Self-adjusting clutch with adjusting display/feedback

A technology of compensation adjustment and self-compensation, applied in clutches, friction clutches, mechanically driven clutches, etc., to achieve the effects of low cost, reduced quantity, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

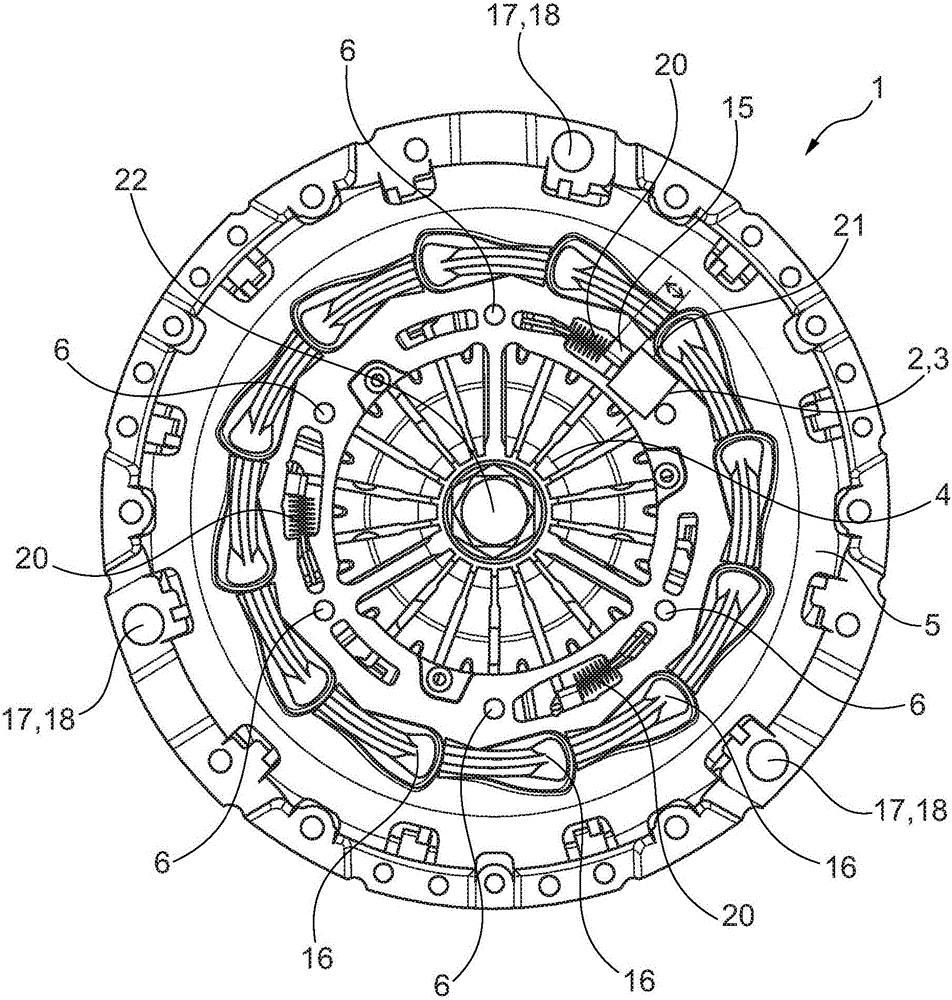

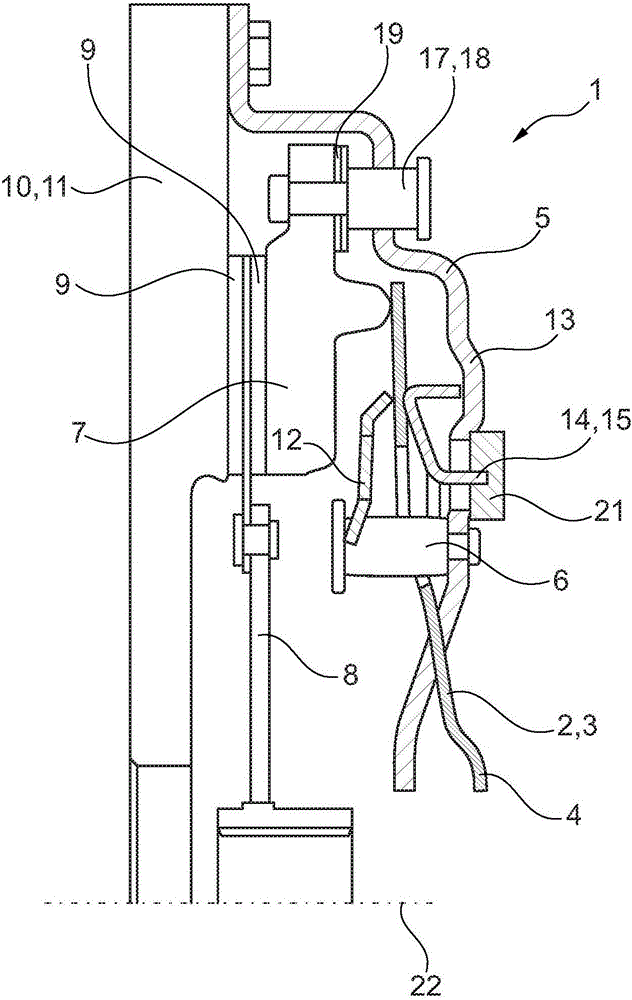

[0025] exist figure 1 A first embodiment of the self-compensating regulating clutch 1 according to the invention is shown in . The clutch 1 is intended to be installed in a motor vehicle such as a passenger car, a truck or another commercial vehicle. The actuating mechanism 2 is designed as a disc spring 3 and has a tongue 4 which can be activated by a triggering mechanism such as a release bearing.

[0026] combine figure 2 It is also shown that the disk spring 3 is fastened to the cover 5 by means of several, here six, fastening bolts 6 . The outer end, for example the outer edge, of the disc spring 3 facing away from the tongue as viewed from the fastening pin 6 presses against a pressure plate 7 which is axially displaceable in the direction of the clutch disc 8 bit. Mounted on the clutch disc 8 are two friction linings 9 , which also have their own spring action according to the type of "lining spring arrangement".

[0027] The friction lining 9 facing away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com