A kind of anti-dumping planting pot of self-refilling hydroponic plant

A hydroponic plant, anti-dumping technology, applied in the field of plant cultivation, can solve the problems of being easily affected by plane shaking, adding nutrient solution, dumping, etc., to achieve the effects of increasing anti-dumping, increasing stability, and simple and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

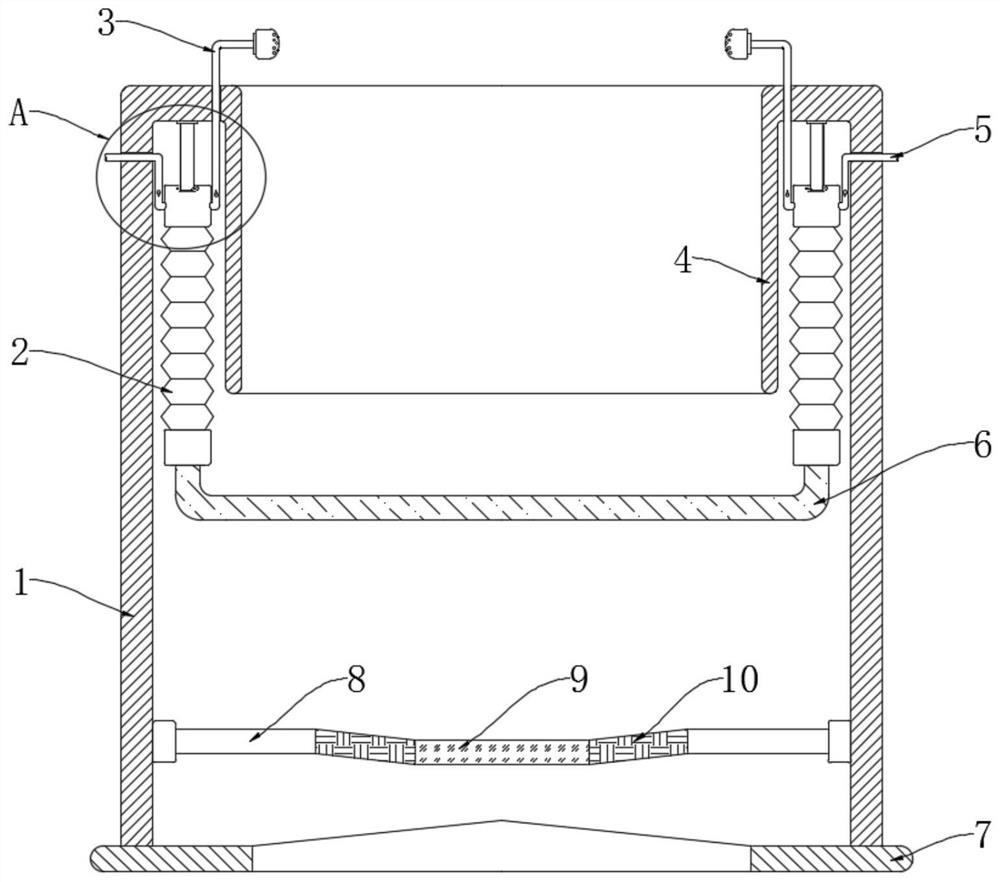

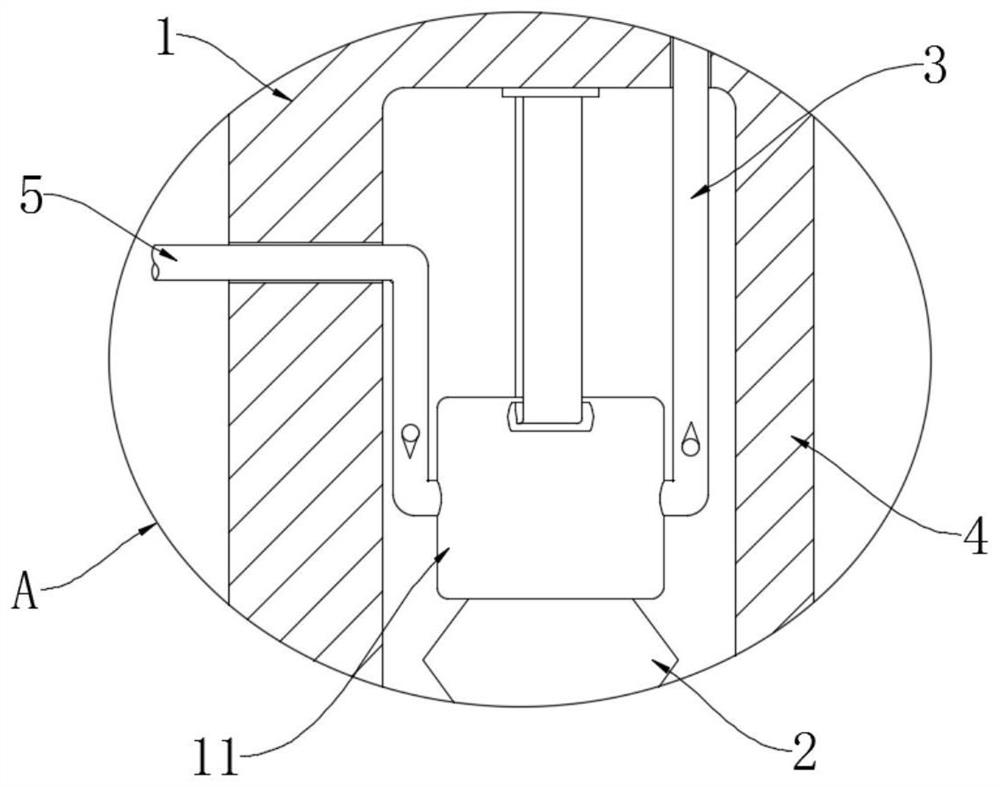

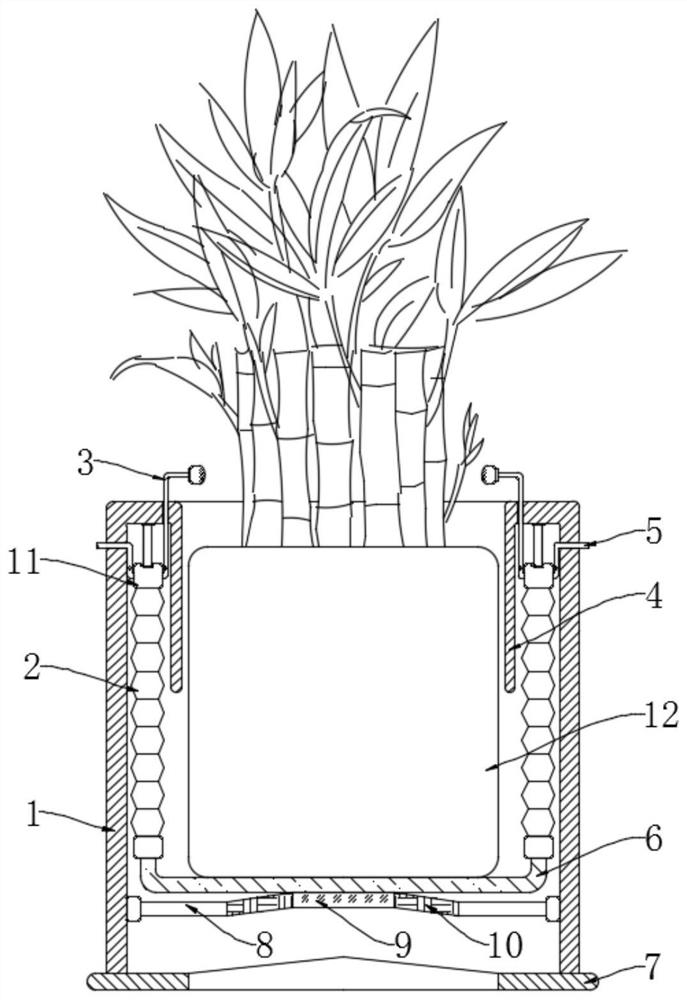

[0028] refer to Figure 1-4 , a self-replenishment type anti-dumping planting pot for hydroponic plants, comprising a pot body 1 and a planting groove 12, the inner side of the pot body 1 is provided with a rib 4 fixedly connected to the upper end of the pot body 1, and the rib 4 is used to limit the planting groove 12, so as not to squeeze the telescopic tube 2 when the planting tank 12 is put into the pot body 1, causing a large amount of liquid to be sprayed out from the elbow 3, and two connecting heads 11 are fixedly installed between the rib 4 and the inner side wall of the pot body 1, The bottom wall and the two side walls of each connecting head 11 are respectively connected with telescopic pipe 2, elbow pipe 3 and water supply pipe 5, and the bottom ends of the two telescopic pipes 2 are connected with magnetic storage board 6, magnetic storage board 6 is placed with a planting tank 12, the upper end of each elbow 3 is equipped with a nozzle, and the nozzle is located...

Embodiment 2

[0041] refer to Figure 5 The difference between this embodiment and Embodiment 1 is that a sealing groove 13 is provided between the sealing plate 8 and the inner wall of the basin body 1, and the sealing plate 8 and the sealing groove 13 are slidably connected, and there are a plurality of communication channels in the sealing plate 8. The pipeline 16 is provided with a plurality of exhaust ports 14 on the side wall of the basin body 1, and a second one-way valve is installed in each exhaust port 14, and multiple valves are arranged between the sealing plate 8 and the anti-slip rubber pad 7. a return spring 15;

[0042] The second one-way valve only allows the gas in the basin 1 to be discharged to the outside from the exhaust port 14 .

[0043] When using this embodiment, after the planting groove 12 is placed on the magnetic storage plate 6, the magnetic storage plate 6 will move downward and press the sealing plate 8 downward, so that the sealing plate 8 moves along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com