A roadbed pile-slab width-splicing structure and its construction method

A construction method and pile-slab technology, which is applied in the direction of infrastructure engineering, roads, roads, etc., can solve the problems of cushion slippage, land occupation, landslides, etc., and achieve the prevention of cushion slippage, simple construction method, and prevention of lowering The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

[0054] In this embodiment of the present invention, the high-pressure rotary grouting pile construction technology, concrete pouring technology, concrete jacking and pouring construction, etc. belong to conventional technologies, and will not be repeated in this implementation, and focus on the embodiment of the present invention related to the structure.

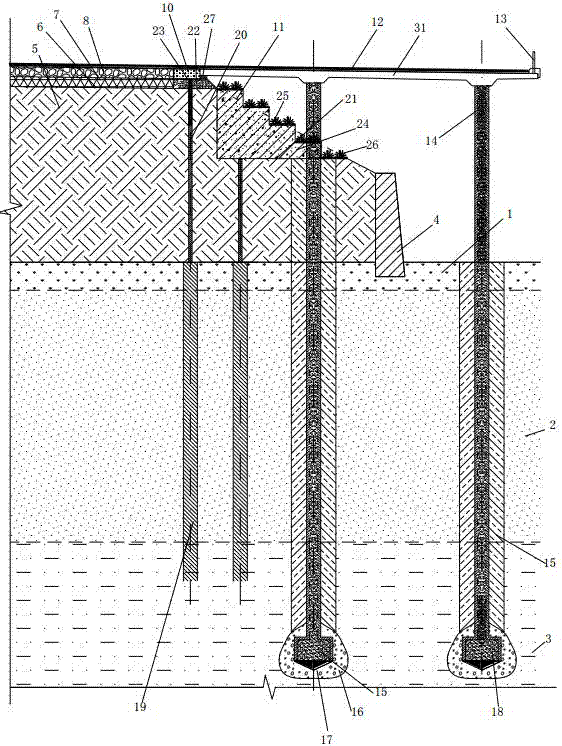

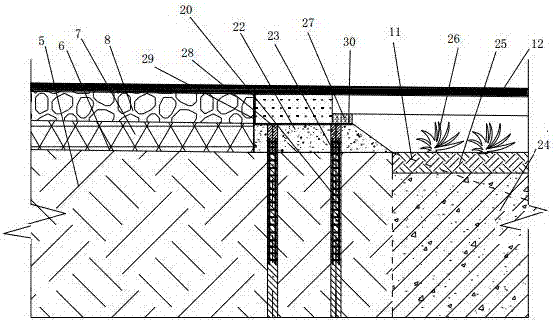

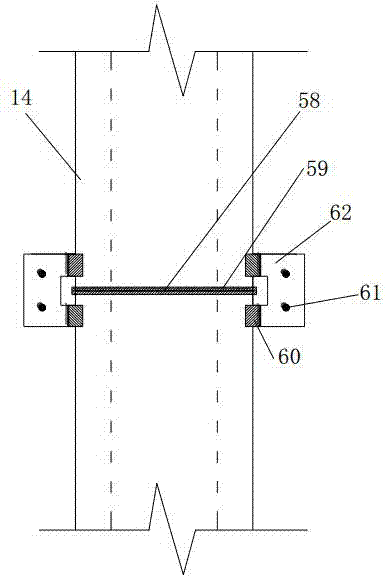

[0055] Such as Figure 1-14 As shown, a kind of subgrade pile-slab type widening structure of the present invention includes the old road bed 6, the original slope protection 11, the original slope retaining wall 4 and the rear road bed 31, between the old road road bed 6 and the rear road bed 31 A post-pouring lap section 10 is provided, and the lower part of the post-casting lap section 10 is provided with a cushion layer 22. Under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com