Agricultural corn kernel rapid threshing equipment

A corn kernel, fast technology, applied in threshing equipment, agriculture, agricultural machinery and implements, etc., can solve the problems of insufficient threshing, slow threshing speed, etc., to achieve the effect of easy classification and collection, easy operation and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

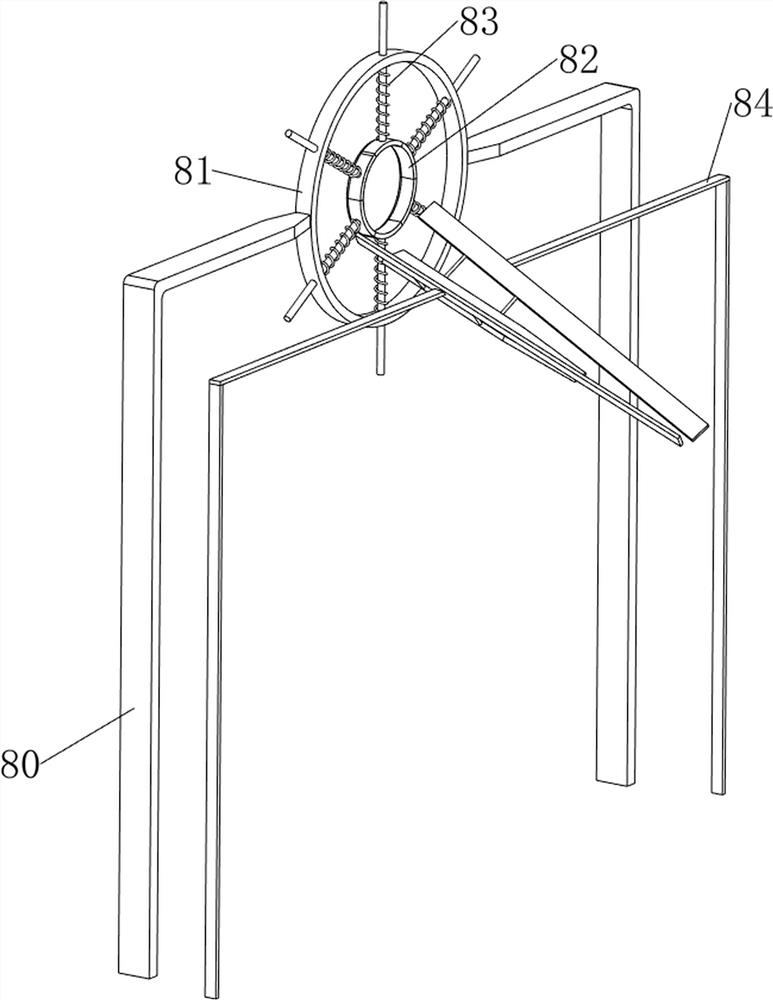

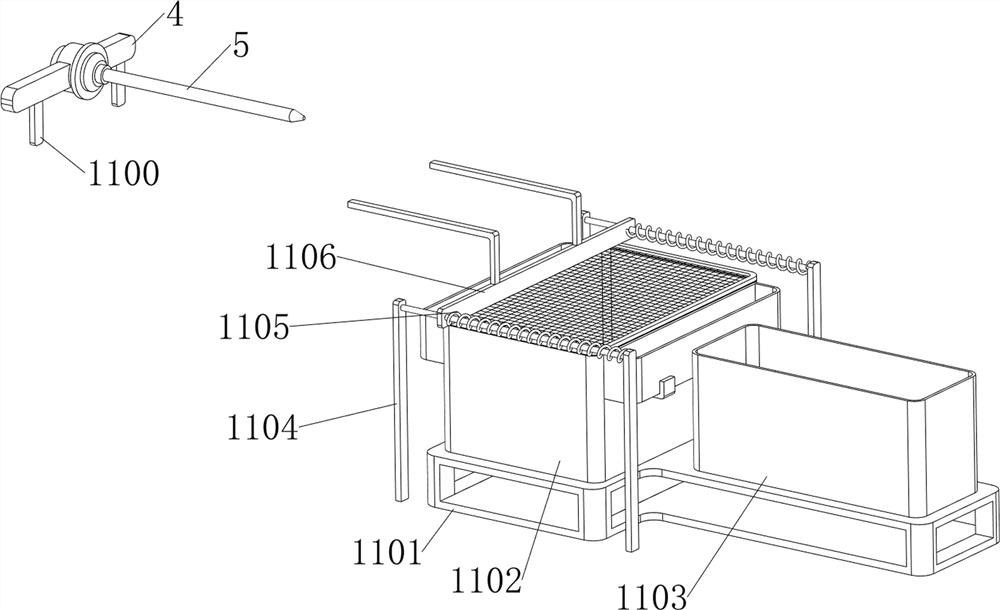

[0067] An agricultural corn kernel rapid shedding equipment, such as figure 1 , figure 2 and image 3 As shown, it includes a base plate 1, a support rod 2, a cylinder 3, a first fixed block 4, an iron needle 5, a placement frame 6, a rotating mechanism 7 and a peeling mechanism 8, and the peeling mechanism 8 includes a first support frame 80, a first Fixed ring 81, blade 82, the first spring 83 and sliding frame 84, base plate 1 top left side symmetrically is provided with support bar 2, is provided with cylinder 3 between support bar 2 tops, is provided with the first fixed on the cylinder 3 telescopic rods. Block 4, the rear part of the first fixed block 4 is rotatably provided with an iron needle 5, the middle of the top of the bottom plate 1 is provided with a shelf 6, the top left of the top of the bottom plate 1 is provided with a rotating mechanism 7, and the right side of the top of the bottom plate 1 is provided with a stripping mechanism 8 , the top right side of...

Embodiment 2

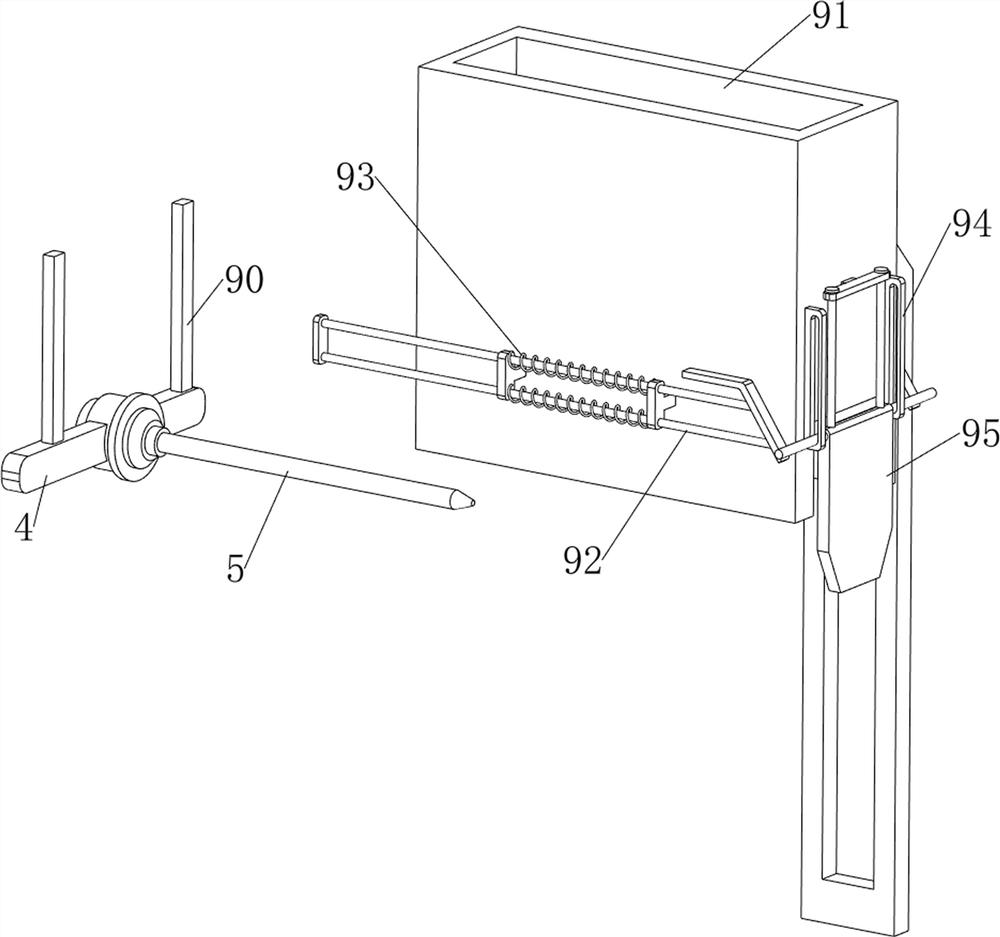

[0072] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, a baffle mechanism 9 is also included. A baffle mechanism 9 is provided between the first fixed block 4 and the base plate 1. The baffle mechanism 9 includes a fixed rod 90, a charging frame 91, a movable frame 92, and a second spring 93. , chute 94 and dodge door 95, the front and rear symmetry of the first fixed block 4 top is provided with fixed bar 90, is provided with charging frame 91 in the middle of bottom plate 1 top, and charging frame 91 bottom is provided with movable frame 92 front and back symmetrical sliding type, movable The frame 92 cooperates with the fixed rod 90, and the second spring 93 is arranged symmetrically up and down between the movable frame 92 and the charging frame 91. Dodge door 95 is arranged, and dodge door 95 cooperates with movable frame 92.

[0073] In the initial state, the movable door 95 is located at the lower side of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com