Fresh corn threshing machine

A technology for thresher and corn kernels, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of broken corn kernels, high price, low penetration rate, etc., and achieve complete threshing, simple structure and wide application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

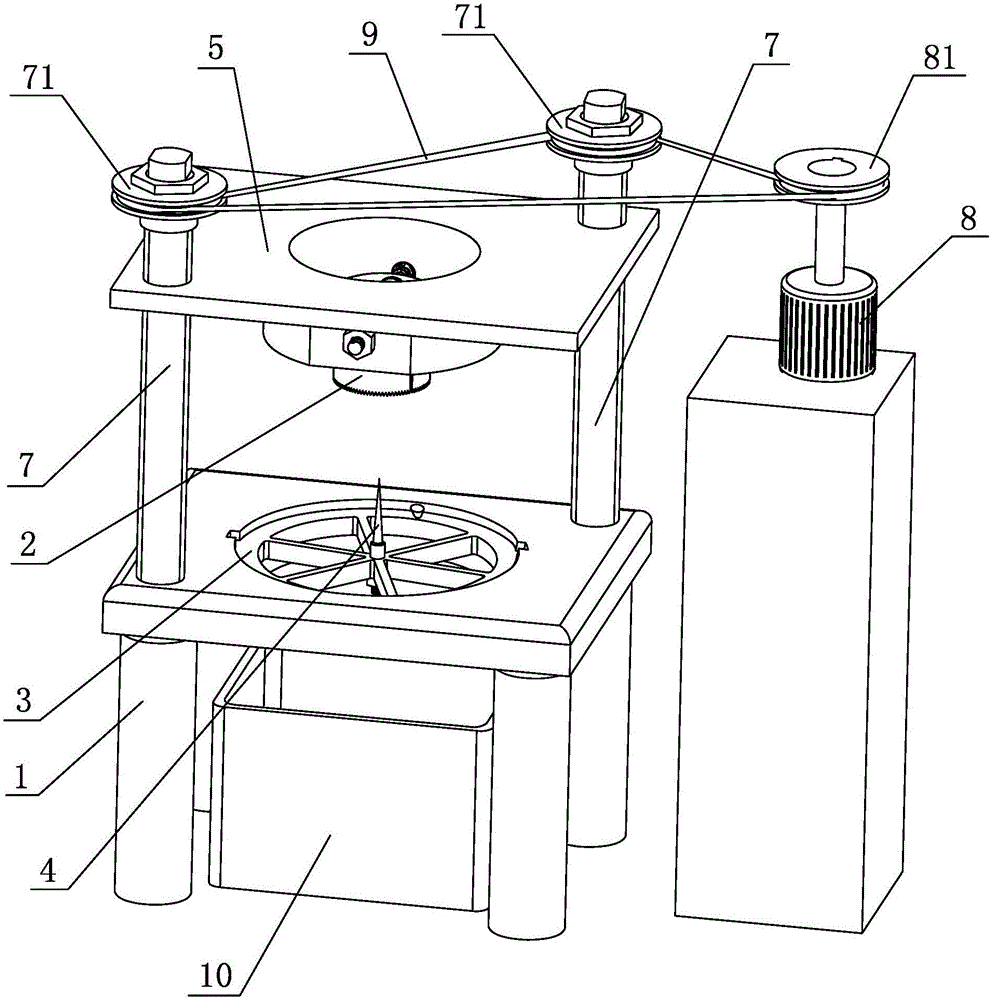

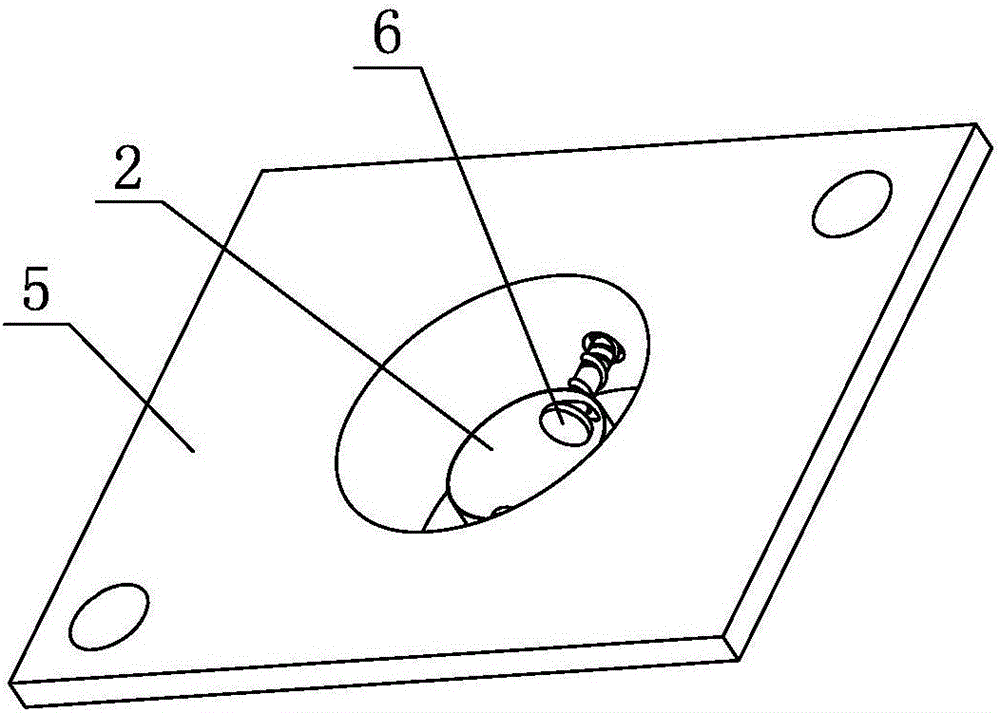

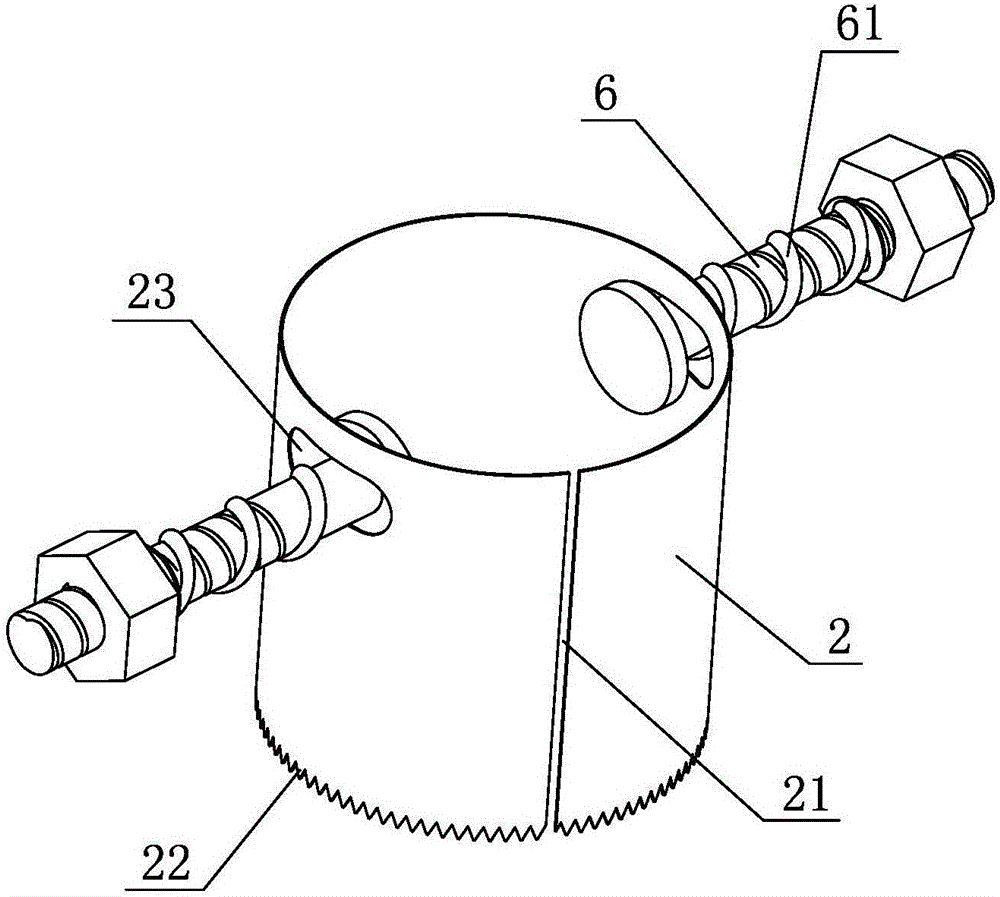

[0021] Embodiment 1: As shown in the figure, a fresh corn thresher includes a frame 1 and an annular blade 2 for cutting corn kernels. The annular blade 2 is provided with an axial slit 21, so that the annular blade 2 can Stretched, the inner diameter of the ring blade 2 is equal to or slightly smaller than the diameter of the head of the corn cob core in a natural state, the lower end of the ring blade 2 is integrally provided with a sawtooth blade 22, and the frame 1 is provided with a corn cob fixing mechanism and a blade Moving down the driving mechanism, the corn cob fixing mechanism includes a mounting plate 3 and a thimble 4, a mounting hole 11 is provided on the frame 1, and a gear protrusion ring 12 is integrally arranged in the mounting hole 11, and the mounting plate 3 is mounted on the gear protrusion ring 12 On, the mounting plate 3 is integrally provided with a positioning bump 31, the inner wall of the mounting hole 11 is provided with a positioning groove 13, th...

Embodiment 2

[0023] Embodiment 2: As shown in the figure, a fresh corn thresher includes a frame 1 and an annular blade 2 for cutting corn kernels. The annular blade 2 is provided with an axial slit 21, so that the annular blade 2 can Stretched, the inner diameter of the ring blade 2 is equal to or slightly smaller than the diameter of the head of the corn cob core in a natural state, the lower end of the ring blade 2 is integrally provided with a sawtooth blade 22, and the frame 1 is provided with a corn cob fixing mechanism and a blade Moving down the driving mechanism, the corn cob fixing mechanism includes a mounting plate 3 and a thimble 4, the mounting plate 3 is integrally connected with the frame 1, the thimble 4 is vertically arranged and screwed and fixed with the mounting plate 3, the tip of the thimble 4 faces upward, and the mounting plate 3 is provided with a plurality of blanking holes 32, and the blanking holes 32 are distributed around the thimble 4, and the bottom of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com