Production method of radial forked block type salient pole rotor for driving motor

A technology for driving motors and salient pole rotors, which is applied in the manufacture of motor generators, stator/rotor bodies, electrical components, etc. Complicated problems, to achieve the effect of improved motor output performance, high production efficiency, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

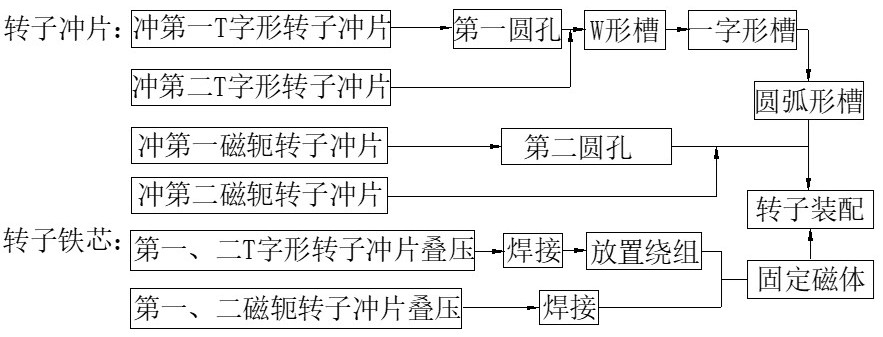

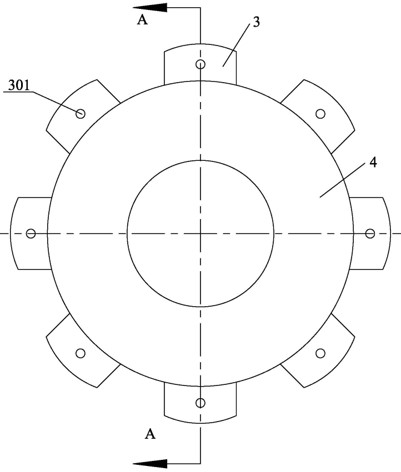

[0029] Such as Figure 1 to Figure 4 shown, including the following steps:

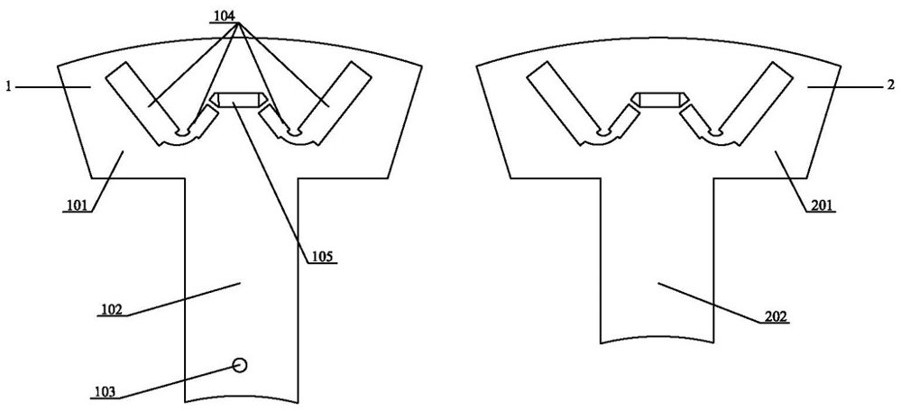

[0030] 1) Punching and cutting the first T-shaped rotor punching piece 1, the first T-shaped rotor punching piece includes the first pole piece 101 and the first pole body 102, the inner end of the first pole body 102 is provided with a first round hole 103, the first The inner side of the pole body 102 is set in a circular arc shape with a concave surface facing the center of the first T-shaped rotor punching plate 1. The first pole piece 101 is provided with a W-shaped groove 104 running through the axial thickness of the first pole piece 101. The W-shaped groove 104 It consists of two first rectangular grooves and two second rectangular grooves between the two first rectangular grooves, the length of the second rectangular grooves is less than the length of the first rectangular grooves, and the outer ends of the two second rectangular grooves are arranged There is an in-line groove 105 that runs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com