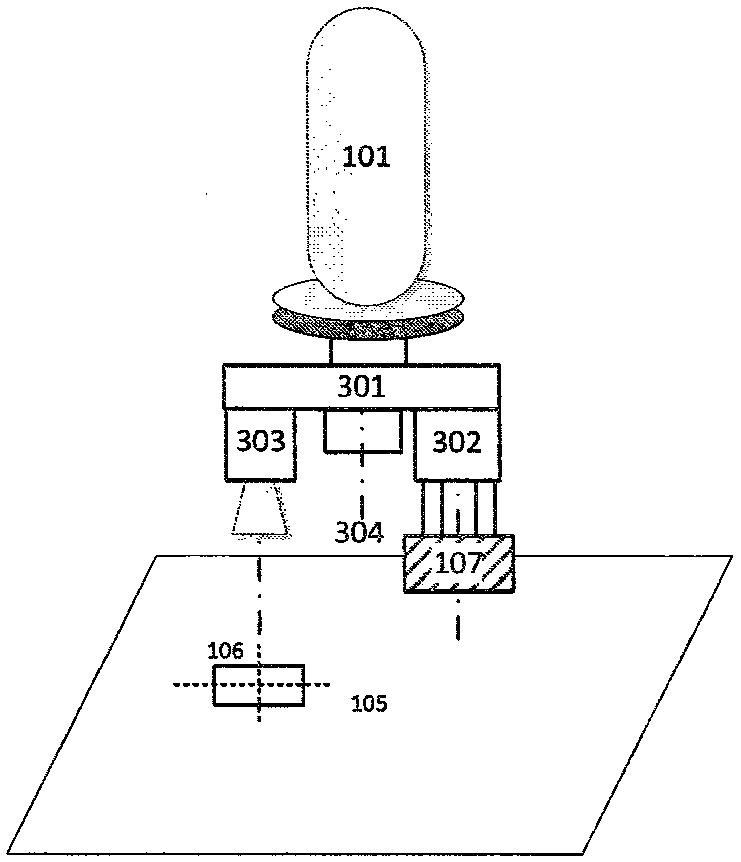

[0035] First refer to figure 1 , which schematically illustrates an exemplary layout of a vision-guided robotic system that may implement embodiments of the present disclosure. Such as figure 1 As shown, the robotic system may include a robot 100 , a control unit 102 and a vision system 104 . The robot 100 includes at least one arm 101 which may (or may not) hold a camera 103 to capture images of a target location 106 on a PCB board 105 where an object 107 should be placed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com