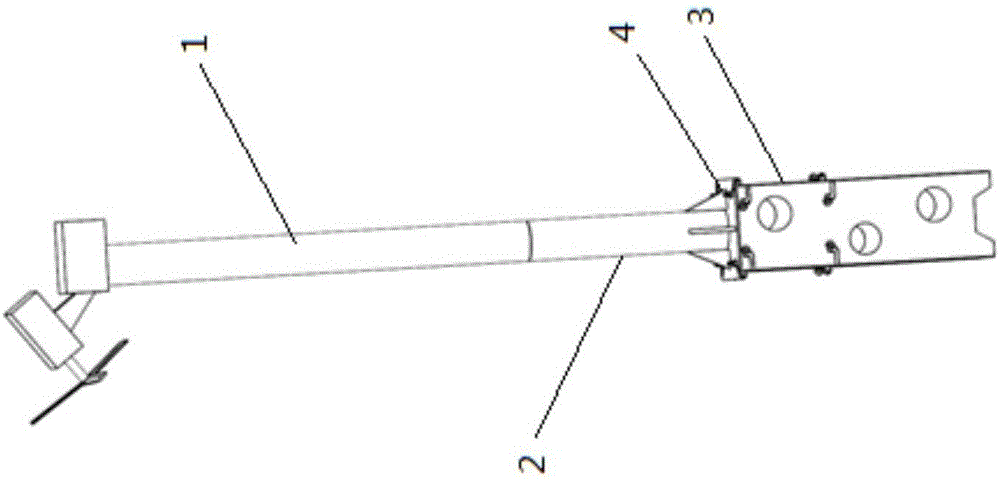

Frost prevention machine column fixing device

The technology of a fixing device and an anti-frost machine is applied in the field of agricultural machinery, which can solve the problems of reducing the safe use performance and working efficiency of the anti-frost machine, it is difficult to completely eliminate the gap between the soil and the column, and the installation efficiency of the column of the anti-frost machine is low. The effect of installation efficiency and economic benefits, increased work reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described in detail with specific examples below, but the protection scope of the present invention is not limited thereto.

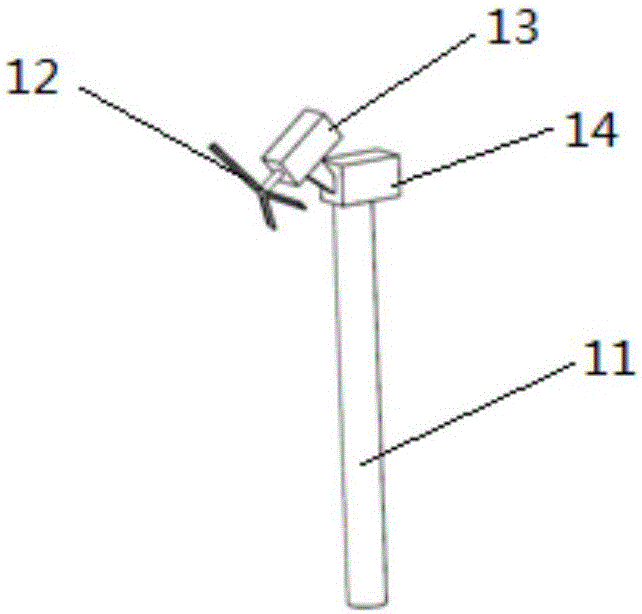

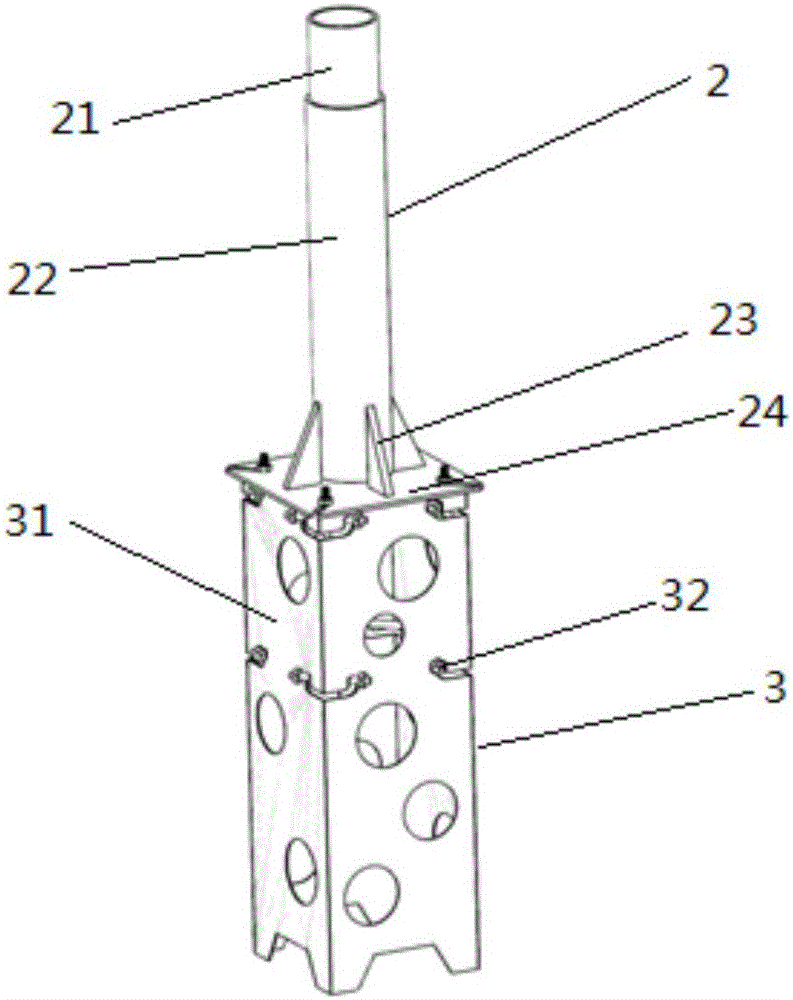

[0027] The fixing device for the column of the anti-frost machine according to the present invention overcomes the difficulties of high accuracy of excavation holes, small-diameter deep holes and backfill compaction in the common fixed installation method of the anti-frost machine by driving the base into the soil , which reduces labor intensity and improves installation efficiency; the use of connecting supports enables standard pipes to replace the original non-standard pipes that must be selected to meet the height of the anti-frost machine, which greatly saves material costs and facilitates transportation and storage; The openings on the base plate make the soil inside and outside the base connected as a whole, which further enhances the stability of the base and reduces damage to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com