Dustproof mechanical keyboard switch capable of being automatically assembled easily and assembly method thereof

A technology of mechanical keyboards and switches, applied in electric switches, emergency protection devices, electrical components, etc., can solve the problems of complex structure, no sense of paragraph, insufficient return spring feedback, etc., to improve the quality of input experience, good feel and sound sense, the effect of a good paragraph sense

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

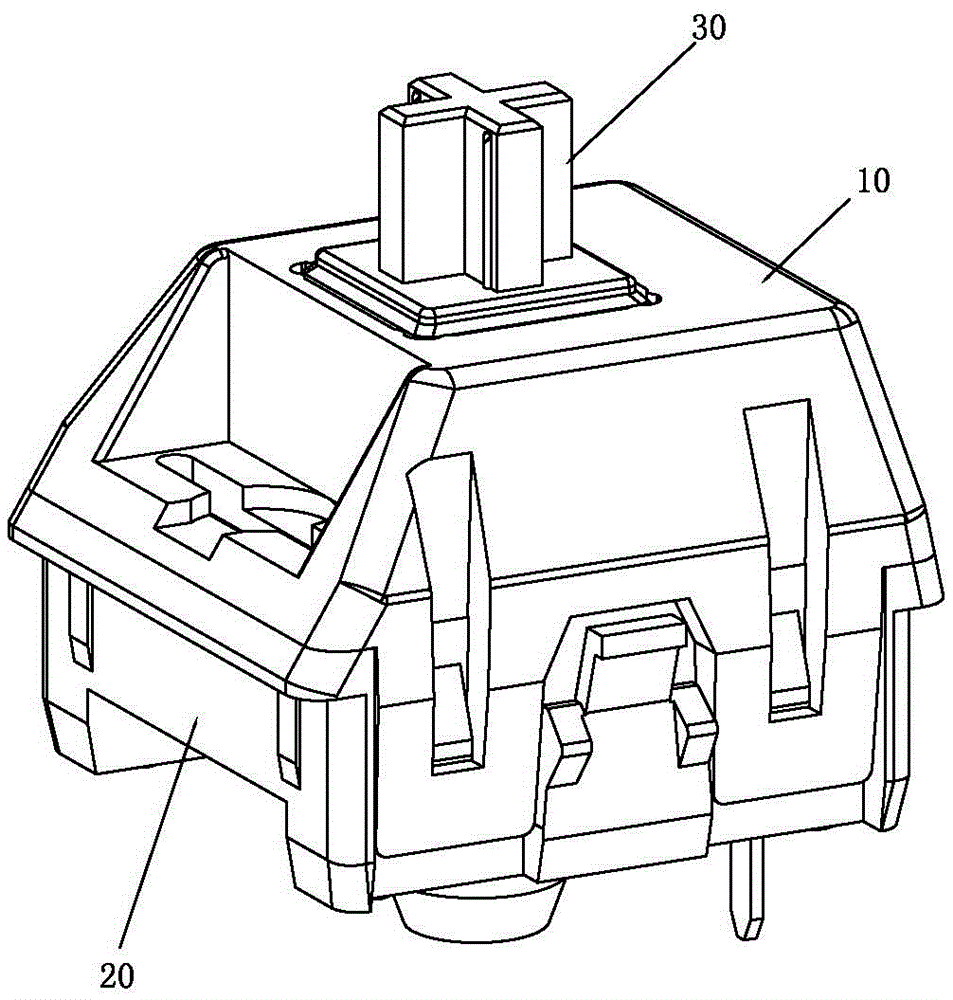

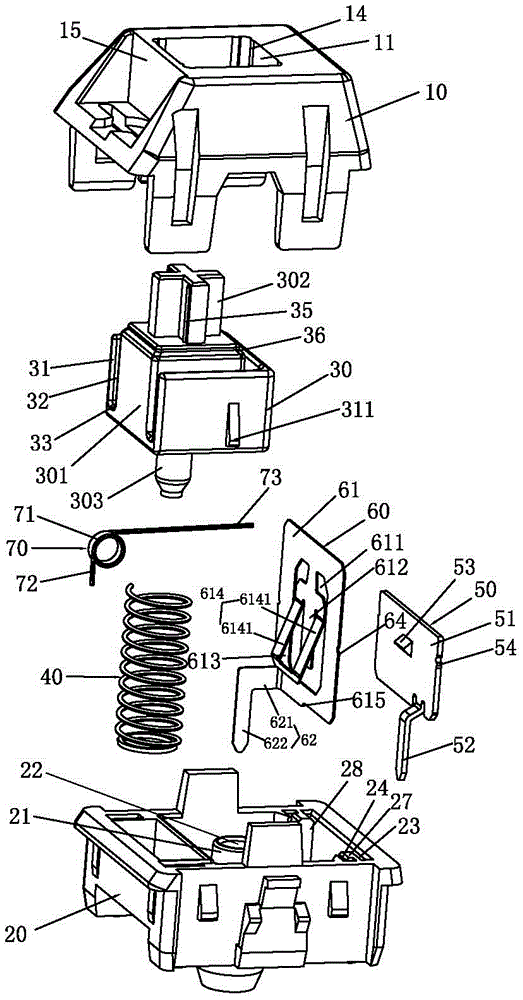

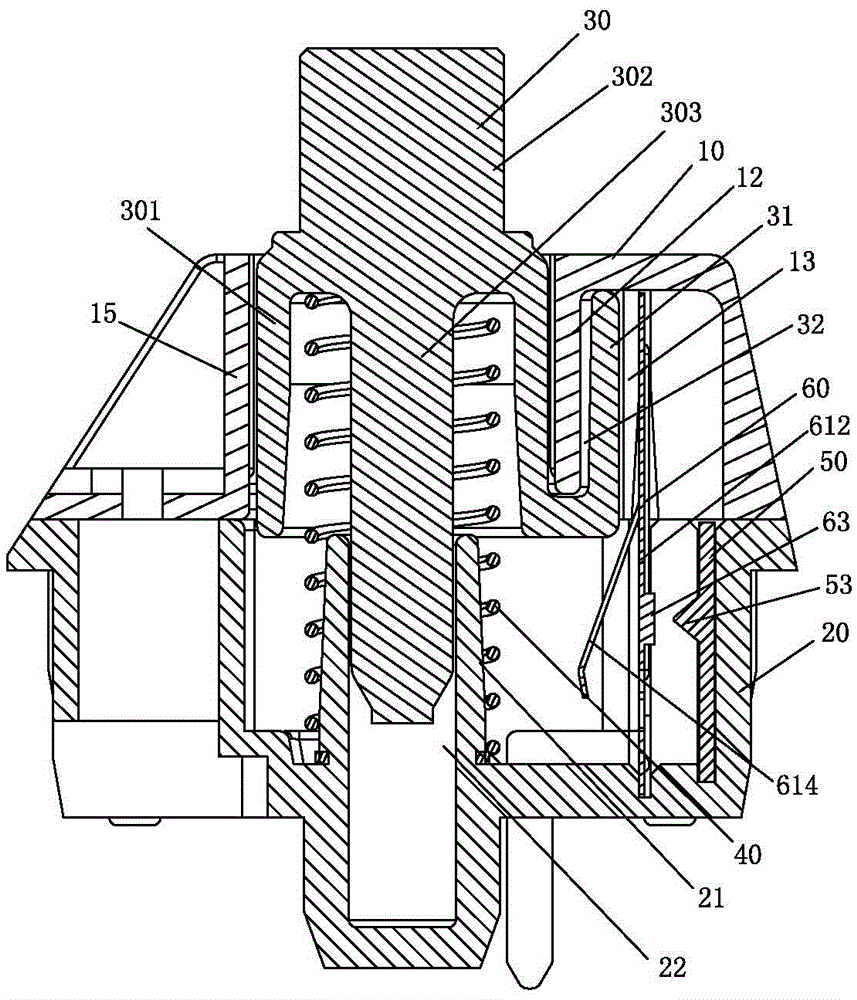

[0074] Please refer to Figure 1 to Figure 11 As shown, it shows the specific structure of the embodiment of the present invention, which includes an upper cover 10, a base body 20, a guide core 30, a return spring 40, a stationary piece 50, a moving reed 60 and a torsion spring 70.

[0075] like Figure 1 to Figure 3 As shown, the upper cover 10 is installed on the seat body 20, and the upper cover 10 and the seat body 20 are surrounded to form an accommodating space, the upper cover 10 is provided with a through hole 11 passing through the accommodating space, and the return spring 40 is provided In the accommodating space, the guide core 30 is connected to the return spring 40 and can slide out of the through hole 11. The movable spring 60 is driven by the guide core 30 to contact or separate from the stationary piece 50; the upper cover 10 corresponds to A first dust-shielding wall 12 is connected to the aforementioned through hole 11, and the first dust-shielding wall 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com