Method for reducing torque fluctuation of six-pole nine-slot synchronous motor

A torque fluctuation, synchronous motor technology, applied in electrical components, electromechanical devices, etc., can solve the problems of large back EMF harmonics of the motor, affecting the running stability of the motor, and large torque fluctuation of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

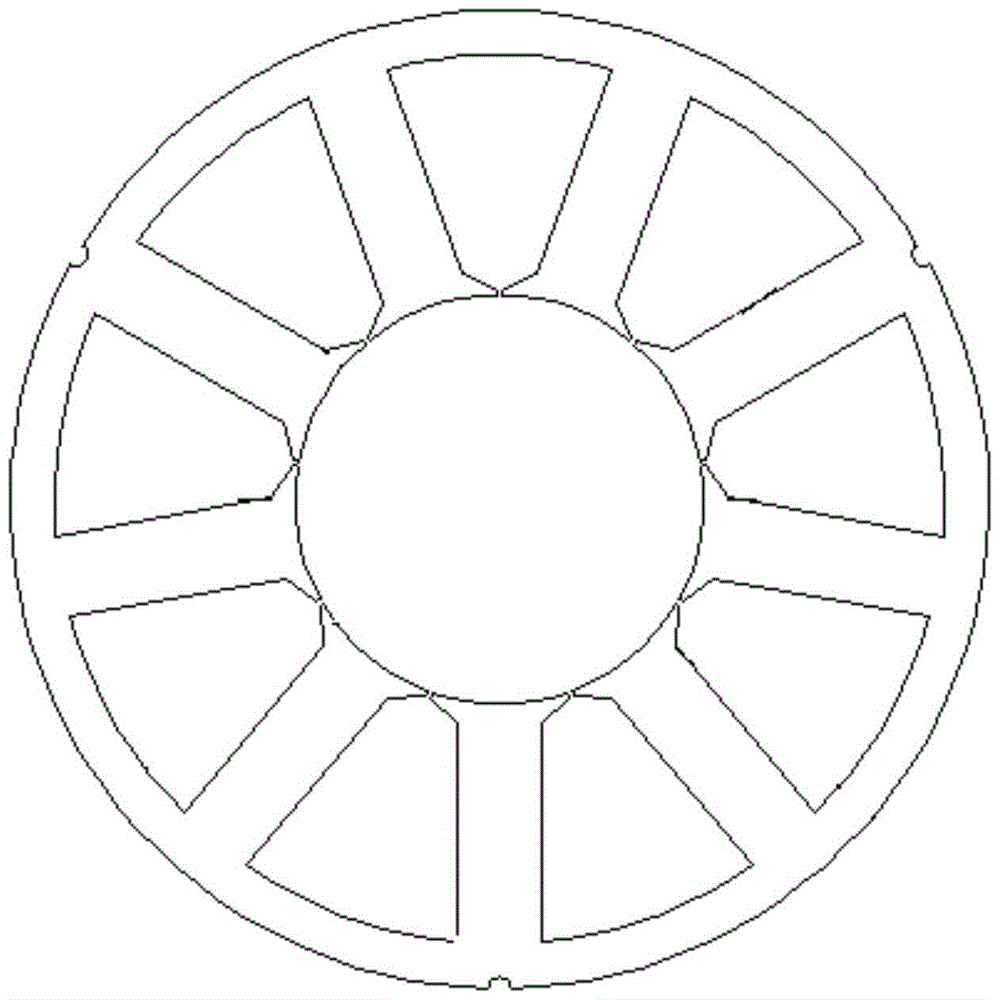

[0024] A method for reducing torque ripple of a 6-pole, 9-slot synchronous motor, comprising the steps of:

[0025] (1) Calculate the power P i ’, if the motor runs for a long time, then If the motor runs for a short time, the where P N is the rated power of the motor, and η' is the prefetching efficiency of the motor.

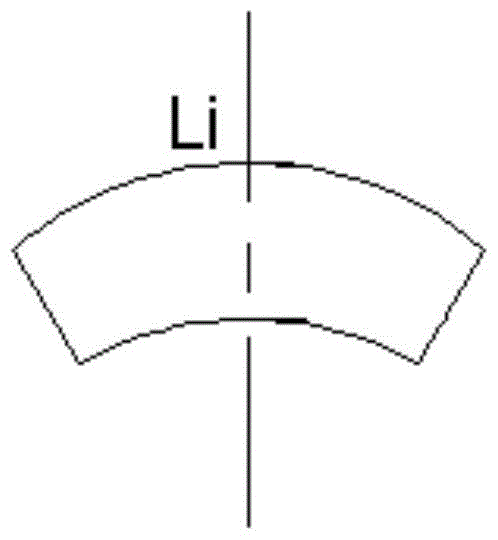

[0026] (2) Calculate the inner diameter of the armature B' δ is the prefetched air gap flux density, A' δ is the prefetch line load, α i The polar arc coefficient is calculated for prefetching, λ' is the prefetching aspect ratio, and the outer diameter of the armature is D 1 >D il .

[0027] (3) Calculate the armature core length L≈λ′D i1 .

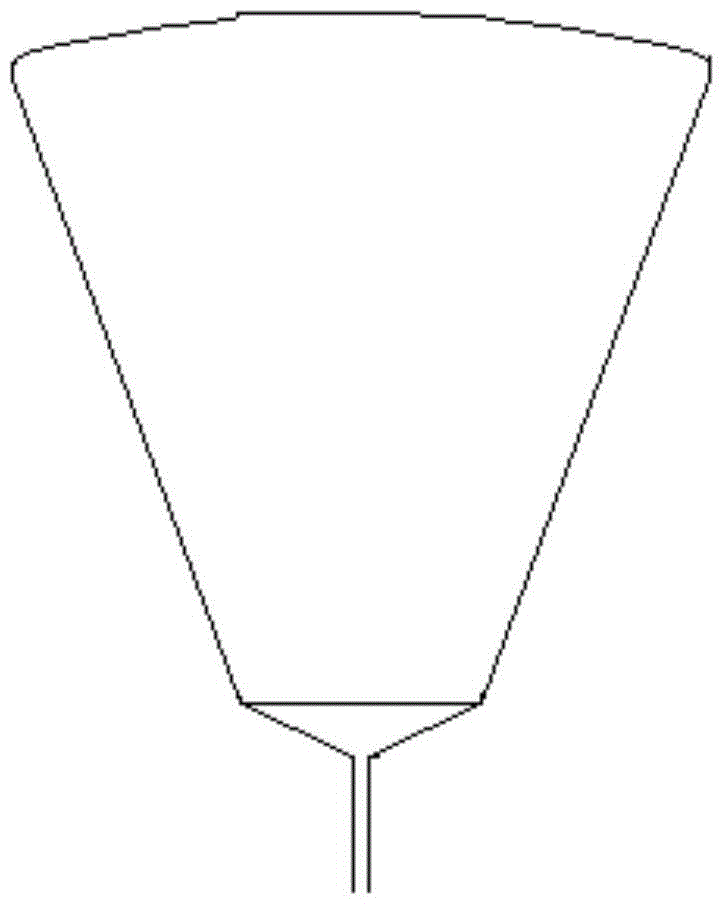

[0028] (4) Select the groove type as trapezoidal fan-shaped groove, and take the shoulder width of the groove Bottom width where h x1 is the groove shoulder depth, h 01 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com