Automatic bean curd brine adding technology and equipment

A kind of process equipment and tofu technology, which is applied in the field of automatic control of tofu stewing, can solve the problems of unfavorable industrial production promotion and unsatisfactory effect of automatic quantitative stewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

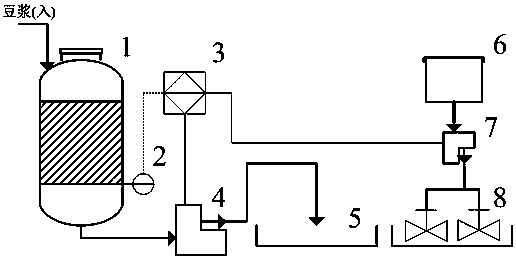

[0013] After the boiled soybean milk enters the buffer tank 1, the online concentration meter 2 detects the concentration of the soybean milk in real time, and transmits the result to the automatic control PLC3 for halogen pointing. According to the real-time data of soymilk concentration, automatic control PLC of soymilk adjusts the amount of soymilk filled by the soymilk quantitative pump 4 to the mature squatting box 5, so that it has a reasonable ratio with the constant amount of brine, so as to achieve the optimal brine Effect.

Embodiment 2

[0015] After the boiled soybean milk enters the buffer tank 1, the online concentration meter 2 detects the concentration of the soybean milk in real time, and transmits the result to the automatic control PLC3 for halogen pointing. According to the real-time data of soymilk concentration, automatic brine control PLC adjusts the amount of brine added by the brine quantitative pump 7 through the brine distributing agitator 8 in time to make it a reasonable ratio with the constant amount of soymilk, so as to achieve the optimal point halogen effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com